Introduction

In our previous blog, “How to Choose the Right Packaging System – The Ultimate Guide”, we walked you through the strategic framework for selecting a complete packaging production line.

This supplementary guide takes a deeper look at the technical specifications of each core component. By presenting side-by-side comparisons, material guidelines, and optimization strategies, we aim to give decision-makers a practical reference tool when evaluating and configuring their packaging line.

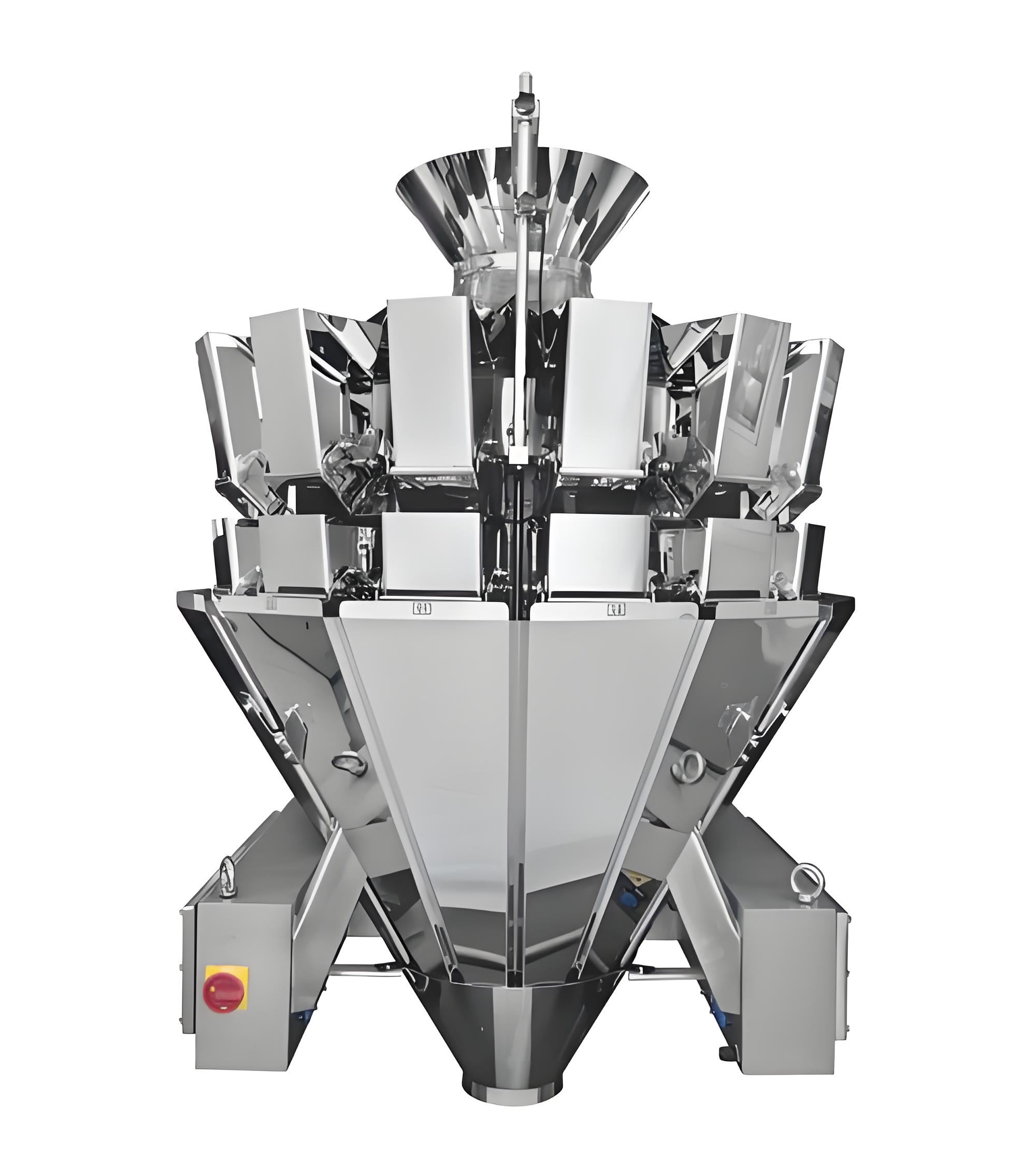

Whether you are considering a VFFS packaging machine, modular belt conveyor, multihead weigher, or metal detector, this guide provides the data-driven insights you need to balance performance, cost, and long-term ROI.

Packaging Machines: Comparative Overview

| Packaging Machine Type | Suitable Products | Packaging Speed | Accuracy Level | Investment Cost | Maintenance Complexity | Packaging Materials | Typical Applications |

|---|---|---|---|---|---|---|---|

| Vertical Form Fill Seal (VFFS) | Granules, powders, liquids | 20–120 bags/min | High | Medium | Medium | Composite film, aluminum foil film | Snacks, seasonings |

| Pre-made Pouch Packaging Machine | High-end products | 30–80 bags/min | Very high | High | Medium | Pre-made pouches | Nuts, pet food |

| Horizontal Form Fill Seal (HFFS) | Bars, blocks | 40–200 packs/min | High | High | Medium | PE film, composite film | Bakery, soaps |

| Multihead Weigher System | Granules, irregular pieces | 30–200 packs/min | Very high | High | Medium | Multiple | Broad food categories |

Conveyors: Technical Parameters

| Conveyor Type | Load Capacity | Speed | Hygiene Grade | Maintenance Frequency | Suitable Environment | Cost Index |

|---|---|---|---|---|---|---|

| Flat Belt Conveyor | 0.5–50 kg/m | 5–60 m/min | IP65 | Monthly | Dry/lightly damp | 100 |

| Chain Conveyor | 10–200 kg/m | 3–30 m/min | IP67 | Quarterly | Heavy load, washdown | 150 |

| Roller Conveyor | 5–100 kg/m | 10–80 m/min | IP54 | Monthly | Dry | 120 |

| Screw Conveyor | 1–20 t/h | Variable | IP67 | Monthly | Powder handling | 180 |

Metal Detectors: Performance Parameters

| Channel Size | Ferrous Detection | Non-Ferrous Detection | Stainless Steel Detection | Conveyor Speed | Typical Applications |

|---|---|---|---|---|---|

| 100×50 mm | ≥0.8 mm | ≥1.0 mm | ≥1.5 mm | ≤30 m/min | Small packs |

| 200×100 mm | ≥1.0 mm | ≥1.5 mm | ≥2.0 mm | ≤25 m/min | Medium packs |

| 400×200 mm | ≥1.5 mm | ≥2.0 mm | ≥2.5 mm | ≤20 m/min | Large packs |

| 600×300 mm | ≥2.0 mm | ≥2.5 mm | ≥3.0 mm | ≤15 m/min | Industrial |

Working Platforms: Material Selection Guide

| Industry | Recommended Material | Surface Finish | Protection Grade | Expected Lifespan | Cost Factor | Special Requirements |

|---|---|---|---|---|---|---|

| Food Processing | 304 SS | Brushed/Polished | IP65 | 15–20 yrs | 2.5 | FDA compliant |

| Pharmaceuticals | 316L SS | Electro-polished | IP67 | 20–25 yrs | 3.5 | GMP compliant |

| Chemicals | 316 SS | Acid-passivated | IP67 | 15–20 yrs | 3.0 | Corrosion resistant |

| General Industry | Q235 Carbon Steel | Powder coated | IP54 | 10–15 yrs | 1.0 | Cost effective |

System Integration & Optimization: The 1+1 > 2 Effect

Key Principles

- Standardized Interfaces – Ensure mechanical, electrical, and communication interfaces are aligned.

- Unified Control System – A centralized PLC/HMI for seamless monitoring and control.

- Data Connectivity – Enable real-time production tracking and traceability.

Performance Optimization

- Takt Time Balancing – Simulations to eliminate bottlenecks.

- Buffer Zones – Build resilience against process fluctuations.

- Preventive Maintenance – Data-driven strategies to minimize downtime.

ROI Analysis Model

Direct Benefits

- Labor savings: reduce packaging staff by 60–80%

- Reduced product giveaway: 2–5% savings

- Production efficiency: 50–200% throughput increase

Indirect Benefits

- Enhanced product consistency

- Stronger brand perception

- Improved traceability and compliance

Payback Period: 1.5–3 years (depending on scale and industry)

Conclusion

While the ultimate guide provides a roadmap for choosing your packaging system, this supplementary blog serves as a reference manual for comparing technologies, specifications, and trade-offs.

At Fill-Package, we specialize in delivering complete food packaging solutions—from belt conveyors and modular chain conveyors to multihead weighers, pouch packaging machines, checkweighers, and metal detectors.

👉 If you want to explore how these components can be tailored into a turnkey solution for your factory, contact us at www.fill-package.com.