In the fast-moving world of industrial automation, photoelectric sensors have become one of the most widely used and versatile detection devices. Whether it’s object detection on production lines, package tracking on conveyors, or presence sensing in safety systems, these small but powerful devices play an essential role in keeping factories efficient and products consistent.

But here comes the real challenge: with so many photoelectric sensors on the market, how to choose a photoelectric sensor that fits your exact needs? In this guide, we’ll break down the basics, explore the main types of photoelectric sensors, look at real-world applications of photoelectric sensors, discuss the disadvantages of photoelectric sensor options, and share practical tips to help you make the right choice for your business.

🌟 1. Understanding the Basics of Photoelectric Sensors

Before choosing the right photoelectric sensor, it’s important to understand how it works.

Simply put, a photoelectric sensor uses light to detect the presence or absence of objects. It consists of two main parts:

Emitter (light source): Usually infrared or visible light. It sends a beam of light in a specific direction.

Receiver (detector): Captures the light beam. If an object interrupts or reflects the light, the sensor converts this change into an electrical signal that can trigger actions, like stopping a packaging machine, starting a conveyor belt, or activating an alarm.

At the core, the technology relies on three optical principles: transmission, reflection, and diffusion. Depending on your application, you’ll need a different sensor type.

⚙️ 2. Main Types of Photoelectric Sensors

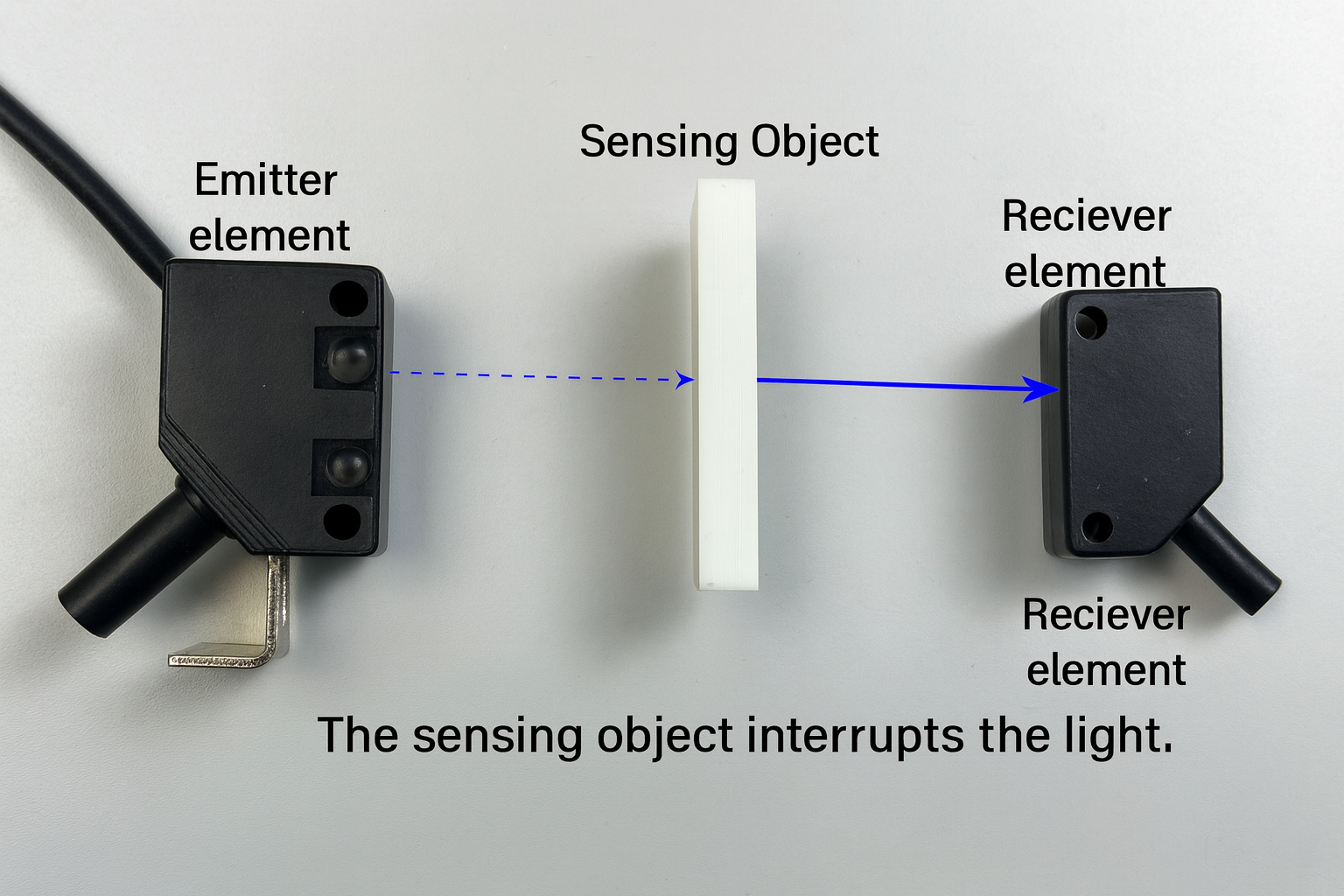

2.1 Through-Beam Photoelectric Sensor

How it works: The emitter and receiver are placed opposite each other. The light travels in a straight line. When an object passes between them and blocks the beam, the sensor is triggered.

Advantages:

- Long detection distance (up to several meters).

- Very reliable, not easily affected by color or surface texture.

- High precision positioning.

Disadvantages:

- More complex installation (requires two units to align).

- Takes up more space.

- Not ideal for transparent objects.

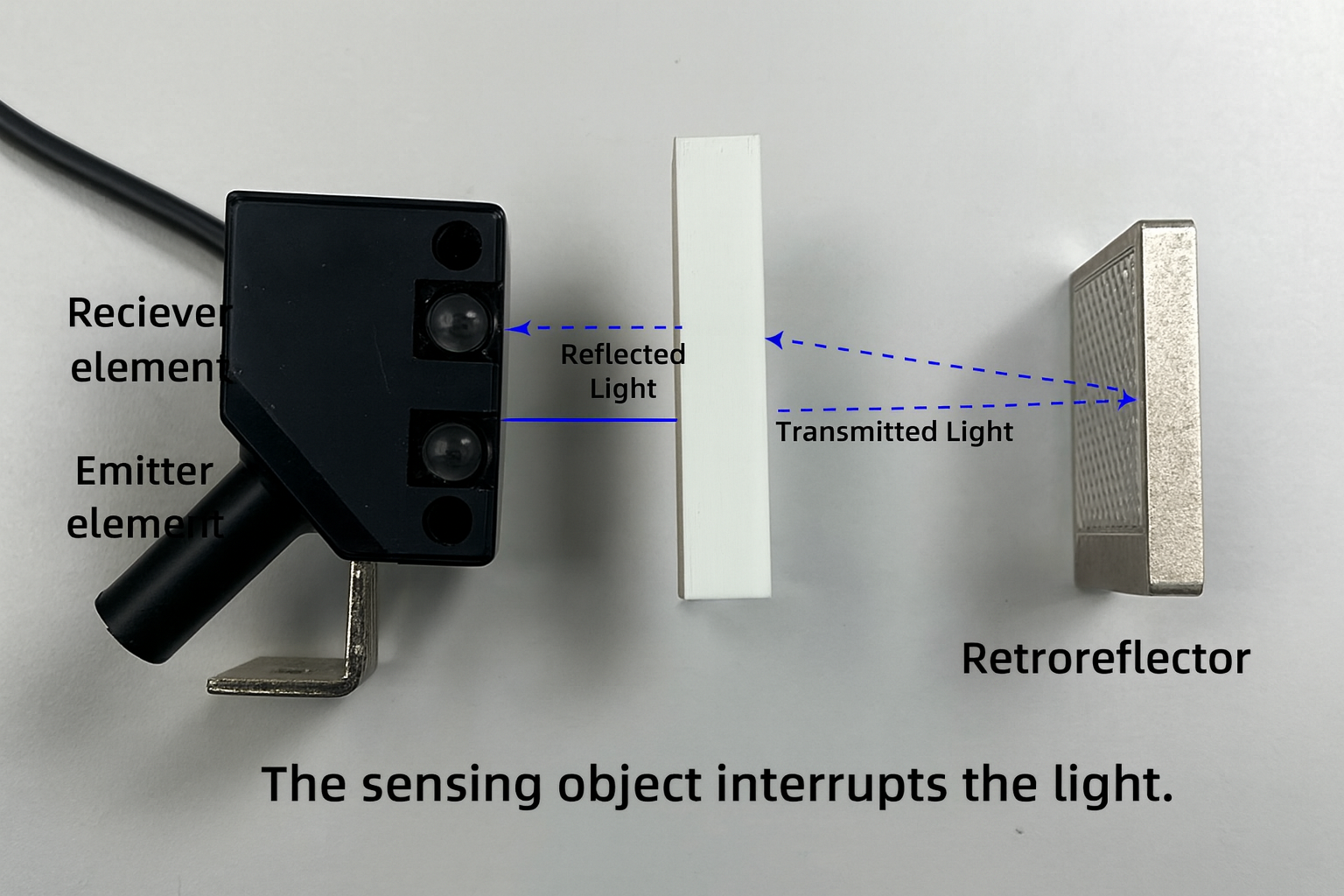

2.2 Retro-Reflective Photoelectric Sensor

How it works: Both emitter and receiver are in the same housing. A reflector is placed opposite the sensor to bounce the light back. When an object interrupts the beam, detection occurs.

Advantages:

- Easy installation (only one sensor and a reflector).

- Suitable for medium distances (a few meters).

- More affordable compared to through-beam.

Disadvantages:

- Can be affected by shiny or reflective surfaces.

- Requires a reflector, which adds a component to manage.

Tip: Use a polarized photoelectric sensor to avoid false detections from reflective packaging materials.

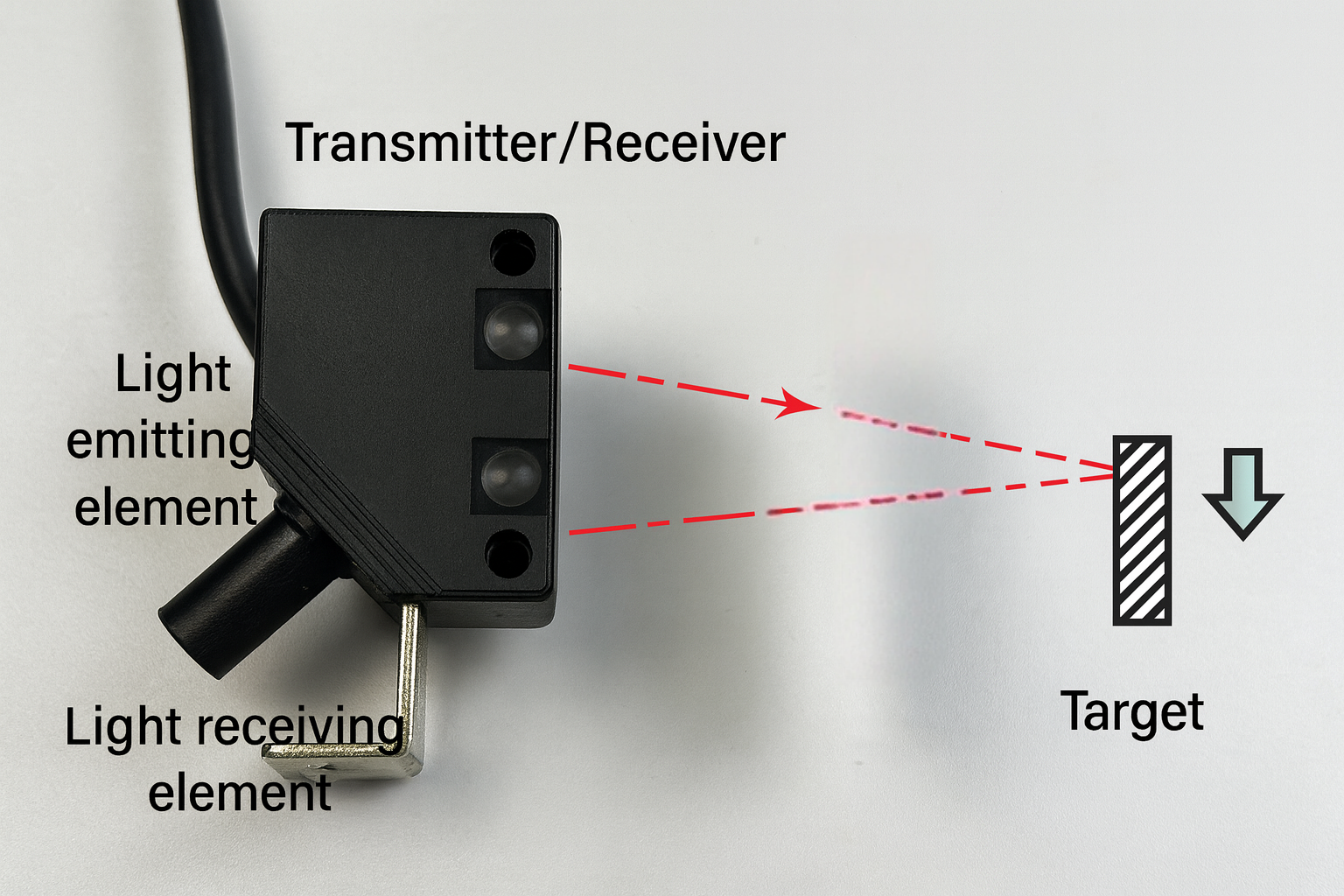

2.3 Diffuse-Reflective Photoelectric Sensor

How it works: The emitter and receiver are in the same unit. The light hits the object directly and reflects back to the sensor.

Advantages:

- Easiest to install (only one unit, no reflector).

- Lowest cost.

- Great for short-range detection and irregularly shaped items.

Disadvantages:

- Short detection distance (usually under 1 meter).

- Strongly affected by the color, surface finish, or transparency of the object.

- A photo eye sensor for conveyor with background suppression can improve reliability.

🚀 3. How to Choose a Photoelectric Sensor

When selecting the right sensor for your packaging machines or pet food processing equipment, don’t just look at the catalog specs. Consider these factors carefully:

3.1 Define Your Application

- Object type: Is it metal, plastic, paper, or food? Transparent, shiny, or matte?

- Size & shape: Small items may require high-resolution laser photoelectric sensors.

- Product properties: For sticky, oily, or fragile products, ensure the sensor is designed to handle difficult detection.

3.2 Check the Detection Distance

- Use through-beam sensors for long distances.

- Use retro-reflective sensors for medium ranges.

- Use diffuse photoelectric sensors for short-range detection or space-limited areas.

3.3 Verify Technical Specs

- Response time: Essential for high-speed packaging lines (e.g., automatic potato chips packing machine running 60–120 bags/min).

- Output type: Match PNP or NPN with your PLC.

- Light-on/Dark-on modes: Choose based on whether you want detection when the beam is blocked or when it is received.

- Excess gain: High excess gain ensures reliable detection even in dusty or humid environments.

3.4 Consider Environmental Conditions

- High humidity or washdown areas: Choose sensors with IP65 or higher protection.

- Temperature: Standard sensors may fail in freezing or high-temperature conditions; look for models designed for specific ranges.

- Packaging for chips and snacks: Since potato chips packing machines often work in oily, dusty, or humid environments, sensors with anti-condensation and anti-dust features are critical.

📦 4. Real-World Applications of Photoelectric Sensors

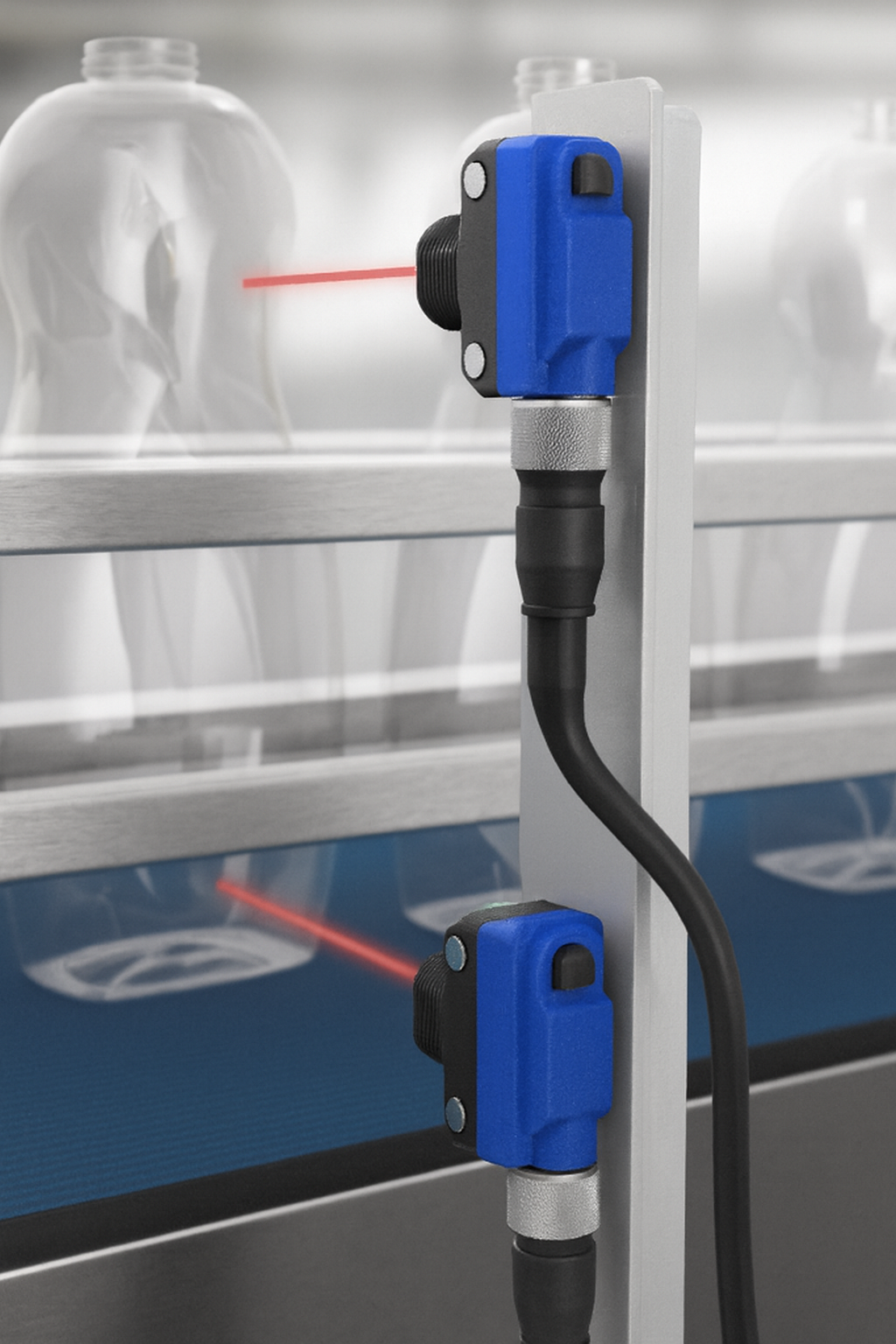

4.1 Package Tracking on Conveyors

For photo eye sensors for conveyor systems, retro-reflective sensors are often used to detect passing boxes or bags. They ensure accurate counting, sorting, and reduce human error—helping packaging machines for pet food and other industries maintain efficiency.

4.2 Level Detection in Beverage and Food Packaging

In liquid or semi-liquid food packaging machinery, photoelectric sensors check fill levels in transparent bottles or pouches. Special sensors designed for transparent object detection ensure accurate sealing and prevent product loss.

4.3 Snack and Chips Packaging

In chips packaging machines or automatic potato chips packing machines, photoelectric sensors detect product flow on conveyors, align pouches, and ensure correct sealing. For example, in packaging for chips, sensors prevent empty or overfilled packs from reaching customers—reducing waste and protecting brand reputation.

4.4 Pet Food Production Lines

For pet food packaging companies, pet food production line efficiency depends heavily on accurate detection of kibbles, treats, or pouches moving at high speeds. Reliable pet food packaging equipment with advanced photoelectric sensors ensures precise weighing, filling, and sealing while keeping products hygienic.

⚖️ 5. The Downsides: Disadvantages of Photoelectric Sensors

While powerful, photoelectric sensors also have some limitations:

- Sensitivity to surface conditions: Shiny, dark, or transparent objects can cause detection errors.

- Limited range (for diffuse type): Not suitable for long-distance detection.

- Environmental interference: Dust, oil, steam, or strong ambient light may reduce accuracy if sensors don’t have proper protective features.

The good news? Modern photoelectric sensor manufacturers are addressing these issues with innovations like background suppression, polarization filters, and IP-rated housings.

✅ 6. Practical Tips Before You Buy

- Request a detailed spec sheet: Ask suppliers to provide full information, including detection distance, response time, voltage, and IP rating.

- Test with your product: If possible, ask for a sample test on your actual product (chips, pet food, bottles, etc.).

- Check compatibility: Make sure the sensor matches your packaging machines for pet food or chips packaging machine setup, especially with conveyors and filling lines.

- Think long-term: Don’t just buy the cheapest option. Consider energy savings, durability, spare parts, and after-sales support.

🌏 7. Why Work with Professional Food Machinery Manufacturers?

Choosing the right photoelectric sensors often goes hand in hand with choosing the right equipment partner. Trusted food machinery manufacturers and food packaging companies not only supply reliable food packaging equipment but also help test and integrate sensors into your food production line.

At Fill Package, as a specialized food packaging equipment manufacturer, we design packaging lines with built-in sensor compatibility, modular conveyors, and automatic detection systems. This ensures that whether you’re running a potato chips packing machine or a full pet food packaging machine, your line runs smoothly, efficiently, and with fewer risks of downtime.

🎯 Conclusion: Smart Choices for a Smarter Factory

When it comes to how to choose a photoelectric sensor, the key is not just picking the cheapest option, but selecting the most reliable and suitable solution for your specific product and environment.

From packaging for chips to automatic potato chips packing machines and large-scale pet food production lines, the right sensor can reduce breakage, improve efficiency, ensure compliance, and boost customer satisfaction.

✨ At Fill Package, we believe that smart automation means more than machines—it means trust, transparency, and long-term value for every client.

👉 Ready to explore the best photoelectric sensors and packaging solutions for your business? Let’s talk today and design the perfect system for you.