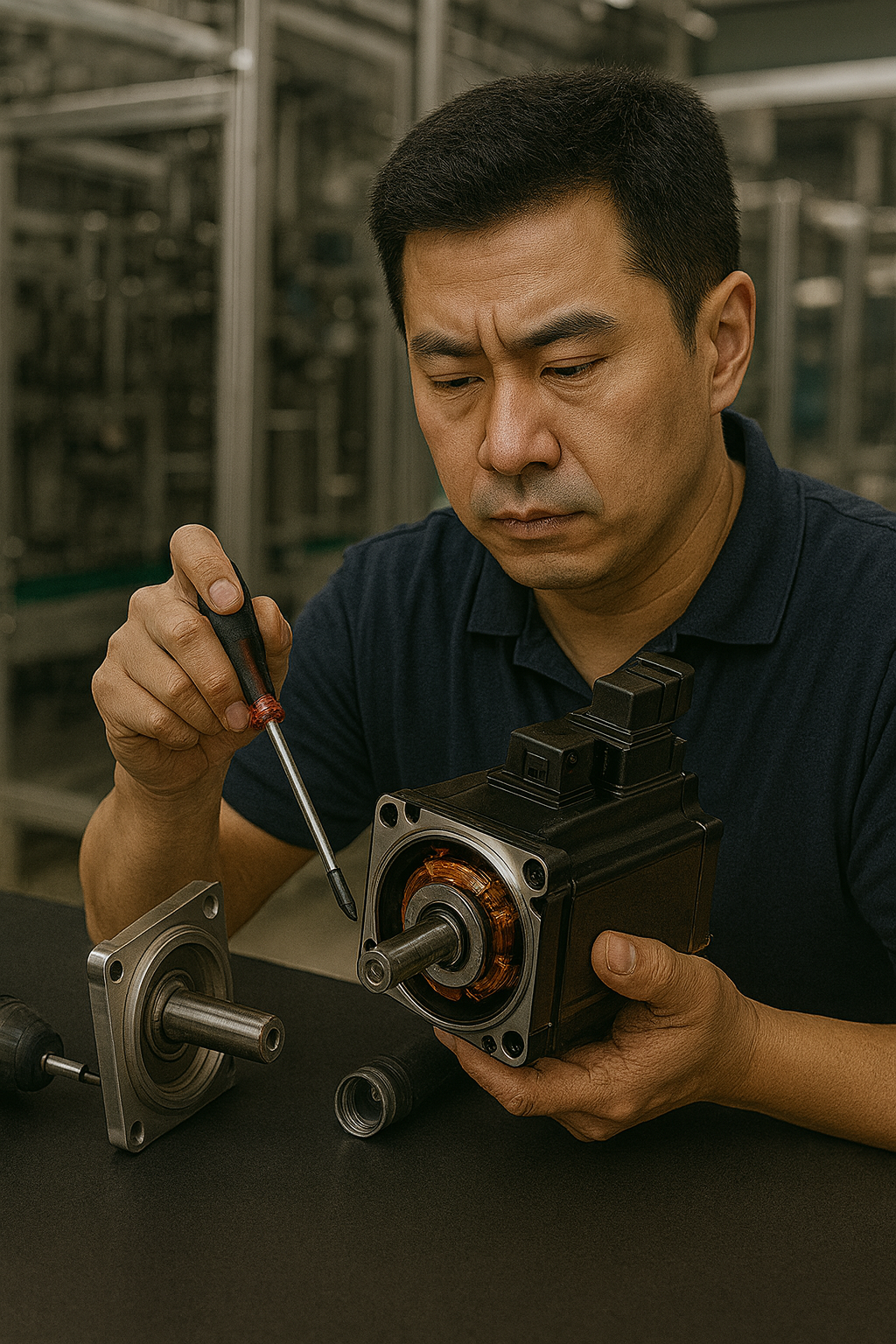

Is your servo motor really in good health?

- Does your equipment suddenly stop with cryptic alarm codes?

- Is your motor shaking, noisy, or losing precision day by day?

- Have you swapped spare parts only to face the same issue again?

If these situations sound familiar, you are in the right place. Servo motors are the heart of intelligent manufacturing, and their reliability directly affects production efficiency and product quality. Yet, in real-world operation, unexpected malfunctions and “mystery faults” appear frequently. From confusing overload alarms to positioning errors and vibration noise, every fault can cause costly downtime.

This article takes you inside a servo motor repair “clinic”, where we dissect real-world cases, reveal expert diagnostic methods, and offer proven solutions to recurring problems. Our goal is not only to solve your immediate failures but also to build an interactive platform where professionals can share experiences, ask questions, and improve together.

The Importance of Timely Servo Motor Repair

Servo motors are at the core of automation systems, CNC machines, packaging equipment, and robotics. Even a small fault can escalate into:

- Unplanned downtime leading to production delays.

- Reduced precision affecting product quality and causing rework or scrap.

- Increased maintenance costs from unnecessary part replacements.

- Safety risks due to uncontrolled movements or failures in critical systems.

Addressing servo motor issues requires not just replacing components but understanding root causes, adjusting parameters, and applying preventive measures. Let’s walk through practical fault cases and expert repair strategies.

Case 1: The Puzzling “No-Load Overload”

Patient profile: A 130-series servo motor in an automation line.

Symptoms: On power-up, the drive triggers an overload alarm, even with no load attached.

Step-by-Step Diagnosis

- Eliminate external load issues: With no mechanical load connected, excess torque was not the cause.

- Inspect power cabling: U, V, W phases were securely fastened with no visible wear.

- Check mechanical rotation: The shaft turned smoothly by hand with no binding.

Deeper Investigation

Connecting diagnostic software revealed abnormally high current draw and subtle high-frequency oscillation even at standstill. This pointed toward servo parameter misconfiguration.

Final Diagnosis

The speed loop gain was set excessively high. This amplified tiny disturbances into full oscillations, creating a hidden overload condition.

Solution

- Restore speed loop gain to factory defaults,

- Fine-tune incrementally to balance responsiveness and stability.

Result: The overload alarms vanished, and the motor resumed normal operation.

Interactive question: Beyond gain settings, what other internal servo drive faults could trigger “no-load overload”? Share your ideas in the comments.

Case 2: Annoying “Vibration and Noise”

Patient profile: 180-series servo motor in a CNC machine.

Symptoms: At high speeds, the motor produced a loud humming noise with severe vibration, reducing machining accuracy.

Initial Checks

- Mechanical alignment: Couplings were aligned, and ball screws lubricated.

- Cabling: The encoder cable was bundled with a high-power inverter cable — a potential EMI source.

Testing Hypothesis

Separating the encoder cable reduced interference, lessening vibration but not eliminating it. Oscilloscope readings exposed a resonance frequency in the system.

Final Diagnosis

The issue was a combination of electromagnetic interference and mechanical resonance.

Solution

- Rewire encoder cables separately with proper shielding and grounding.

- Activate notch filters in the drive to suppress the resonance frequency.

Result: Noise and vibration disappeared, restoring high-speed precision.

Interactive question: Have you used notch filters in your servo systems? Did they eliminate resonance effectively?

Case 3: Persistent “Positioning Inaccuracy”

Patient profile: 60-series servo motor in a packaging machine.

Symptoms: Long-term operation led to positioning drift, with errors worsening over time.

Diagnosis Path

- Mechanical inspection: Loose drive belts introduced backlash.

- Gain tuning: Increasing the position loop gain helped slightly, but didn’t cure the drift.

Advanced Investigation

After tightening the belts, errors persisted. Encoder data logs showed sporadic pulse losses, suggesting internal encoder damage or poor connections.

Final Diagnosis

The root cause was a combination of mechanical slack and a faulty encoder suffering from wear-induced data loss.

Solution

- Replace worn belts and tension them properly.

- Install a new encoder with secured connectors.

Result: Precision was restored, and long-run tests confirmed stability.

Interactive question: Apart from encoders and belts, what hidden factors in your experience have caused long-term positioning drift?

Common Servo Motor Repair Challenges

Beyond these cases, technicians frequently encounter:

- Overheating due to inadequate ventilation or excessive torque loads.

- Encoder misalignment leading to feedback mismatches.

- Parameter misconfigurations such as incorrect inertia settings.

- Power supply issues are causing intermittent resets or alarms.

Each requires a systematic root cause analysis, not quick fixes, to avoid repeat breakdowns.

Expert Troubleshooting Methodology

Experienced engineers follow a structured diagnostic approach:

- Symptom recording: Document alarms, sound, vibration, or irregular movements.

- Elimination process: Test load-free conditions, swap cables, or isolate drive modules.

- Parameter review: Validate tuning values against application requirements.

- Instrumented testing: Use oscilloscopes, vibration analyzers, or diagnostic software.

- Preventive action: Once fixed, adjust environment, cabling, or maintenance routines to avoid recurrence.

This logic-driven process ensures not only problem resolution but also long-term reliability.

Preventive Maintenance for Servo Motors

To minimize unexpected “mystery failures”:

- Regular inspection of cables, grounding, and shielding.

- Periodic tuning of control gains and filters.

- Thermal monitoring to prevent overheating damage.

- Mechanical maintenance on belts, couplings, and bearings.

- Clean operating environment to reduce dust and humidity-related faults.

Preventive care extends equipment life and safeguards productivity.

Free Expert Consultation – Solve Your Servo Motor Mysteries

Have you faced unsolved servo motor problems? Every case is unique, and generic manuals rarely address specific issues. That’s why we offer a free expert consultation service:

- Comment below with your problem details, including machine type, alarms, and attempted fixes.

- Email us at [email protected] with your case, and our engineers will analyze and advise.

Every inquiry is treated with professional care. Together, let’s conquer servo motor “mystery faults” and protect your production from costly downtime.