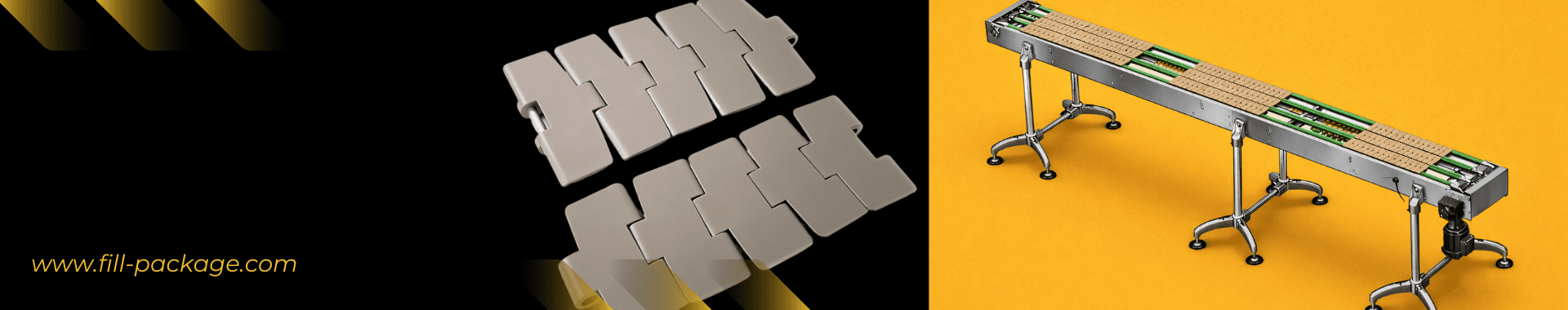

Flat Top Chains for Packaging Lines

Engineered for precision and stability, Flat top chains are the definitive solution for conveying rigid, upright products in demanding packaging lines. This overview introduces our comprehensive slat top chain solutions, available in both stainless steel and plastic, to guide you to the perfect material for your application.

Introduction: The Backbone of Stable Product Transfer

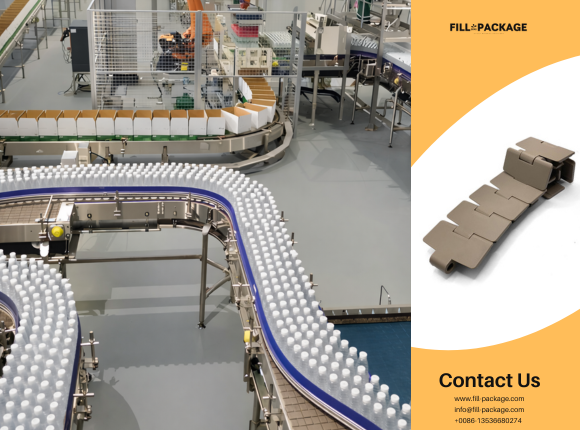

In the world of automated packaging, maintaining product orientation and stability is paramount. Slat top chains play a critical role in achieving this, serving as the backbone for conveying bottles, cans, and other rigid containers. Unlike flexible, belt-based conveying systems, slat top chains provide a solid, flat, and continuous surface that ensures products move smoothly and without tipping. They are the industry-standard solution for applications where stable product transfer is not just a preference, but a necessity.

What Are Slat Top Chains?

Also known in the industry as table top chains or slat chain conveyors, these systems consist of a series of interconnected, rigid top plates mounted on a drive chain. This unique construction creates a hard, flat conveying surface that is ideal for handling products with a defined, stable base. The rigid nature of the chain ensures precise movement and positioning, making it a perfect fit for automated filling, capping, labeling, and inspection lines where product placement is critical. This is the essence of rigid chain conveying.

They are commonly used in packaging lines where:

- Product orientation must be maintained

- Line stability is critical

- Continuous and predictable conveying is required

Key Advantages of Flat Top Chain Conveying

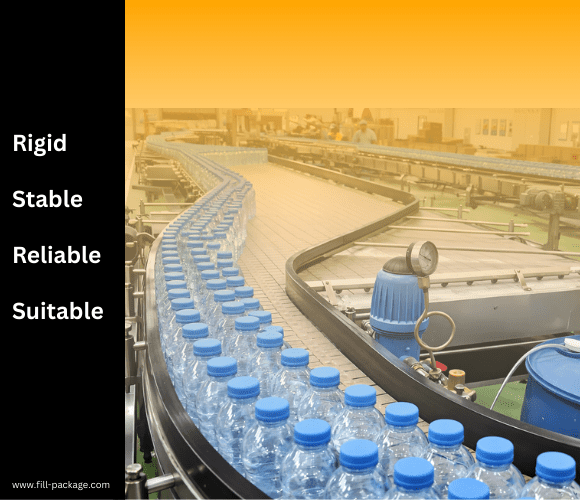

Rigid and Stable Product Transfer

Reliable Chain-Based Construction

Suitable for Compact and Flexible Layouts

Slat top chain conveyors can be configured in straight or curved sections, allowing packaging lines to adapt to space constraints and layout requirements without compromising product stability.

Material Options for Slat Top Chains: Stainless Steel vs. Plastic

Stainless Steel Slat Top Chains

- High-Temperature Environments: Such as pasteurization or sterilization tunnels.

- Corrosive Conditions: Handling acidic products or undergoing harsh chemical washdowns.

- Heavy-Load Applications: Where the strength of steel is required.

Plastic Flat Top Chains

- Food and Beverage Processing: Made from FDA-compliant materials.

- High-Speed Conveying: Their low-friction surface allows for higher speeds and reduced energy consumption.

- Low-Noise Environments: Plastic chains operate more quietly than their steel counterparts.

Typical Applications

- Bottle Conveying: Glass and plastic bottles in beverage, pharmaceutical, and cosmetic industries.

- Can Conveying: Aluminum and steel cans for food and beverage products.

- Rigid Containers and Cartons: Small boxes, jars, and other rigid packages.

- Transfer Between Packaging Machines: Seamlessly moving products between fillers, cappers, labelers, and case packers.

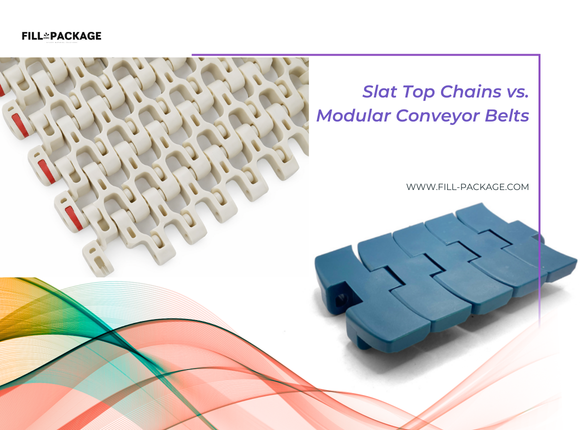

Slat Top Chains vs. Modular Conveyor Belts

Feature | Slat Top Chains | Modular Conveyor Belts |

Structure | Rigid, solid top plates | Flexible, interconnected modules |

Best For | Rigid, stable, upright products | Varied product sizes, shapes, and weights |

Stability | Excellent, maintains orientation | Good, but less rigid |

Adaptability | Limited to straight or side-flexing lines | Highly adaptable to inclines, declines, and complex layouts |

Integration with Packaging Equipment

- Filling, Capping, and Labeling Lines: Providing the stable platform needed for these precision operations.

- Transfer and Take-Away Sections: Efficiently moving products into and out of machines like case packers or shrink wrappers.

Choose the Right Slat Top Chain Solution

- Product Characteristics: Is your product rigid, stable, and upright? Does it have a defined base?

- Operating Environment: Will the chain be exposed to high temperatures, moisture, or corrosive chemicals?

- Performance Requirements: Do you need high speed, low noise, or heavy-load capacity?

Related Product

A slat top chain, also known as a table top chain or table top chain, is a type of conveyor chain that features a flat, solid carrying surface. It is constructed from a series of interconnected rigid plates, creating a smooth and stable platform ideal for conveying products that need to remain upright, such as bottles, cans, and jars.

The main advantage is stability. The rigid, flat surface of a slat top chain is superior for maintaining the orientation of tall, narrow, or unstable products. While modular belts are more versatile for handling varied product shapes and complex layouts (like inclines), slat top chains excel at providing a consistently stable platform, which is critical in high-speed filling, capping, and labeling lines.

- High-Temperature Environments: Such as pasteurization tunnels or hot-fill applications.

- Corrosive Conditions: When the chain is exposed to acidic products or harsh chemical washdowns.

- Heavy-Load or High-Wear Applications: Where the superior strength and durability of steel are required for long-term reliability.

- Food Contact is Required: Plastic chains are made from FDA-compliant materials.

- High-Speed Conveying is Needed: Their low-friction surface allows for faster line speeds and lower energy consumption.

- Quiet Operation is a Priority: Plastic chains operate more quietly than their steel counterparts, contributing to a better working environment.

- Cost-Effectiveness is a Factor: Plastic chains are generally more economical for standard applications.

Yes, in addition to straight-running chains, there are side-flexing slat top chains specifically designed to navigate curves. This allows for the creation of complex conveyor layouts that can adapt to facility space constraints without needing to transfer products between separate conveyors, thereby maintaining product stability throughout the entire line.

- Glass and plastic bottles

- Aluminum and steel cans

- Jars and other rigid containers

- Small, stable cartons or boxes

Slat top chains are designed for seamless integration with standard packaging machinery. They are commonly used as the primary conveying surface for:

- Filling and capping machines

- Labeling systems

- Inspection and rejection stations

- Transfer and take-away sections between different machines

- Product: What are you conveying? (e.g., bottles, cans, cartons)

- Environment: What are the operating conditions? (e.g., temperature, moisture, chemicals)

- Performance: What are your line requirements? (e.g., speed, layout, noise level)