In the world of industrial machinery, especially in the high-speed, high-precision packaging sector, it’s often the largest, most complex systems that get all the attention. However, the stability, longevity, and even the performance of these machines rest on one of the most overlooked components: The machine foot.

Also known as a leveling foot or support foot, this humble component is the critical interface between a multi-ton machine and the factory floor. For machine manufacturers and parts wholesalers, understanding the nuances of machine feet is not just a matter of hardware selection; it’s about ensuring machine reliability, reducing service calls, and delivering a superior product.

This guide will walk you through the essential classifications, applications, and selection criteria for machine feet, with a special focus on the models most commonly used in the packaging industry.

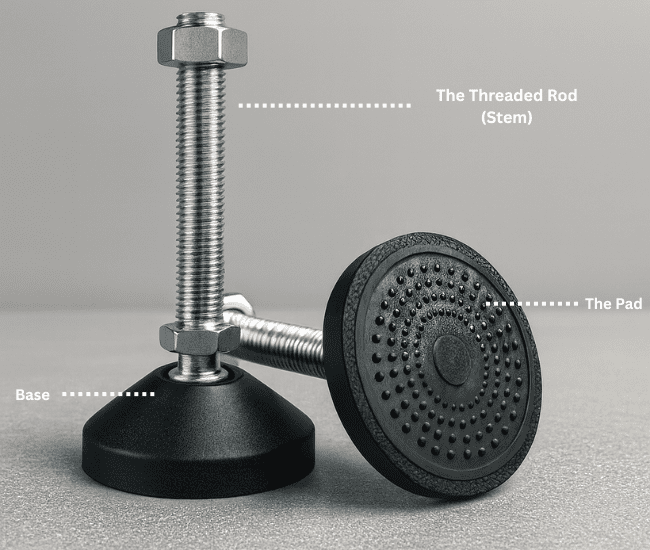

The Anatomy of a Machine Foot

At its core, a machine foot consists of three main parts:

- The Base: The load-bearing foundation that rests on the floor. Its diameter and material are critical for stability and load distribution.

- The Threaded Rod (Stem): The adjustable steel rod that screws into the machine frame, allowing for precise height adjustment and leveling.

- The Pad: An optional but often crucial layer on the bottom of the base, typically made of rubber or polyurethane (PU), designed to absorb vibration and prevent slipping.

Classifications: Finding the Right Foot for the Job

Machine feet can be categorized based on their function, load capacity, and material. For the packaging industry, these are the most relevant types:

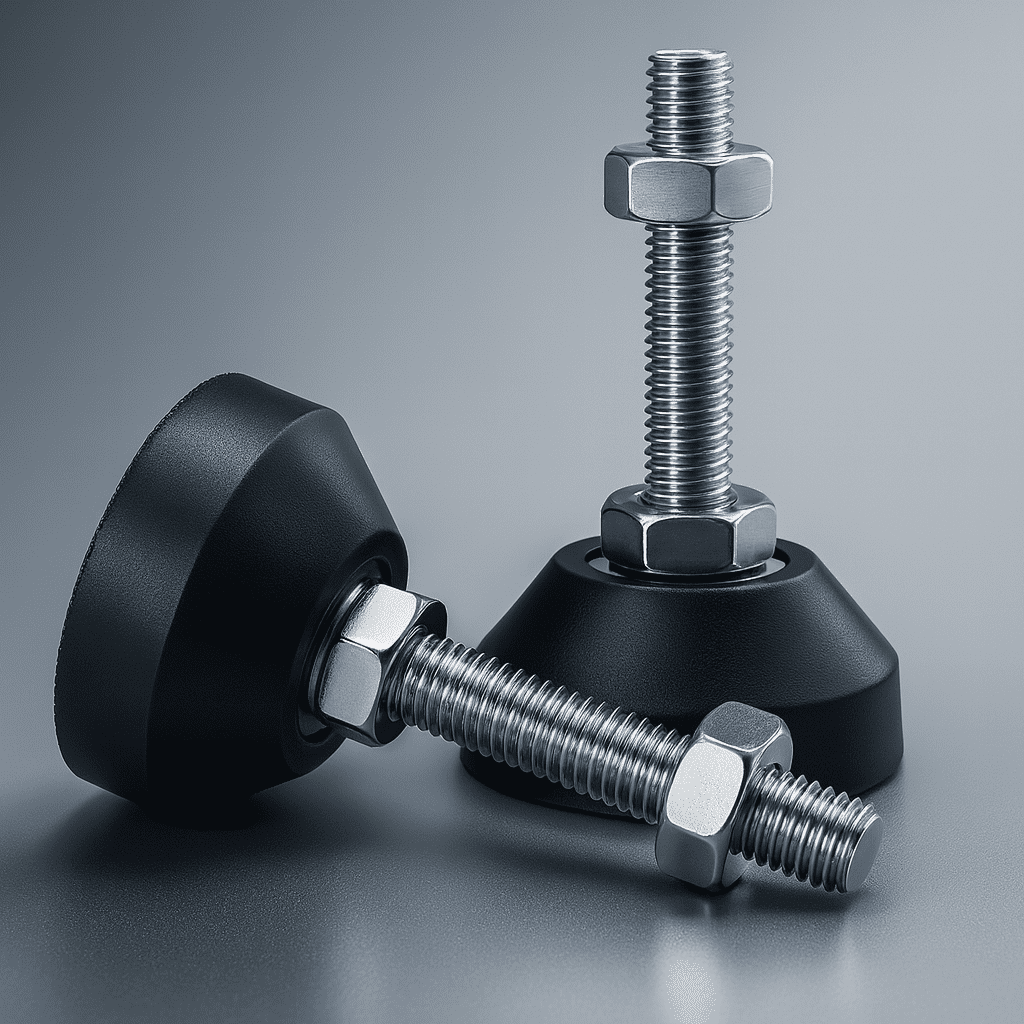

1. Standard Adjustable Leveling Feet

These are the workhorses of the industry, found on everything from conveyor belts to VFFS machines. They offer the essential ability to level equipment on uneven factory floors, which is critical for ensuring smooth operation and proper alignment between different machines in a production line.

- Common Base Diameters: 80mm and 100mm are popular choices. An 80mm base is a versatile, compact option for lighter equipment, while a 100mm base provides a larger footprint for enhanced stability on medium-weight machines like flow wrappers and labelers.

- Common Thread Size: The M16 threaded rod is a widely adopted standard for this category, offering an excellent balance of strength and adjustment range for a majority of packaging machines.

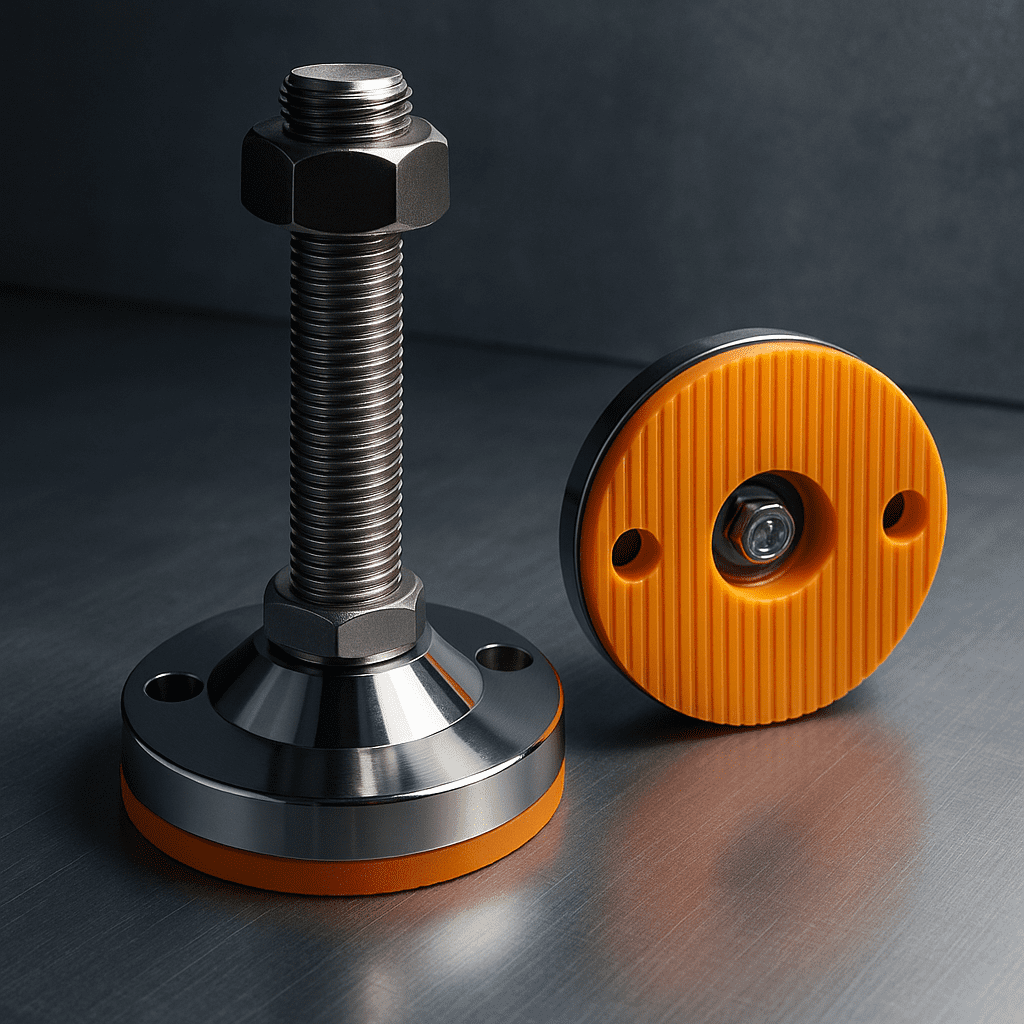

2. Heavy-Duty Machine Feet

When dealing with heavier equipment like case packers, palletizers, or large-scale filling lines, a standard foot is not enough. Heavy-duty feet are engineered for extreme loads and high-vibration environments.

- Key Features: They feature a significantly thicker base, a larger diameter threaded rod (e.g., M20, M24), and often include dual locking nuts to prevent any loosening due to vibration.

- Load Capacity: These can support several tons per foot, ensuring the absolute stability of the heaviest machinery.

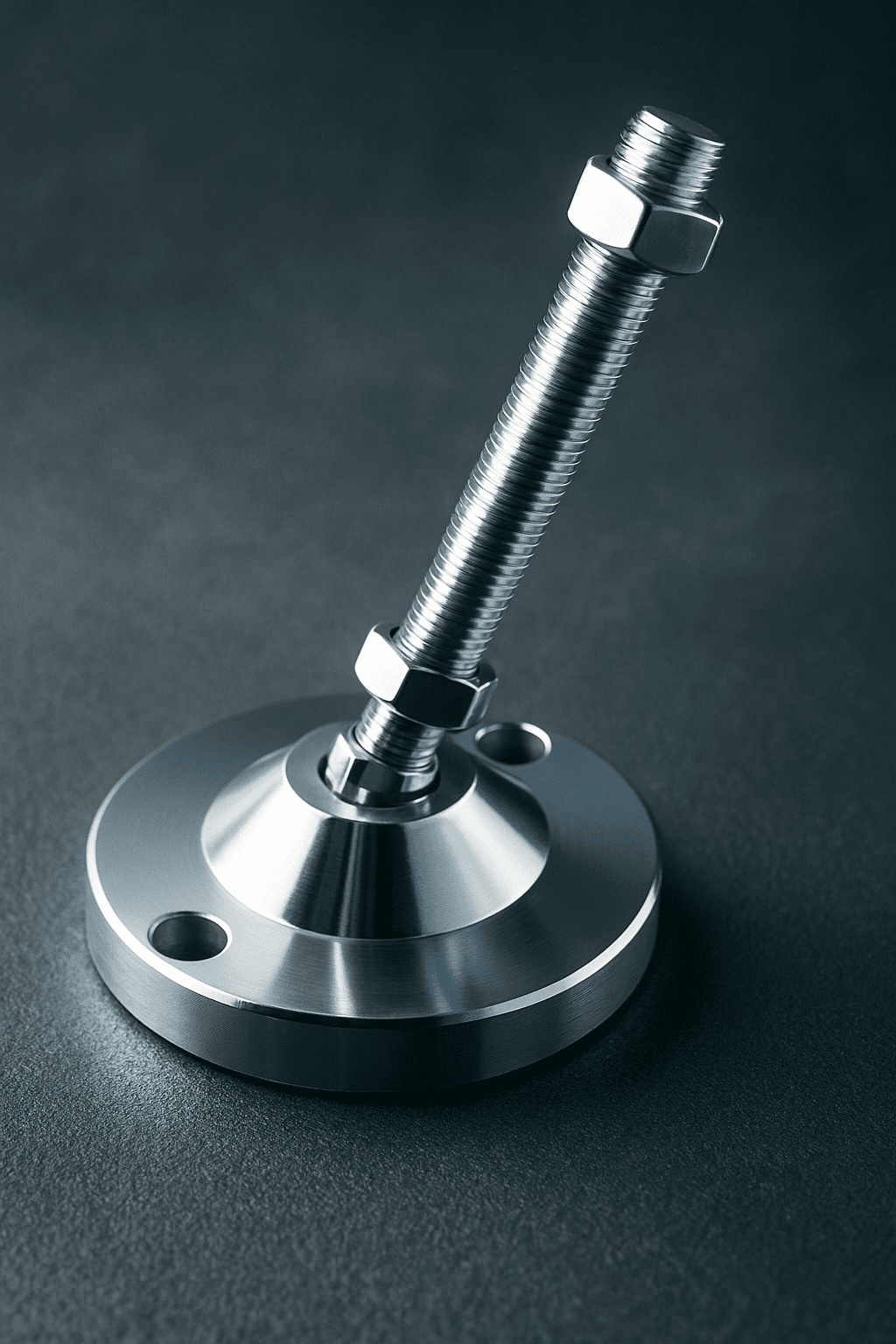

3. Hygienic & Sanitary Machine Feet (Food Grade/Stainless Steel Adjustable Feet)

In the food, beverage, and pharmaceutical industries, hygiene is non-negotiable. Sanitary machine feet are designed to prevent bacterial growth and withstand aggressive washdown procedures.

- Material: Made almost exclusively from high-quality SUS304 Stainless Steel.

- Design: They feature smooth, polished surfaces, sealed joints (where the rod meets the base), and no exposed threads to eliminate areas where water and bacteria can accumulate.

4. Swivel (Articulating) Feet

These feet have a ball-joint mechanism that allows the base to tilt, typically up to 10-20 degrees. They are the ideal solution for factory floors that are significantly sloped or uneven, as they ensure the base remains flush with the floor for maximum stability.

Load Capacity Calculation: Engineering the Right Support

One of the most critical aspects of machine foot selection is ensuring that each foot can safely support its share of the machine’s weight. Underestimating this can lead to foot failure, machine instability, and potential safety hazards.

Understanding the Safety Factor

The safety factor is a multiplier applied to account for dynamic loads (such as vibration, impact, or product weight fluctuations) and uneven weight distribution across the machine’s feet. For industrial applications, a safety factor of 1.5 to 2.0 is standard practice.

The Calculation Formula

Single Foot Minimum Load Capacity = (Total Equipment Weight × Safety Factor) / Number of Feet

Practical Example

Let’s say you are designing a case packer that weighs 2000 kg and will be supported by 4 machine feet. Using a safety factor of 1.5:

Single Foot Minimum Load Capacity = (2000 kg × 1.5) / 4 = 750 kg per foot

Therefore, you should select machine feet with a rated load capacity of at least 750 kg each. In practice, it’s wise to choose a foot with a capacity slightly above this minimum to provide an additional margin of safety.

A 5-Step Selection Process for Machine Feet

Selecting the right machine foot is a systematic process. Follow these five steps to ensure you make the optimal choice for your equipment.

Step 1: Equipment Analysis

Begin by gathering all relevant information about the machine:

- Total Weight: What is the complete weight of the machine, including all installed components?

- Footprint: How many feet will the machine have, and where will they be positioned?

- Operating Conditions: Will the machine generate vibration? Is it in a washdown environment?

Step 2: Determine Requirements

Based on the analysis, define your specific needs:

- Load Capacity: Use the calculation formula above to determine the minimum load capacity per foot.

- Environmental Factors: Do you need corrosion resistance (stainless steel) or vibration damping (rubber pads)?

- Adjustability: Does the machine need to be leveled frequently, or is a fixed foot acceptable?

Step 3: Initial Model Selection

Narrow down your options based on the requirements. For example:

- For a medium-weight packaging machine in a standard factory environment, an adjustable foot with a 100mm base and M16 thread is a strong starting point.

- For a food processing environment, prioritize SUS304 stainless steel hygienic feet.

Step 4: Calculation Verification

Apply the load capacity formula to verify that your selected model can safely support the machine. Additionally, check the manufacturer’s specifications for:

- Maximum Load Rating

- Thread Engagement Depth (ensure your machine frame can accommodate it)

- Adjustment Range (ensure it provides sufficient height adjustment)

Step 5: Final Confirmation

Before placing an order, double-check:

- Compatibility: Does the thread size match your machine frame’s tapped holes?

- Material Suitability: Is the material appropriate for the operating environment?

- Supplier Reputation: Are you sourcing from a reliable supplier with quality certifications?

Real-World Applications in the Packaging Industry

To make the selection process even more concrete, here are typical machine foot configurations for common packaging equipment:

Equipment Type | Recommended Foot Specification | Quantity | Notes |

80mm base, M12 thread | 4 | Lightweight, adjustable for easy leveling | |

Automatic Case Sealer/Conveyor Belt | 100mm base, M16 thread | 6 | Medium-duty, adjustable for stability |

High-Speed Filling Machine | 100mm base, M16 thread, vibration-damping | 8 | High vibration, requires rubber/PU pads |

Large Labeling Machine | 120mm base, M20 thread | 6-8 | Medium to heavy-duty, enhanced stability |

Palletizer | Heavy-duty, 150mm base, M24 thread | 8-12 | Extreme load capacity, dual locking nuts |

100mm base, M16 thread, stainless steel (food grade) | 4-6 | Hygienic design for food contact |

Why Quality Machine Feet Are a Competitive Advantage

For machine manufacturers, investing in high-quality machine feet is an investment in your brand’s reputation.

- Enhanced Machine Performance: A stable machine vibrates less, allowing it to run at higher speeds with greater precision.

- Reduced Service Calls: Properly specified feet prevent long-term problems caused by instability, such as frame stress or component misalignment, leading to fewer warranty claims and service visits.

- Improved Perceived Quality: A machine that stands solid and level on robust, well-made feet instantly gives the customer a sense of quality and durability.

Conclusion: The Foundation of Excellence

Machine feet are far more than just a piece of hardware; they are the foundation upon which your machine’s performance and reliability are built. By understanding the different types, materials, and selection criteria—especially common specifications like 100mm/80mm bases and M16 threads—and by applying proper load capacity calculations, you can ensure that every machine you build or supply is stable, safe, and built to last.

Ready to find the perfect foundation for your equipment? Explore our comprehensive range of standard, heavy-duty, and hygienic machine feet on our Machine Foot product page or contact our technical experts for a personalized recommendation.