Plastic Flat Top Chains for Straight & Turning Conveyors

Engineered for versatility and efficiency, our plastic flat top chains deliver reliable performance across a wide range of packaging and conveying applications. From straight-running to side-flexing configurations, our comprehensive series offers the flexibility, hygiene, and low friction your production line demands.

Plastic Flat Top Chains for Packaging and Conveying

Key Advantages of Plastic Flat Top Chains

Low-Friction and Smooth Operation

Food-Grade and Hygienic Design

Versatile Straight-Running and Side-Flexing Capabilities

Lightweight and Cost-Effective

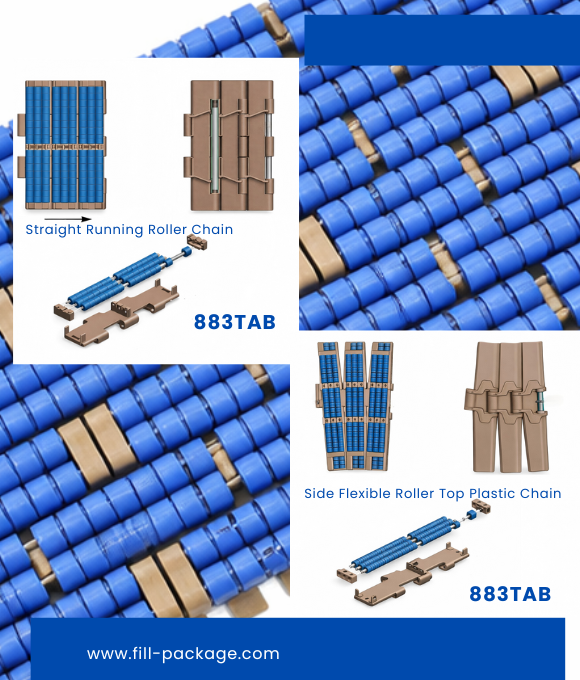

Our Plastic Flat Top Chain Series

Straight-Running Chains

Série | Principais características | Aplicações comuns |

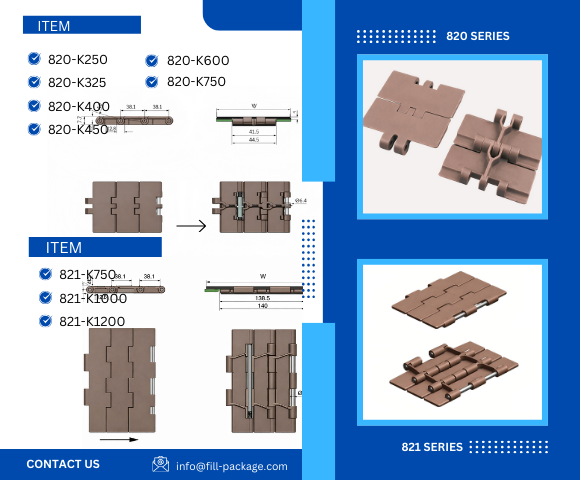

820 Series | Single hinge, 38.1mm pitch. The industry standard for straight-running applications. | Glass and PET bottle conveying, can manufacturing, general packaging. |

821 Series | Double hinge, 38.1mm pitch. Offers increased strength and rigidity for heavier loads. | Heavier containers, accumulation tables, case and box handling. |

Side-Flexing (Turning) Chains

Série | Principais características | Aplicações comuns |

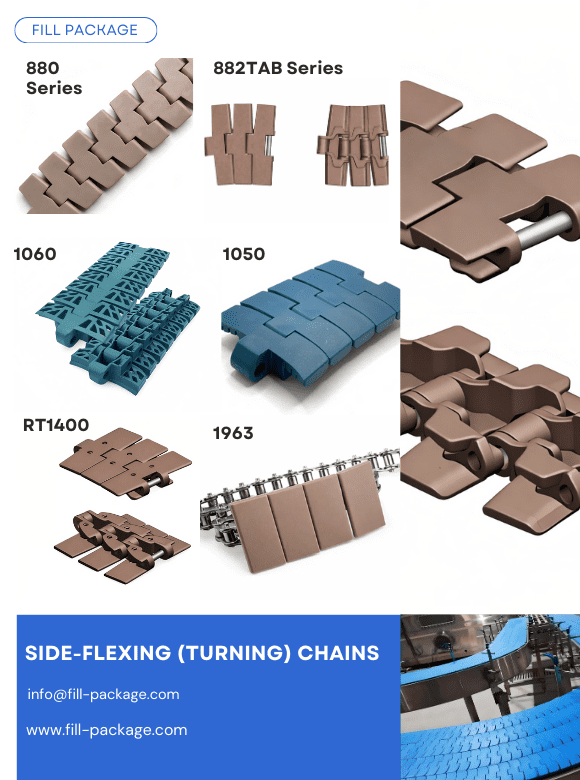

880 Series | 38.1mm pitch. The most popular side-flexing series with a tight turning radius. | Curved sections in bottling and canning lines, alpine accumulators. |

882TAB Series | 38.1mm pitch. A wider, heavier-duty version of the 880 series for larger products. | Multi-pack conveying, tissue roll handling, wide product transfer. |

1050/1060 Series | Unique 25.4mm (1-inch) pitch. Heavy-duty, side-flexing design. | Demanding applications requiring a smaller pitch with high strength. |

1963 Series | 38.1mm pitch. A robust design for medium-duty side-flexing applications. | General purpose conveying, case and box turning conveyors. |

RT1400 Series | 38.1mm pitch. A less common but effective side-flexing option. | Specific OEM machine de |

Auxiliary & Transition Chains

Material Options for Optimal Performance

Applications Across Industries

- Beverage Production: Transporting glass bottles, PET bottles, and aluminum cans through filling, capping, labeling, and packing.

- Processamento de alimentos: Moving packaged goods, trays, and containers in hygienic environments.

- Embalagem: Handling cartons, boxes, shrink-wrapped products, and flexible packages on primary and secondary packaging lines.

- Produtos farmacêuticos: Conveying vials, bottles, and cartons in cleanroom environments.

Produto relacionado

A plastic flat top chain, also known as a plastic tabletop chain or slat top chain, is a rigid, chain-based conveying solution made from engineered polymers like Acetal (POM ). Unlike modular belts, these chains feature a continuous, flat surface that provides stable product transfer, making them ideal for packaging lines, beverage production, and food processing applications.

Plastic flat top chains offer several key advantages. They are significantly lighter, reducing energy consumption and simplifying machine design. They have a lower coefficient of friction, which minimizes backline pressure and product damage. They are also more cost-effective and quieter in operation. However, stainless steel chains are preferred for high-temperature or extremely heavy-load applications.

Yes. Many of our plastic flat top chain series are manufactured from FDA-compliant materials, making them suitable for direct contact with food and beverages. The smooth, non-porous plastic surface resists bacteria growth and is easy to clean, meeting stringent hygiene standards in the food processing and pharmaceutical industries.

Straight-running chains, such as the 820 and 821 series, are designed for simple, point-to-point conveying in a straight line. Side-flexing chains, such as the 880, 882TAB, and 1050/1060 series, are engineered to navigate curves and turns. This allows for more complex conveyor layouts, eliminating the need for multiple drives and transfer points, and saving valuable floor space.

The 1050 and 1060 series are the only plastic flat top chains in our portfolio with a 25.4mm (1-inch) pitch, compared to the standard 38.1mm pitch of most other series. This smaller pitch provides a tighter, more compact design while maintaining heavy-duty, side-flexing capabilities. They are ideal for applications requiring high strength in a smaller footprint.

The right series depends on your specific requirements. For straight-running applications, the 820 or 821 series are excellent choices. For curved conveyors, the 880 series is the most popular option. For heavier loads or wider products, consider the 882TAB series. For applications requiring a smaller pitch with side-flexing capability, the 1050/1060 series is ideal. Our engineering team can help you select the best option based on your product characteristics, speed, and layout.

Our chains are primarily manufactured from Acetal (POM), which offers an excellent balance of strength, stiffness, and low friction. We also offer Low-Friction Acetal (LF/LFG), enhanced with PTFE or other lubricants, for ultra-low friction applications. Specialty polymers are available for applications requiring enhanced chemical resistance or specific properties.

Plastic flat top chains require minimal maintenance. Regular cleaning with water or mild detergents is usually sufficient. Inspect chains periodically for signs of wear, such as cracks or excessive elongation. Ensure proper chain tension and alignment to maximize life. Lubrication is generally not required, but in some high-speed or high-load applications, a light food-grade lubricant may be beneficial.

Yes. While plastic chains are lighter than steel, many of our series are designed for heavy-duty applications. For example, the 821 series (double hinge) and the 1963 series can handle tensile loads up to 4,000 N. For extremely heavy loads or high-temperature environments, stainless steel flat top chains may be a better choice.

To order, you will need to specify the series, width, material, and any special features (such as anti-skid surfaces). Our team can assist you in selecting the right configuration and provide a detailed quote. Contact us today to discuss your requirements.