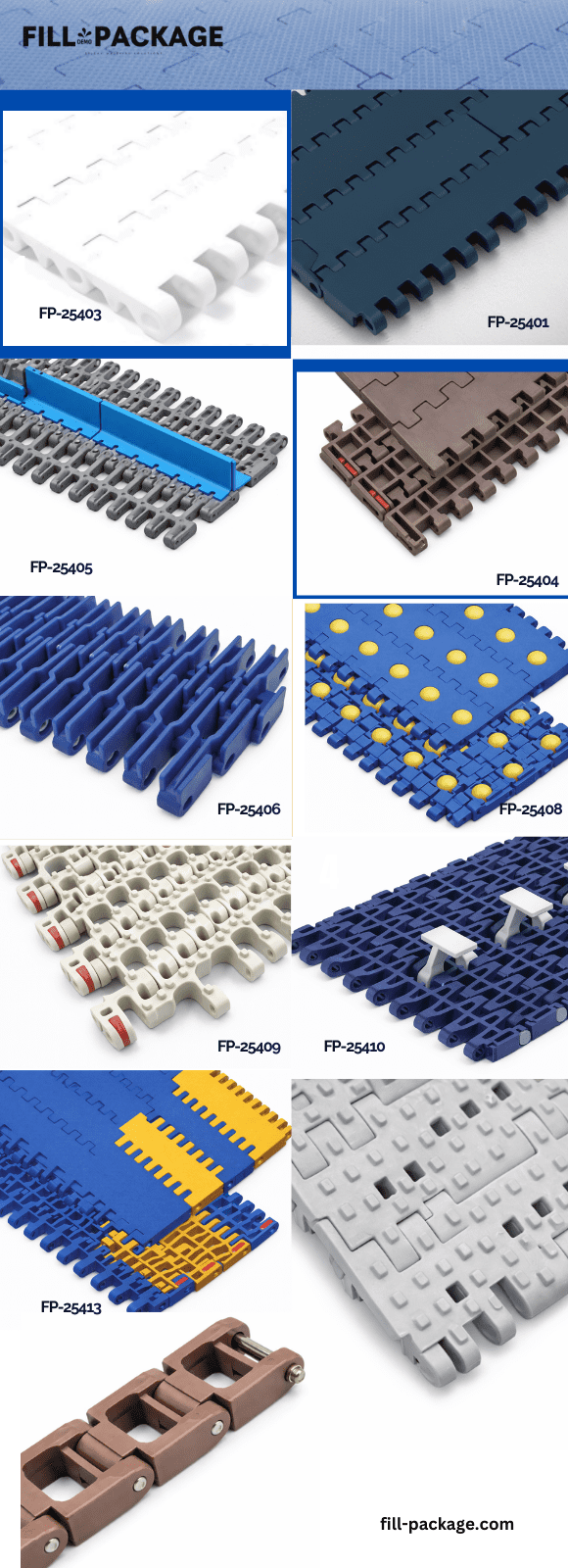

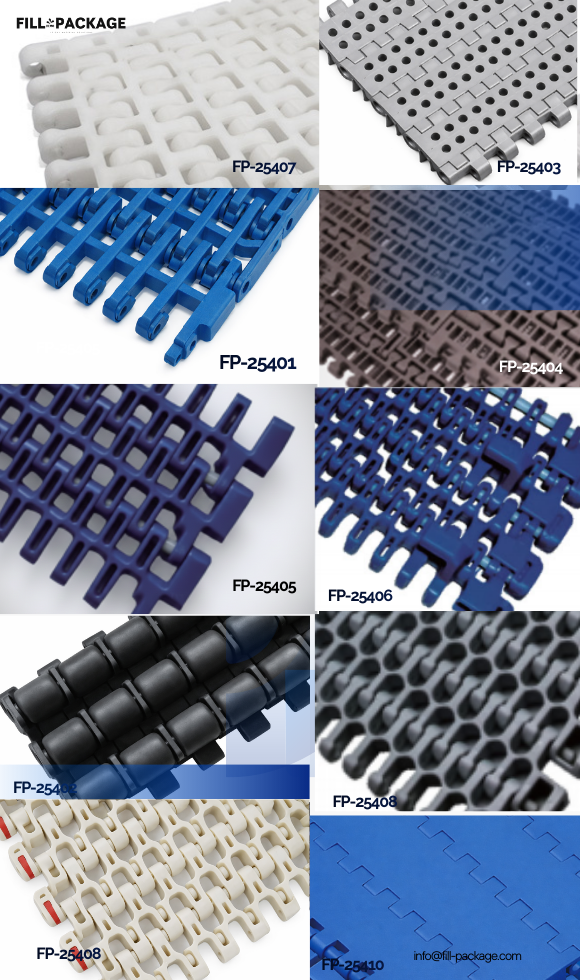

Standard Pitch Modular Belt (1-Inch Picth Series)

The definitive engineering resource for the standard pitch modular belt. This page provides an exhaustive technical overview of the 1-inch (25.4mm) series—the most versatile pitch in the industry with over 30 variants spanning nine major product families. Designed for maintenance managers, system integrators, and procurement professionals, this guide covers everything from light-duty food processing to heavy-duty logistics applications.e.

Introduction: The Universal Standard in Modular Conveying

Product Series Overview: Nine Families, Unlimited Applications

The 1-inch pitch’s unmatched versatility is demonstrated by its nine distinct product families, each engineered for specific application demands.

Light-Duty Series (FP-25403)

- FP-25403A Flat Top: Smooth surface for gentle product contact, working load up to 13,100 N/m.

- FP-25403C Circular Mesh (20% Open Area): Perforated design for drainage and airflow in food processing.

General Purpose Series (FP-25401, FP-25404)

- FP-25401 Series (7+ Variants): The most diverse family, including flat top, flat grid (40% open), circular mesh (4% open), rib mesh, and specialized lane dividers. Working loads from 400 N to 25,000 N/m depending on configuration.

- FP-25404A Flat Top: Robust general-purpose belt with 19,800-21,000 N/m capacity.

- FP-25404B Flat Grid (33% Open Area): Excellent drainage for wet processing environments.

Enhanced Grip & Drainage Series (FP-25405, FP-25408)

- FP-25405B Flat Grid: Versatile grid design with excellent support and drainage.

- FP-25405T Rib Mesh: Raised ribs provide stability and enhanced airflow.

- FP-25408T Flat Grid with Raised Dots: Textured surface for extra grip without damaging products.

- FP-25408B Flat Grid: Smooth grid for general drainage applications.

Side-Flexing & Turning Series (FP-25406, FP-25407)

- FP-25406W Turning Net Chain (56% Open Area): High open area for excellent drainage while navigating curves, working load up to 25,000 N/m.

- FP-25407W Series (Multiple Variants, 42% Open Area): Three distinct turning chain configurations for different curve radii and load requirements, working loads from 16,000 N to 32,000 N/m.

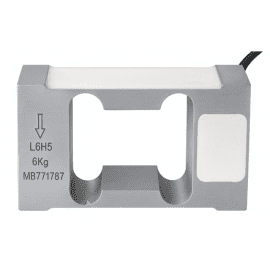

Heavy-Duty & Specialty Series (FP-25402)

- FP-25402A Rhombic Reticulated Chain: Diamond-pattern surface for maximum grip, working load up to 40,200 N/m (metal variant)—the highest in the 1-inch family.

- FP-25402Z Ball Type Mesh Chain: Integrated rollers for low-friction accumulation and sorting, working load up to 37,000 N/m.

Ultra-Heavy-Duty Logistics Series (FP-25409) – “Series 900” Equivalent

- FP-25409A Flat Top: Built for heavy carton and case transport with a POM/PA working load of 35,000 N/m—capable of supporting approximately one ton per square meter.

- FP-25409Q Ball Net Chain: Low-friction roller surface perfect for accumulation zones, sorting stations, and multi-directional movement in logistics hubs.

- FP-25409A1 Flat Top with Anti-Slip Pads: Combines high load capacity (34,000 N/m) with rubber inserts for enhanced grip on inclines and declines.

Technical Specifications: A Comparative Overview

Série | Categoria | Max. Working Load (POM) | Tipo de superfície | Open Area | Key Application |

FP-25403 | Light-Duty | 13,100 N/m | Flat Top / Circular Mesh | 0-20% | Bakery, Electronics, Delicate Products |

FP-25401 | General Purpose | 25,000 N/m | Flat Top / Grid / Rib Mesh | 0-40% | General Conveying, Food Processing |

FP-25404 | General Purpose | 21,000 N/m | Flat Top / Flat Grid | 0-33% | Packaging, Manufacturing |

FP-25405 | Enhanced Grip | 23,000 N/m | Flat Grid / Rib Mesh | Varies | Food Processing, Drainage |

FP-25408 | Enhanced Grip | 17,200 N/m | Raised Dots / Flat Grid | Varies | Inclines, Wet Environments |

FP-25406 | Side-Flexing | 25,000 N/m | Open Mesh | 56% | Curves, Spirals, Complex Layouts |

FP-25407 | Side-Flexing | 32,000 N/m | Open Mesh | 42% | Tight Curves, Alpine Systems |

FP-25402 | Heavy-Duty Specialty | 40,200 N/m | Diamond Pattern / Ball Top | 0-11% | Extreme Loads, Low-Friction |

FP-25409 | Ultra-Heavy Logistics | 35,000 N/m | Flat Top / Ball Top / Anti-Slip | Varies | Carton Transport, Logistics |

Engineering, Materials & Maintenance

Design for Unmatched Versatility

Material Selection Guide

Melhores práticas de manutenção

Produto relacionado

FAQ: Your Guide to the 1-Inch Standard

The primary difference is the distance between the hinges (the pitch). A standard pitch vs small pitch modular belt comparison comes down to application. Standard pitch (1-inch/25.4mm) is a versatile, all-purpose choice for medium-to-large products and heavier loads. Small pitch belts are used for delicate or small-footprint products that require tight transfers and minimal gaps. Our modular belt pitch selection guide recommends standard pitch for over 80% of common conveying tasks.

Use um standard pitch modular belt for the widest range of applications, including beverage canning, carton transport, general packaging lines, and even automotive assembly. If your product is stable and not exceptionally small or delicate, the 1-inch series is almost always the right starting point. With nine series families and over 30 variants, there is a standard modular belt application for nearly every need.

Yes. Our FP-25401, FP-25404, and FP-25405 series are designed as direct, dimensionally-compatible equivalents to the industry-standard “Series 400” family. Our heavy-duty FP-25409 series is a robust equivalent to the “Series 900” class, often exceeding its load-bearing capacity. Always confirm sprocket compatibility before ordering.

Start with your load requirement and product characteristics. For light products (under 10 kg), consider FP-25403. For general conveying, FP-25401 or FP-25404 are excellent starting points. If you need curves, choose FP-25406 or FP-25407. For heavy cartons or cases, the FP-25409 series is your best option. Our technical team can provide detailed when to use standard pitch modular belt guidance based on your specific needs.