In today’s fast-paced manufacturing environment, efficiency and precision are critical to a business’s success. Whether you’re in food processing, pharmaceuticals, or hardware packaging, precise weighing is essential for product quality, cost control, and brand reputation. Traditional weighing methods are no longer sufficient for modern production lines that demand both high speed and high accuracy.

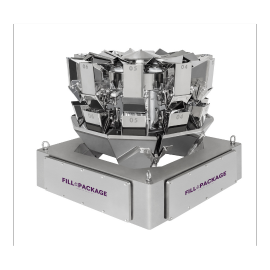

Enter the multihead weigher—also known as a combination scale—an intelligent solution that’s revolutionized the way industries manage portioning and packaging. As a key part of modern packaging machinery, these systems are designed for rapid, highly accurate weighing of a wide range of materials—granular, strip-like, blocky, or irregularly shaped—making them indispensable for automated packaging systems.

In this comprehensive guide, you’ll learn everything you need to know about multihead weighers—from their working principles and core technologies to selection standards and industry applications. If you’re looking for a reliable multihead weigher manufacturer or just trying to decide between a high-precision multihead weigher, a screw feeder multihead weigher, or a unit suitable for sticky materials, this article will give you the insights you need to make an informed purchase decision.

🧠 Inside the Heart of It All: How a Multihead Weigher Works

To understand why multihead weighers are so powerful, we must first look at their operating principle: combination weighing. Imagine needing to weigh exactly 500 grams of potato chips per bag. Doing this manually would be time-consuming and error-prone. A multihead weigher, however, automates this process with high precision and speed:

The Workflow:

- Feeding & Distribution

The product is transported via an elevator or conveyor system to the top of the weigher, where it’s evenly distributed to multiple vibrating feeders. - Controlled Feeding

Each linear feeder directs product into an individual weigh hopper using vibration, preparing it for high-precision weighing. - Individual Weighing

Each hopper is equipped with a high-accuracy sensor that instantly records the product weight. - Smart Combination Calculation

A central processing unit (CPU) quickly calculates the best combination of hoppers to get as close as possible to the target weight—say 500g—choosing, for example, 120g from hopper 1, 205g from hopper 5, and 175g from hopper 8. - Discharge

Once the optimal combo is found, those hoppers open simultaneously, releasing the product into the VFFS packaging machine or sachet packaging machine below. - Repeat Process

New product is immediately refilled into empty hoppers, and the next cycle begins. This cycle repeats continuously at speeds of 60–120+ weighments per minute, depending on your packaging machinery setup.

This process ensures consistent weight per package, minimizes waste, and enables high-throughput production. The multihead weigher is the core of any food packaging machine line where speed and precision are non-negotiable.

🎯 Choosing the Right Multihead Weigher for Your Business

Not all weighers are created equal. Selecting the best model for your application is a strategic decision. Here’s what you need to consider:

1. Performance Specs: Accuracy, Speed & Stability

- Accuracy:

The high precision multihead weigher is ideal for high-value products. Evaluate specs like minimum division and average error. - Speed:

Measured in BPM (bags per minute), your production goals determine what you need. But remember, faster speed can sometimes reduce accuracy. - Stability:

Look for solid build quality, reliable sensors, and motors from trusted suppliers. Stable machines mean fewer downtimes.

2. Configuration: Heads, Hoppers, Materials

- Number of Heads:

More heads (e.g. 10, 14, 16, 24) offer more combinations = faster and more accurate weighing. However, more heads mean higher cost and maintenance. - ✔ Sticky products? Consider a multihead weigher for sticky products

✔ Powder or fragile items? Choose specific hopper types

✔ Sticky or flow-resistant materials? Try a screw feeder multihead weigher - Hoppers:

The shape, volume, and surface finish of hoppers must match your product. Coated hoppers for sticky products, cushioned designs for fragile goods, and large-volume hoppers for bulky items are all available. - Material:

For food and pharma use, SUS304 or SUS316 stainless steel is recommended for sanitary and corrosion-resistant packaging systems.

3. Smart Features & Connectivity

Modern industrial packaging equipment is as much about software as it is hardware.

- HMI (Human-Machine Interface):

Look for touchscreen interfaces, recipe storage, multi-language support. - Smart Functions:

Auto-zeroing, error alerts, data logging—these features reduce operator errors and support quality control. - Connectivity:

Can your weigher integrate with conveyor systems, metal detectors, printers, and other automated packaging systems? Does it support remote monitoring?

4. Choose the Right Manufacturer

Your supplier should be more than just a vendor—they should be a partner.

- Experience:

Has the manufacturer handled similar products? Can they show proven results? - Customization (ODM):

A good multihead weigher manufacturer should offer tailored solutions, not just off-the-shelf machines. - Support & Service:

From system design and installation to training and after-sales support, you need a partner that stays involved.

🌍 Applications: From Food to Pharma and Beyond

Multihead weighers are most common in the food packaging machinery industry, but their reach extends far beyond:

🥗 Food Industry:

- Snacks (chips, popcorn, crackers)

- Confectionery (candies, chocolates, gummies)

- Nuts & seeds (almonds, sunflower seeds, mixed nuts)

- Frozen foods (dumplings, vegetables, seafood)

- Cereals, oats, coffee beans

- Pet food packaging systems

These often use VFFS packaging machines or sachet packaging machines for final sealing.

🧪 Non-Food Sectors:

- Hardware (screws, bolts, fittings)

- Pharma (capsules, pills, herbal medicine)

- Cosmetics (bath salts, detergent pods)

- Agriculture (fertilizer, seeds, animal feed)

Multihead weighers excel in these applications due to their versatility and integration capabilities with industrial packaging equipment.

🤝 Not Just a Supplier — A Long-Term Packaging Machinery Partner

Choosing the right packaging machinery is a major decision. We don’t just deliver machines—we deliver complete automated packaging systems tailored to your business goals.

Here’s why you can trust us:

- Deep Experience:

We’ve worked with startups and Fortune 500 companies alike, across various product types and industries. - Customization Expertise:

Whether it’s hopper design, control software, or system layout, we provide OEM & ODM services for full customization. - Comprehensive Service:

From consulting and design to on-site setup, training, and technical support—we are with you every step of the way.

💬 Want to Get Started?

Ask us anything, including:

- Which model is best for your product?

- How to integrate with your existing conveyor system?

- Case studies of successful implementations

- How to maximize ROI through parameter optimization

📞 Contact us at:

Website: www.fill-package.com

Email: [email protected]

Phone: +86-13536680274

Bottom Line

A multihead weigher is more than just a component—it’s the heartbeat of your modern food packaging machines and automated packaging systems. From increasing productivity to reducing product giveaway, choosing the right weigher impacts every part of your business.

We hope this guide helps you better understand your options and prepares you to make an informed decision. If you’re ready to move forward, reach out to us—we’re here to be your trusted packaging machinery partner.

📌 FAQs

Q1: What is the difference between a multihead weigher and a linear weigher?

A: Multihead weighers are faster and more accurate, making them ideal for high-speed production lines. Linear weighers are simpler and more cost-effective for low-volume needs.

Q2: What types of products can be weighed with a multihead weigher?

A: Everything from snacks and candies to screws, pills, and pet food.

Q3: How much does a multihead weigher cost?

A: Multihead weigher price varies based on configuration, features, and manufacturer. Contact us for a customized quote.

Q4: Can it handle sticky or oily products?

A: Yes. For these, choose a multihead weigher for sticky products with special coatings or screw feeders.

Q5: How does a screw feeder multihead weigher work?

A: It uses a screw mechanism to control sticky or clumpy materials, improving flow and weighing precision.

Q6: What are the maintenance requirements?

A: Regular cleaning, sensor calibration, and occasional part replacement are key to long-term performance.

Q7: Is integration with packaging machines difficult?

A: Not at all. Our systems are designed for seamless integration with VFFS packaging machines, sachet packaging machines, and other conveyor systems.

Q8: Can you offer custom-built solutions?

A: Absolutely. As an experienced multihead weigher manufacturer, we offer complete ODM and OEM solutions.