“We have a vertical packaging machine in our workshop that’s been causing constant trouble. The film pulling length is inconsistent, the sealing position is always off, and even after replacing the cutter and adjusting the photo-eye, nothing works. The biggest headache is the synchronous belt (film pulling belt). It wears outSeverely in less than a month and looks like it’s about to break again. Our production efficiency has taken a major hit. What on earth is the problem?”

This is a classic issue faced by Mr. Wang, a production manager at a food packaging plant. If you’re facing similar frustrations, this article is for you. The problem likely isn’t with the parts you keep replacing, but with the seemingly simple yet critically important transmission core—the timing belt.

Fault Diagnosis: A Check-up for Your Timing Belt Problems

Over 90% of timing belt failures stem from improper tension and poor alignment. Before you decide to buy a new belt, use the following chart to perform a quick health check on your machine.

Common Fault | Potential Root Cause | Solution & Inspection Steps |

Film Slipping, Inaccurate Length | 1. Tension too low: The belt cannot engage effectively with the pulley. |

- Severe tooth wear: The tooth profile has flattened, losing its grip.

- Oil or grease on the belt or pulley: Drastically reduces friction. | 1. Check Tension: Press the belt in the middle of its span; it should feel taut but not rigid.

- Inspect Tooth Profile: Compare the old belt with a new one to assess wear.

- Clean: Wipe the belt and pulleys with a dry cloth dampened with alcohol. | | Belt Tracking Off, Edge Wear | 1. Misalignment: The drive and driven pulleys are not on the same plane.

- Uneven tension: The tension is inconsistent across the belt’s width.

- Deformed pulley flange. | 1. Laser Alignment: Use a laser alignment tool to check the alignment of the two pulleys.

- Re-tension: Loosen the tensioning device, ensure even force distribution, and then re-tighten.

- Inspect Flange: Look for signs of impact or deformation on the pulley flange. | | Premature Belt Breakage or Cracking | 1. Tension too high: The belt is under excessive, prolonged stress, leading to fatigue failure.

- Shock loads: Frequent abrupt starts and stops.

- Incorrect belt selection (bending radius too small). | 1. Reduce Tension: Tighter is not better. Excessive tension drastically shortens belt life.

- Optimize Start/Stop: Check the PLC program to add acceleration/deceleration ramps.

- Verify Model: Ensure the belt model matches the machine’s design specifications. | | Excessive Operating Noise | 1. Tension too high.

- Misalignment.

- Worn belt or pulleys. | Follow the checks above; noise is often a symptom of one or more of these issues. |

Key Insight: Replacing a synchronous belt is a temporary fix. Finding and resolving the root cause of its abnormal wear is the permanent solution.

How to Decode Timing Belt Models: HTD vs. Trapezoidal

Choosing the right model is half the battle. Timing belts are primarily categorized into two types:

1.HTD (High Torque Drive) Round-Tooth Profile: e.g., 160-5M-30

- 160: Pitch length of 160mm

- 5M: Pitch code (5mm distance between tooth centers), M for Metric round tooth

- 30: Width of 30mm

- Features: Smooth transmission, lower noise, capable of transmitting higher torque. The mainstream choice for modern VFFS machines.

2.Trapezoidal-Tooth Profile: e.g., 240L, 480-H-100

- 240L: Pitch length code, circumference 640mm, 64 teeth.

- 480-H-100: Pitch length code (48 inches), H for Heavy (trapezoidal tooth), 100 for width (1 inch).

- Features: Excellent positioning accuracy, but can be noisier at high speeds.

Common VFFS Machine Selection Guide:

Model | Circumference | Teeth | Example Machine Application |

240L | 640mm | 64 | For machines with film width ≤ 420mm, e.g., Songchuan ZL220, Ruiji Jinhong RL420 |

270L | 685.8mm | 72 | – |

T10-560 | 560mm | 56 | T10 indicates a trapezoidal tooth with a 10mm pitch |

Purchasing Tip: When unsure of the model, the most reliable method is to measure the old belt’s circumference, width, and number of teeth, and observe whether the tooth profile is rounded (HTD) or trapezoidal.

Proper Installation & Maintenance: The Key to Extending Belt Life

Installation Method (Remove & Install)

- [Remove]: Power off! Remove the safety guard, loosen the motor’s mounting bolts, and move the motor to create slack in the belt. Never pry the belt off. It should be easy to remove. After removing the old belt, inspect its wear pattern—it can tell you a lot about issues with the drive system’s design or maintenance.

- [Install]: Ensure the new belt and pulleys are perfectly clean. Fit the new belt, then adjust the motor’s position to gradually apply tension until it’s correct. Finally, tighten the motor’s mounting bolts and replace the guard.

Cleaning Method

- Select a suitable replacement belt.

- Clean the belt and pulleys: Use a lint-free cloth dampened with a non-volatile cleaning fluid. Never use sandpaper or sharp objects to scrape the belt, as this will damage its surface.

- Keep it Dry: The belt must be completely dry before installation and use.

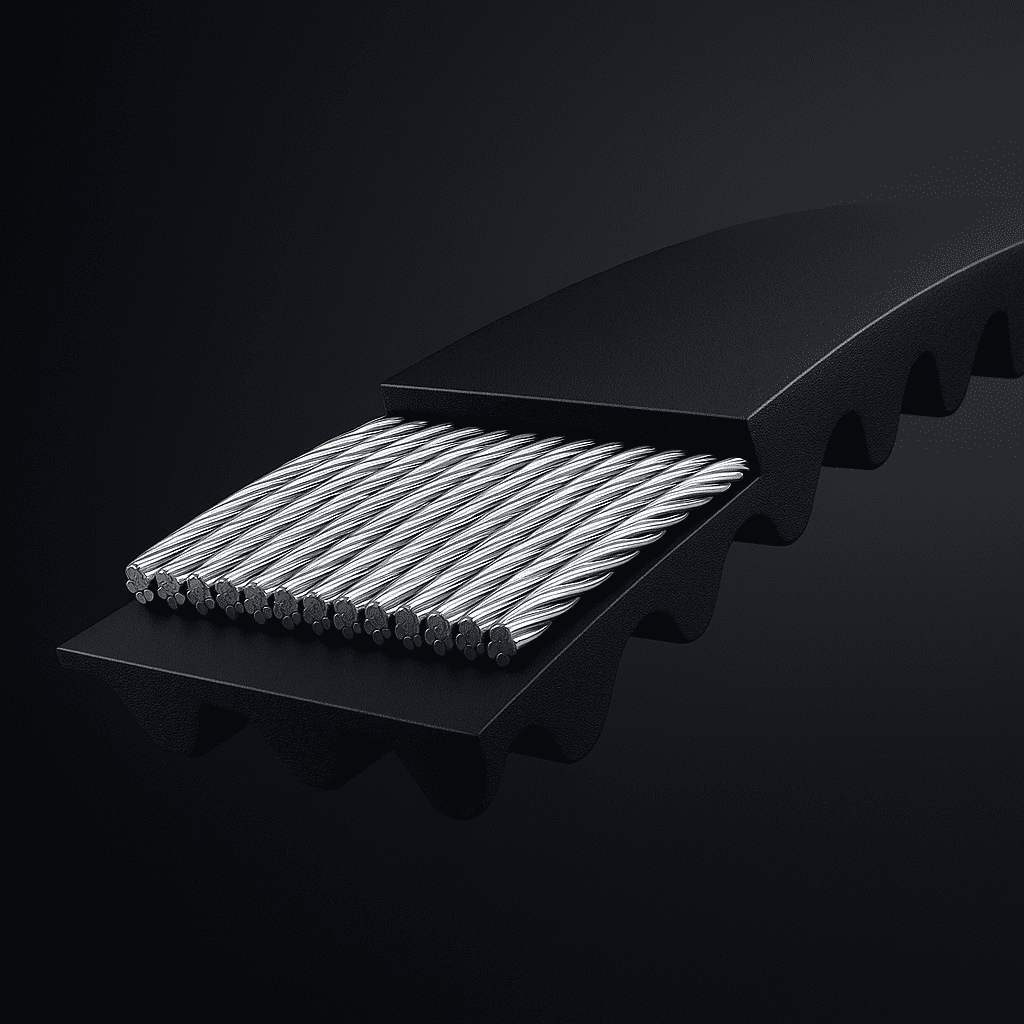

Core Features

- Ozone resistant, unaffected by tropical climates

- Anti-static properties meet ISO 9653 standards

These features ensure our synchronous belts maintain stable performance even in harsh industrial environments.

FAQ (Frequently Asked Questions)

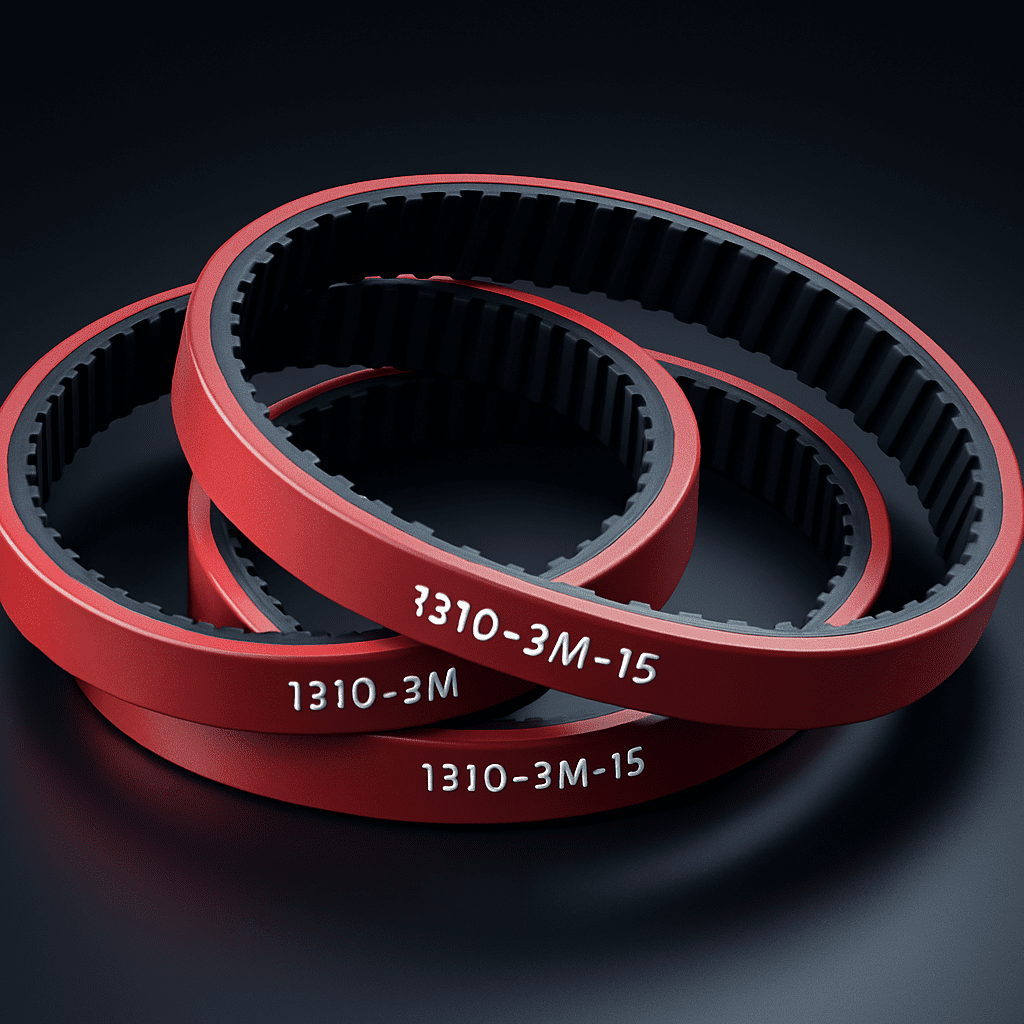

Q1: My belt is red. What’s the difference between it and a black one?

A: The color often indicates a different coating or material. For instance, a red surface may signify a rubber coating added to increase friction and improve grip on the packaging film, which is especially useful for smooth or heavy films. You should specify if you need this coating when purchasing.

Q2: Can I replace an HTD round-tooth belt with a trapezoidal-tooth belt?

A: Absolutely not. Different tooth profiles require matching pulley profiles. Mixing them will cause improper engagement, inaccurate transmission, and rapid damage to both the belt and the pulleys.

Q3: How long does it take to custom-make a special-sized belt?

A: In our experience, custom-made timing belts typically have a production lead time of about one week. Therefore, keeping a stock of critical wear parts for your key equipment is a very wise strategy.

Conclusion

A timing belt may be small, but it’s the nerve connecting power to action. One correct diagnosis and maintenance routine is far more valuable than ten blind replacements. We hope this article helps you solve your timing belt troubles at the source, restoring your packaging line to its original smooth and efficient state.

Need to find a high-quality replacement timing belt for your Songchuan, Ruiji Jinhong, or other VFFS packaging machine?

[Contact us today] with your machine model or belt specifications to get expert selection advice!