O coração de todo sistema de pesagem

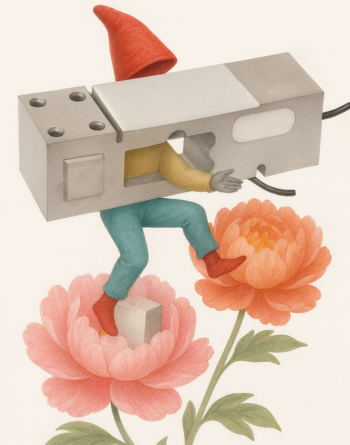

No mundo da embalagem quantitativa, a precisão é tudo. sensor de célula de carga É o componente principal que permite medições precisas em balanças multicabeçais, balanças de verificação e máquinas de envase. Ele atua como o "coração" do equipamento, um transdutor de precisão que converte a força física do peso em um sinal elétrico minúsculo e estável, fornecendo os dados fundamentais para o seu sistema de controle.

Seu sistema de pesagem está apresentando estes sinais de "problemas de saúde"?

Problema 1: Leituras de peso frequentes e instáveis

- Cada célula de carga que produzimos passa por rigorosos testes. Teste de carga excêntrica Para garantir leituras consistentes e precisas, mesmo quando o produto estiver posicionado fora do centro na balança.

- Utilizamos um sistema robusto Processo de vedação com classificação IP67, utilizando um composto de encapsulamento patenteado que bloqueia eficazmente a entrada de humidade e pó, garantindo um sinal puro e estável mesmo em ambientes húmidos ou empoeirados comuns no processamento de alimentos.

Problema 2: Diminuição da precisão ao longo do tempo (desvio do ponto zero)

- Selecionamos alta pureza liga de alumínio de grau aeronáutico para o corpo elástico, que possui propriedades antifatiga intrinsecamente superiores.

- O material passa por um processo rigoroso de múltiplas etapas. processo de tratamento térmico e envelhecimento para liberar completamente as tensões internas geradas durante a usinagem. Isso garante uma fluência mínima (≤ ±0,02% FS / 30 min) e um ponto zero extremamente estável durante o uso prolongado e de alta frequência.

Problema 3: Baixa precisão em ambientes com alta vibração

- Um layout interno otimizado de extensômetros e um design de amortecimento proprietário tornam o sensor mecanicamente insensível a vibrações de alta frequência, permitindo que ele responda apenas à força estática ou quase estática do peso do produto.

- Quando combinados com nossos transmissores digitais avançados, algoritmos de filtragem dinâmica Identifica e isola ativamente os sinais de vibração da estrutura da máquina, extraindo os dados reais de peso mesmo nos ambientes fabris mais complexos e ruidosos.

Problema 4: Danos permanentes após sobrecarga acidental

- Nossas células de carga apresentam um batente mecânico construídos diretamente em sua estrutura, fornecendo até Proteção contra sobrecarga segura 300%Isso significa que um sensor com capacidade de 5 kg pode suportar um impacto instantâneo de até 15 kg sem ser danificado.

- Essa característica de design robusto aumenta drasticamente a durabilidade e a confiabilidade do sensor em ambientes industriais reais, protegendo sua máquina e a linha de produção do seu cliente contra acidentes dispendiosos.

O que é um sensor de célula de carga?

UM sensor de célula de carga é um transdutor que converte a força ou o peso aplicado em uma saída elétrica. É o elemento central em:

- Máquinas de embalagem de alimentos

- Balanças de varejo e sistemas POS

- Equipamentos de triagem logística

- Dispositivos médicos e laboratoriais

- Sistemas de pesagem de funil e silo

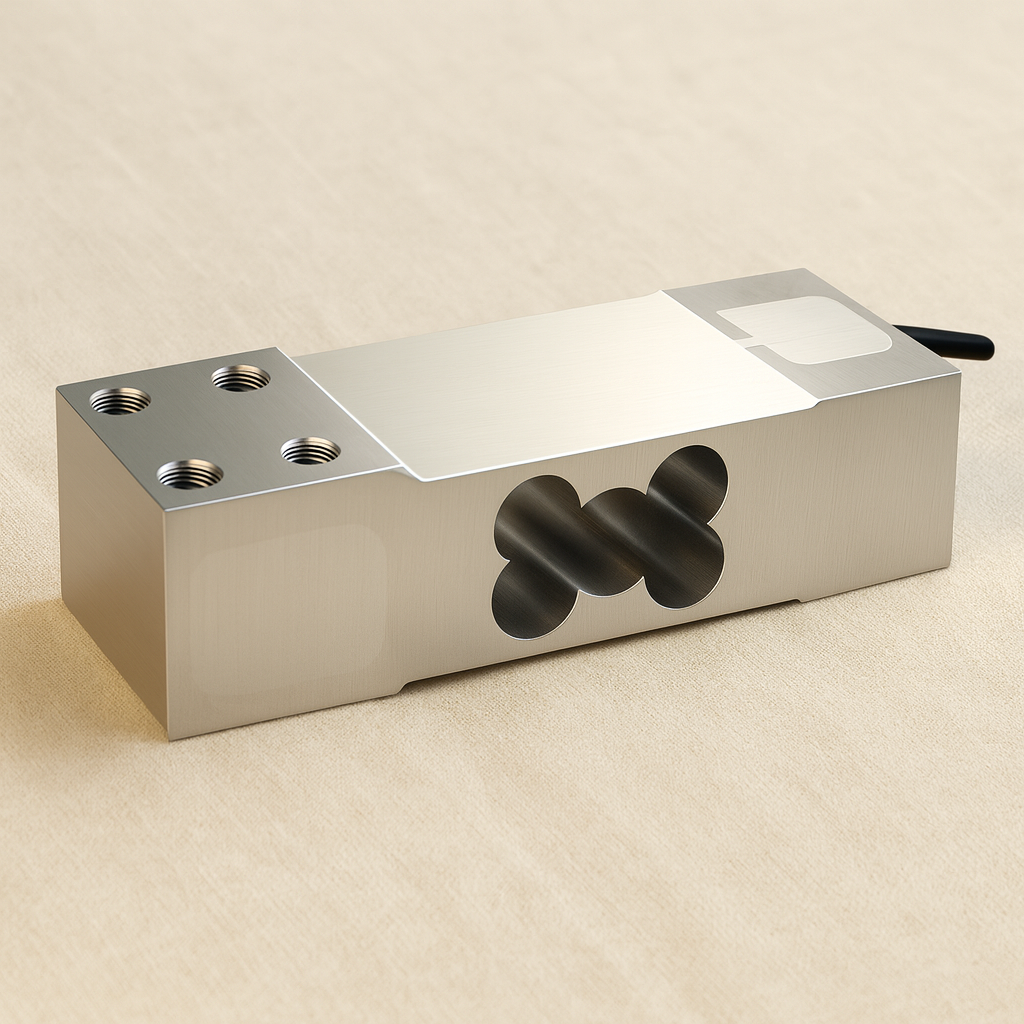

Ao combinar design compacto, construção robusta, e alta precisão, células de carga são o padrão ouro em tecnologia de pesagem.

Como funciona uma célula de carga? – Princípio de funcionamento da célula de carga

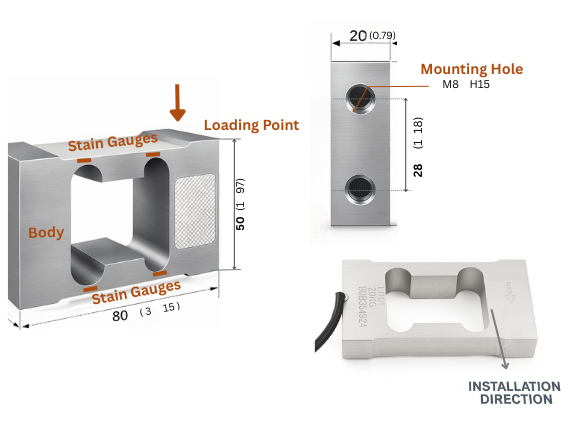

- Elemento elástico (corpo de mola): Uma peça de metal de alta qualidade, usinada com precisão (como alumínio de grau aeronáutico), que se deforma de forma leve e previsível sob uma carga aplicada.

- Medidores de tensão: Pequenos resistores em forma de folha metálica são colados à superfície do elemento elástico. À medida que o elemento se deforma, os extensômetros são esticados ou comprimidos, fazendo com que sua resistência elétrica se altere.

- Circuito da Ponte de Wheatstone: Os extensômetros são conectados a um circuito de ponte de Wheatstone. Este circuito é excepcionalmente sensível às mínimas variações de resistência dos extensômetros e as converte em um sinal de tensão diferencial.

- Sinal de saída: A tensão de saída resultante é diretamente proporcional à força ou ao peso aplicado. Esse sinal de baixo nível (normalmente em milivolts por volt, mV/V) é então enviado a um indicador de pesagem ou transmissor digital para amplificação e processamento.

Como selecionar a célula de carga correta para sua máquina

- Determine a capacidade de um único balde: Verifique as especificações de projeto da sua balança multicabeças para o peso máximo alvo de um único recipiente (por exemplo, 500 g).

- Calcular o alcance do sensor: Escolha uma capacidade nominal significativamente maior do que o peso máximo alvo do balde único. Para balanças multicabeçais, uma faixa maior proporciona melhor resolução e imunidade a ruídos. Uma regra prática comum é selecionar uma célula de carga de 5 kg para aplicações que pesam porções de até 250 g a 500 g. Não escolha um intervalo muito próximo do peso alvo.

- Confirmar dimensões físicas: Meça o espaçamento dos furos de montagem e as dimensões físicas da área de instalação desejada. Oferecemos uma variedade de tamanhos padrão da indústria para substituição direta e fácil integração ao projeto.

- Verifique o cabo e o conector: Confirme o comprimento do cabo e o tipo de conector necessários. Oferecemos opções de personalização para simplificar a fiação e o processo de montagem.

Exemplo de seleção:

- Projeto de Máquinas: Balança multicabeças de 14 posições para embalar porções de 250g de batatas fritas.

- Análise: O peso alvo por balde é de aproximadamente 250 g. Para alcançar alta precisão e imunidade às vibrações da planta, um sistema com alta resolução e estabilidade é essencial.

- Modelo recomendado: Escolha um Capacidade nominal de 5 kg Célula de carga. Isso proporciona ampla margem para lidar com forças de carga dinâmicas, enquanto sua alta sensibilidade garante a detecção precisa até mesmo das menores variações de peso, permitindo cálculos de combinação mais rápidos e precisos.

Instalação, Calibração e Resolução de Problemas

Melhores práticas para montagem de células de carga

- Utilize uma superfície estável e rígida: Monte a célula de carga em uma superfície plana, rígida e livre de vibrações.

- Limpe todas as superfícies de contato: Certifique-se de que a área de instalação esteja completamente livre de óleo, poeira ou quaisquer detritos que possam interferir no encaixe adequado.

- Aplique o torque adequado: Utilize os tamanhos de parafuso e as especificações de torque recomendados na folha de dados para evitar sobrecarregar o corpo do sensor.

- Garantir o alinhamento de níveis: A carga deve ser aplicada verticalmente. Quaisquer forças laterais ou torção afetarão severamente a precisão e poderão danificar o sensor.

- Manter autorização de segurança: Certifique-se de que não haja obstruções mecânicas (como fios ou detritos) que possam interferir na leve deflexão do sensor durante a pesagem.

Ficha de dados da célula de carga – Especificações principais

Um típico folha de dados da célula de carga inclui:

| Parâmetro | Alcance típico |

|---|---|

| Sensibilidade de saída | 1,0 – 3,0 mV/V |

| Classe de precisão | C2, C3, C4, C5 |

| Erro combinado | ≤ ±0,03% FS |

| Creep (30 min) | ≤ ±0,02% FS |

| Efeito da temperatura na sensibilidade | ≤ ±0,002% FS/10°C |

| Impedância de entrada | 350–450 Ω |

| Impedância de saída | 350–400 Ω |

| Excitação recomendada | 5–15 VCC |

| Excitação máxima | 18 VCC |

| Temperatura de operação | -30°C ~ +70°C |

| Proteção contra sobrecarga | 120–300% FS |

| Classificação de proteção | IP65 / IP67 / IP68 |

O estudo desses parâmetros garante que você selecione o célula de carga certa para sua aplicação.

Aplicações de células de carga em diversos setores

Células de carga são indispensáveis em muitos setores, incluindo:

- Máquinas de embalagem de alimentos – precisão de dosagem e enchimento

- Balanças de varejo e industriais – transações comerciais e medições industriais

- Logística e pesagem postal – triagem e faturamento automatizados

- Dispositivos médicos e laboratoriais – balanças de pacientes, balanças de diálise e balanças de laboratório

- Pesagem de funil e silo – movimentação de materiais a granel

- Plantas de dosagem e mistura – cimento, produtos químicos e farmacêuticos

Eles garantem eficiência, conformidade e qualidade do produto.

Guia rápido de solução de problemas de células de carga

- Inspeção visual: Verifique se há danos físicos (amassados, dobras), cabo danificado ou objetos estranhos presos entre a caçamba da balança e o sensor.

- Verificar a fiação: Verifique se todos os cabos estão firmemente conectados. Verifique se há umidade ou corrosão dentro das caixas de junção.

- Teste de equilíbrio zero: Com o balde vazio, faça a tara. Se a leitura não estabilizar em zero, pode haver interferência elétrica ou uma falha no sensor.

- Teste de resistência (avançado): Desconecte o sensor e use um multímetro para medir as resistências de entrada (Exc+/Exc-) e saída (Sig+/Sig-). Elas devem corresponder aos valores especificados na folha de dados (por exemplo, entrada ~380Ω, saída ~350Ω). Uma leitura de circuito aberto ou curto-circuito indica um sensor danificado.

- Dicas de montagem de células de carga – Instalação adequada para precisão

- Guia de Calibração de Células de Carga – Passo a Passo

Correto montagem de célula de carga é fundamental para garantir leituras precisas e durabilidade a longo prazo. Siga estas práticas recomendadas:

- Escolha uma superfície estável – plano, rígido e sem vibração.

- Área de instalação limpa – livre de óleo, poeira ou detritos.

- Use torque e parafusos adequados – conforme recomendações da ficha técnica.

- Garantir o alinhamento de nível – evita forças laterais que afetam a precisão.

- Evite estresses externos – cargas torcidas ou dobradas danificam os sensores.

- Siga as diretrizes de fiação – mantenha os cabos de sinal longe de linhas de alta potência.

- Manter a distância – evitar obstruções mecânicas durante a deflexão.

A instalação adequada garante durabilidade a longo prazo precisão da célula de carga e confiabilidade.

Calibração de célula de carga alinha a saída do sensor com os pesos físicos reais. O processo padrão inclui:

- Calibração zero (tara): Estabeleça uma saída de linha de base sem carga.

- Calibração de span: Aplique pesos padrão conhecidos próximos à capacidade máxima.

- Calibração multiponto: Use vários pesos para testar a linearidade.

- Verificação de carga de canto: Coloque pesos em vários pontos da plataforma.

- Teste de repetibilidade: Carregue/descarregue pesos várias vezes para garantir consistência.

Sempre use pesos de calibração certificados em condições ambientais estáveis.

Produto relacionado

Sensores de célula de carga são a base da tecnologia moderna de pesagem e medição de força. Com seus precisão, durabilidade e versatilidade, são indispensáveis em automação industrial, embalagens, dispositivos médicos e sistemas de logística. Ao compreender princípios de funcionamento da célula de carga, parâmetros da folha de dados, técnicas de instalação, métodos de calibração e manutenção, as empresas podem garantir operações precisas e eficientes.

Uma célula de carga funciona usando medidores de tensão ligado a um elemento elástico. Quando uma força ou peso é aplicado, o elemento se deforma ligeiramente, causando alterações na resistência elétrica. Essas alterações são convertidas em um sinal elétrico proporcional, representando a carga aplicada.

Precisão da célula de carga pode ser influenciado por vários fatores, incluindo não linearidade, histerese, fluência, flutuações de temperatura, interferência eletromagnética e instalação inadequada. A escolha da classe de precisão correta (C2–C5) e a calibração adequada garantem resultados confiáveis.

Calibração de célula de carga Envolve calibração zero (tara), calibração de amplitude com pesos de teste certificados e testes multipontos em toda a faixa. Isso garante que o sinal de saída corresponda à carga real aplicada. A calibração deve ser repetida periodicamente ou após modificações no sistema.

Os tipos comuns incluem:

- Células de carga de compressão – para medição de força vertical.

- Células de carga de viga de cisalhamento – usado em tanques, silos e plataformas industriais.

- Células de carga de viga S – tanto para tensão quanto para compressão.

- Células de carga de torção – medir torque.

Cada tipo é adequado para aplicações industriais específicas.

O preço das células de carga varia de acordo com a classe de precisão, capacidade, material, grau de vedação e certificação. Os modelos básicos podem custar menos de $20, enquanto os modelos de aço inoxidável de alta precisão ou hermeticamente selados podem ultrapassar várias centenas de dólares.

Com instalação, calibração e manutenção adequadas, as células de carga podem durar de 5 a 10 anos ou mais. Inspeções regulares, evitando sobrecargas e recalibração periódica prolongam a vida útil.

As células de carga são amplamente utilizadas em máquinas de embalagem de alimentos, sistemas de pesagem logística, balanças médicas, balanças de laboratório, plantas de dosagem, pesagem de funil e silo, e equipamentos de automação industrial.