When it comes to packaging sticky, wet, or difficult-to-flow products, a standard multihead weigher often falls short. That’s where the screw feeder multihead weigher comes in—a specialized family of combination weighers designed to handle the most challenging materials in food packaging and beyond.

In this comprehensive guide, we’ll explore the various types of screw feeder weighers, their unique features, and how to choose the right configuration for your product.

What Makes a Screw Feeder Multihead Weigher Different?

A screw feeder multihead weigher (also known as a screw feeder combination weigher) is not a single machine—it’s a diverse family of weighing solutions. Each configuration is engineered to address specific product challenges, from sticky sauces and marinated meats to delicate vegetables and fragile snacks.

The key difference lies in how these multi head weighers transport product through the system. Instead of relying solely on vibration, they incorporate screw conveyors that actively move sticky or clumping materials, ensuring consistent flow and accurate weighing.

Understanding the Basic Structure

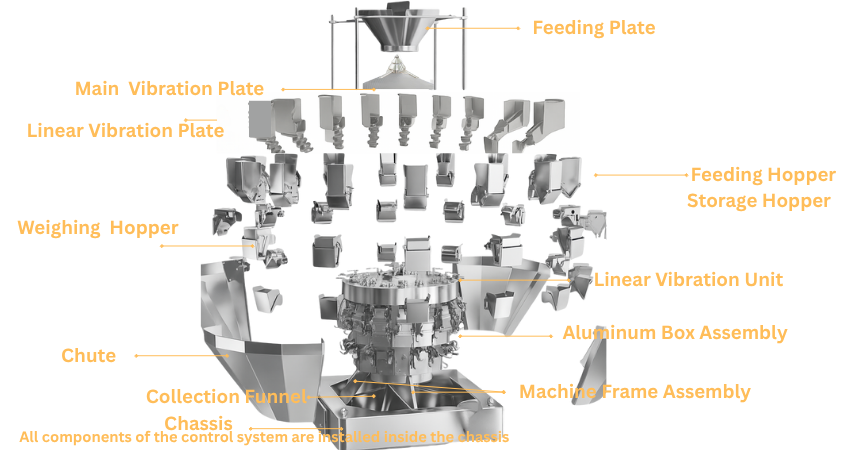

Before diving into classifications, let’s understand the core components of a multihead weigher with screw feeder:

Component | Function |

Feed Plate | Receives bulk product from upstream equipment |

Main Vibration Plate | Distributes product evenly across the system |

Main Vibrator | Powers the central distribution system |

Linear Feeder Plate | Transport product to individual weigh buckets |

Linear Vibrator Assembly | Controls product flow rate to each bucket |

Feeding Hoppers | Temporarily hold product before weighing |

Weighing Hoppers | Precision weighing chambers with load cells |

Aluminum Box Assembly | Houses motors and sensors for bucket actuation |

Discharge Chute | Guides weighed product to packaging machine |

Machine Frame Assembly | Structural support for the entire system |

Collection Funnel | Collects combined product from multiple buckets |

Chassis (Control Cabinet ) | Contains main controller, driver boards, and power supply |

Classification 1: Surface Treatment Options

The contact surface of your combination weigher has a significant impact on product flow. Here are the main options:

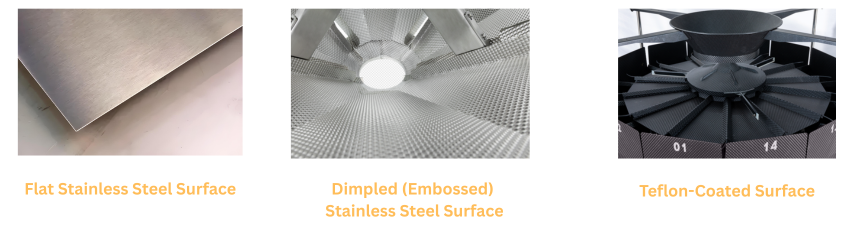

Flat Stainless Steel Surface

Best for: Free-flowing or moderately sticky products

- Standard 304 stainless steel

- Smooth, easy-to-clean surface

- Cost-effective option

- Suitable for products like dry snacks, nuts, or lightly coated items

Dimpled (Embossed) Stainless Steel Surface

Best for: Sticky or wet products

- Reduces contact area between product and surface

- Minimizes friction and sticking

- Created through embossing process with specialized dies

- Pattern varies by manufacturer (small dimple, honeycomb dimple, etc.)

- Ideal for marinated meats, cheese, wet vegetables

Teflon-Coated Surface

Best for: Extremely sticky or adhesive products

- Applied to either flat or dimpled stainless steel

- Maximum non-stick performance

- Essential for products like sauces, sticky candies, or heavily marinated items

- Requires periodic re-coating depending on usage

Pro Tip: Many modern multi weigher systems combine dimpled surfaces with Teflon coating for ultimate anti-stick performance.

Tip 💡: Modern multihead weighing systems often combine dimpled surfaces with Teflon coating for ultimate anti-stick performance.

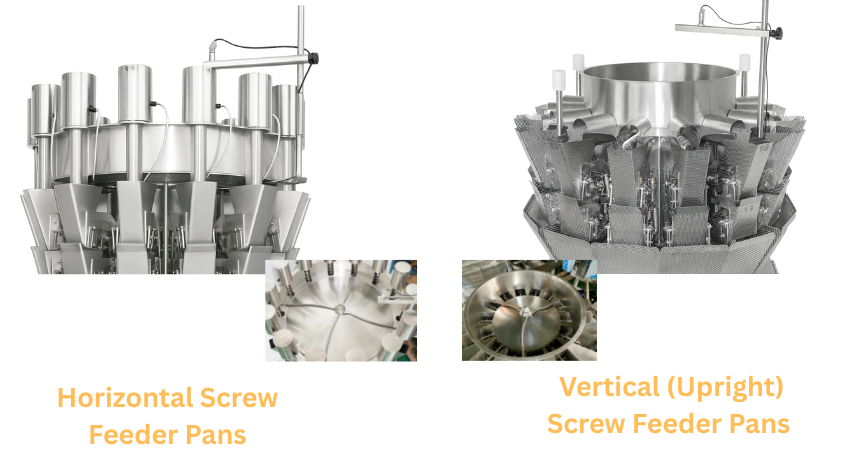

Classification 2: Screw Feeder Pan Configurations

The orientation and design of screw feeders in your multihead weigher determine how effectively it handles your specific product.

Horizontal Screw Feeder Pans

The most common configuration for screw feeder combination weighers.

Vertical (Upright) Screw Feeder Pans

Best for: Short, wet, oil-coated products

- Applications: Radish cubes, pickled vegetable stems, wet pasta

- Advantages: Excellent drainage, prevents product clumping

- How it works: Vertical screws lift product upward before dropping into weigh buckets

- Unique benefit: Gravity assists in separating sticky pieces

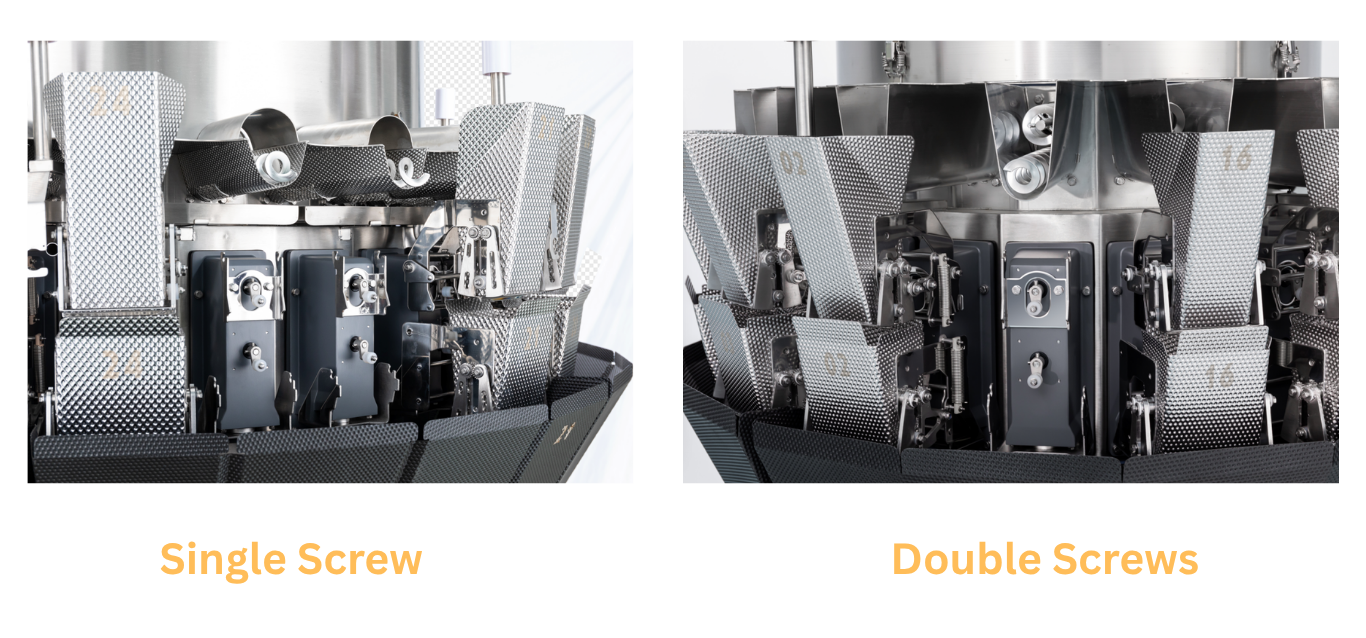

Single Screw

- Best for: Larger pieces with moderate stickiness

- Applications: Diced meat, chicken chunks, vegetable pieces

- Advantages: Gentle product handling, less product damage

- Speed: Moderate to fast

Double Screw

- Best for: Highly sticky or fibrous products

- Applications: Marinated radish strips, squid strips, spicy fish, sauced noodles

- Advantages: Anti-tangling design, prevents product bridging

- Speed: Moderate (prioritizes accuracy over speed)

Key Difference: The main vibration pan and linear feeder pans in vertical screw weighers are oriented differently than horizontal models, creating a distinct product flow pattern.

Classification 3: Hopper Opening Systems

How your multi head weigher releases product is critical for accuracy and cleanliness.

Standard Double-Door Hoppers

- Design: Two pneumatic doors open simultaneously

- Best for: Free-flowing products

- Limitation: May leave residue with sticky products

Scraper-Style Double-Door Hoppers

- Design: Doors with integrated scraper blades

- Best for: Sticky, adhesive, or wet products

- Advantages: Ensures complete product discharge, Prevents residue buildup, Maintains weighing accuracy, Improves hygiene, and reduces waste

Why it matters: Even small amounts of residue can affect the next weigh cycle’s accuracy

Industry Standard: Most screw feeder combination weighers now use scraper-style hoppers as the default configuration.

Classification 4: Discharge Chute Designs

The discharge chute is where your weigher hands off product to the packaging machine—and it’s often the largest contact surface with sticky materials.

Surface Options

- Dimpled stainless steel – Good for moderately sticky products

- Dimpled + Teflon coating – Better for very sticky products

- Flat stainless steel + Teflon coating – Best for liquid-like products

Structural Configurations

Multi-Panel Chute (3-4 Panels) Design: 3-4 stainless steel panels form a single large chute

Advantages:

- Universal fit for various products

- Lower cost

- Easier to manufacture

Disadvantages:

- Larger internal volume may cause the product to swirl or tumble

- Less precise product placement

- Potential for product damage

Individual Chute System

- Design: Each row of weigh buckets has its own dedicated chute

- Advantages: Product slides down like individual slides, Minimal product interaction ,Precise placement into bags or containers, Reduced product damage, Better for delicate items

- Best for: Premium products, delicate items, or when precise bag placement is critical

- Trend: Individual chute systems are becoming the preferred choice for high-value products and applications requiring maximum accuracy.

Choosing the Right Screw Feeder Multihead Weigher Configuration

Not sure which multi weigher configuration you need? Here’s a quick decision guide:

For Sticky Meat Products (Marinated Chicken, Beef, Pork)

- Screw Type: Horizontal single screw

- Surface: Dimpled stainless steel

- Hopper: Scraper-style double door

- Chute: Individual chutes with a dimpled surface

For Super-Sticky Products (Sauced Noodles, Marinated Vegetables)

- Screw Type: Horizontal double screw

- Surface: Dimpled + Teflon coating

- Hopper: Scraper-style double door

- Chute: Individual chutes with Teflon coating

For Wet, Oil-Coated Products (Pickled Vegetables, Wet Pasta)

- Screw Type: Vertical screw

- Surface: Dimpled stainless steel

- Hopper: Scraper-style double door

- Chute: Multi-panel or individual, depending on product fragility

For Moderately Sticky Products (Cheese, Dried Fruit)

- Screw Type: Horizontal single screw

- Surface: Flat or small dimple stainless steel

- Hopper: Standard or scraper-style double door

- Chute: Multi-panel chute (cost-effective option)

The Evolution Continues

The screw feeder multihead weigher family is constantly evolving. As new products enter the market and packaging requirements become more demanding, manufacturers develop new configurations and features.

Recent innovations include:

- Hybrid screw-vibration systems that switch modes based on product behavior

- Self-cleaning screw designs that reduce maintenance time

- Modular screw assemblies that allow quick changeovers between products

- Smart sensors that detect product buildup and adjust screw speed automatically

https://youtube.com/shorts/01MLpE3_TqM

Need Help Choosing?

Selecting the right screw feeder combination weigher requires understanding your product’s unique behavior. At Fill Package, we test your actual product in our facility before recommending a configuration—because no two sticky products behave the same way.

Contact us to discuss your specific application and receive a customized weigher recommendation based on real-world testing.

E-mail:[email protected]

Whatsapp:+86-13536680274

Related Resources

•Multihead Weigher Product Page – Explore our full range of weighers

•Sticky Product Packaging Guide – Complete guide to handling difficult materials