Ao selecionar correias transportadoras para processamento de alimentos, é crucial entender a diferença entre correias de corrente de PVC e correias transportadoras modulares de plástico. Vamos explorar detalhadamente suas características, materiais, padrões de superfície e aplicações ideais.

🌿 Correias de corrente de PVC

Compreendendo o PVC

O PVC, ou Policloreto de Vinila, é um plástico sintético robusto, amplamente utilizado devido à sua flexibilidade, resistência a óleos e produtos químicos e durabilidade geral. É um material comum em sistemas transportadores básicos em diversos setores, incluindo o de processamento de alimentos.

Seleção de material e correia

As correias de PVC geralmente apresentam uma superfície lisa ou levemente texturizada, tornando-as adequadas para o transporte de produtos alimentícios embalados. Elas são comumente integradas a transportadores de correia simples, onde a carga é moderada e as condições são relativamente limpas e secas.

Aplicações de Correias de PVC

As correias de corrente de PVC são amplamente utilizadas em transportadores de correia horizontais padrão ou transportadores inclinados com inclinação mínima. São adequados para:

- Linhas de embalagem

- Triagem de alimentos e operações básicas de manuseio

- Processos de montagem simples

Vantagens e desvantagens

- Vantagens: Econômico, fácil de instalar, baixa manutenção.

- Desvantagens: Resistência limitada ao calor, não é ideal para condições úmidas ou que exijam muita higiene.

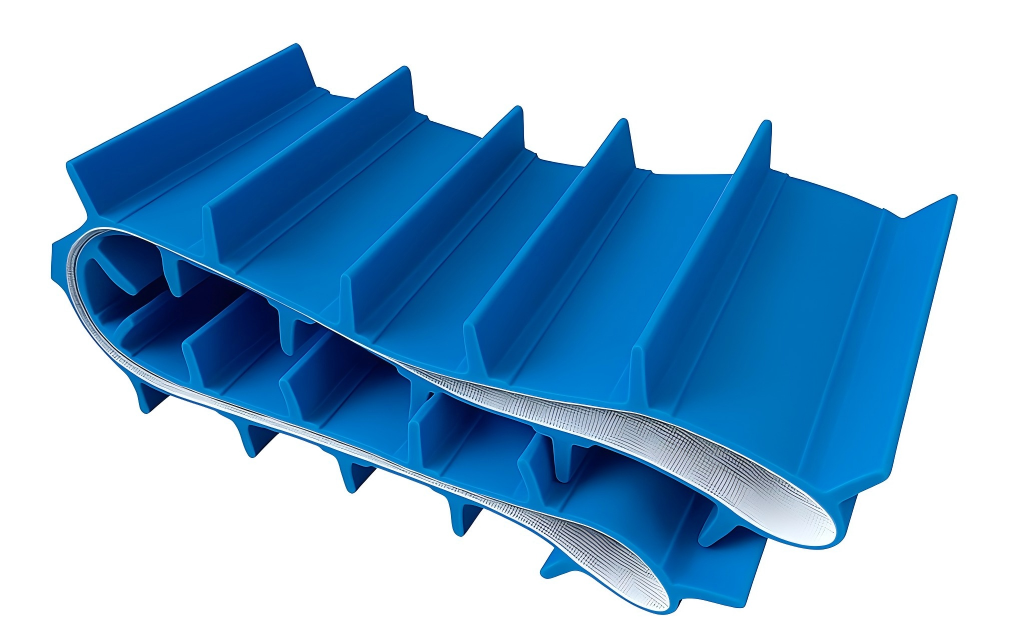

🔷 Correias Transportadoras Modulares de Plástico

Que material é usado em correias modulares?

Esteiras transportadoras modulares de plástico são feitos de segmentos plásticos interligados. Os materiais comuns incluem polietileno (PE), polipropileno (PP) e polioximetileno (POM). Cada material oferece vantagens únicas:

- PE e PP: Ideal para aplicações seguras em alimentos com excelente resistência química.

- POM: Resistência superior, durabilidade e excelente resistência ao desgaste, adequado para transportadores de alta carga ou alta velocidade.

Padrões de superfície e suas aplicações em transportadores

As correias modulares podem apresentar vários padrões de superfície, projetados especificamente para diferentes necessidades do transportador:

- Topo plano: Oferece suporte de superfície total, ideal para transporte estável de produtos em transportadores plásticos modulares padrão.

- Grade nivelada:Mais adequado para transportadores plásticos modulares que exigem drenagem ou fluxo de ar, comuns em aplicações de lavagem, secagem ou resfriamento.

- Costela levantada: Garante a estabilidade do produto, amplamente utilizado em transportadores de correia inclinados ou declinados.

- Friction Top (Antiderrapante): Ideal para transportadores plásticos modulares inclinados, lidando efetivamente com inclinações de até 20 graus, dependendo das características do produto.

- Topo de rolo: Projetado para sistemas transportadores de acumulação de baixa pressão, adequado para itens pesados que exigem manuseio cuidadoso do produto.

- Topo plano perfurado: Oferece drenagem e fluxo de ar mínimos, ideal para aplicações que exigem drenagem ou ventilação controladas.

Aplicações

As indústrias utilizam amplamente correias transportadoras modulares de plástico em sistemas transportadores complexos ou especializados, incluindo:

- Linhas de processamento de alimentos com rigorosos requisitos de higiene

- Correias transportadoras curvas, permitindo mudanças direcionais eficientes

- Transportadores de alta resistência que exigem durabilidade e manutenção mínima

- Transportadores em ambientes úmidos, de alta temperatura ou quimicamente agressivos

Vantagens e desvantagens

- Vantagens: Padrões de higiene excepcionais, limpeza fácil, layouts personalizáveis, alta durabilidade.

- Desvantagens: Custo inicial mais alto, instalação e manutenção um pouco mais complexas.

⚖️ Comparação de custos

| Tipo de correia transportadora | Nível de custo | Aplicações ideais |

|---|---|---|

| Cinto de corrente de PVC | Mais baixo | Aplicações básicas, condições secas, baixo risco de higiene |

| Correia Transportadora Modular de Plástico | Mais alto | Aplicações avançadas, altos padrões de higiene, tarefas pesadas ou especializadas |

✅ Recomendações para Seleção

- Escolha correias de corrente de PVC se sua aplicação envolver manuseio básico do produto, restrições orçamentárias e preocupações limitadas com higiene.

- Opte por correias transportadoras modulares de plástico se seus processos exigem padrões de limpeza mais elevados, higienização frequente, manuseio especializado (como curvas ou inclinações) ou maior durabilidade.

📞 Pronto para escolher sua correia transportadora ideal?

Entre em contato com nossa equipe hoje mesmo para obter consultoria especializada e soluções de transportadores personalizadas, adaptadas às suas necessidades específicas de processamento de alimentos. Vamos ajudar você a otimizar suas operações com eficiência e higiene!