In our fast-paced lives, every day we encounter products flawlessly packaged—from potato chips to coffee bags. Have you ever wondered how these items are packed so precisely and efficiently? Behind these everyday essentials stands an unsung hero: the Vertical Form Fill Seal (VFFS) packaging machine.

Understanding the capabilities of a VFFS packaging machine isn’t merely technical curiosity—it’s a strategic necessity for businesses in the food, pharmaceutical, and consumer goods industries. Let’s explore the secrets behind this advanced technology, its main components, workflow, applications, and how choosing the right VFFS machine can elevate your production line.

What Exactly is a VFFS Packaging Machine?

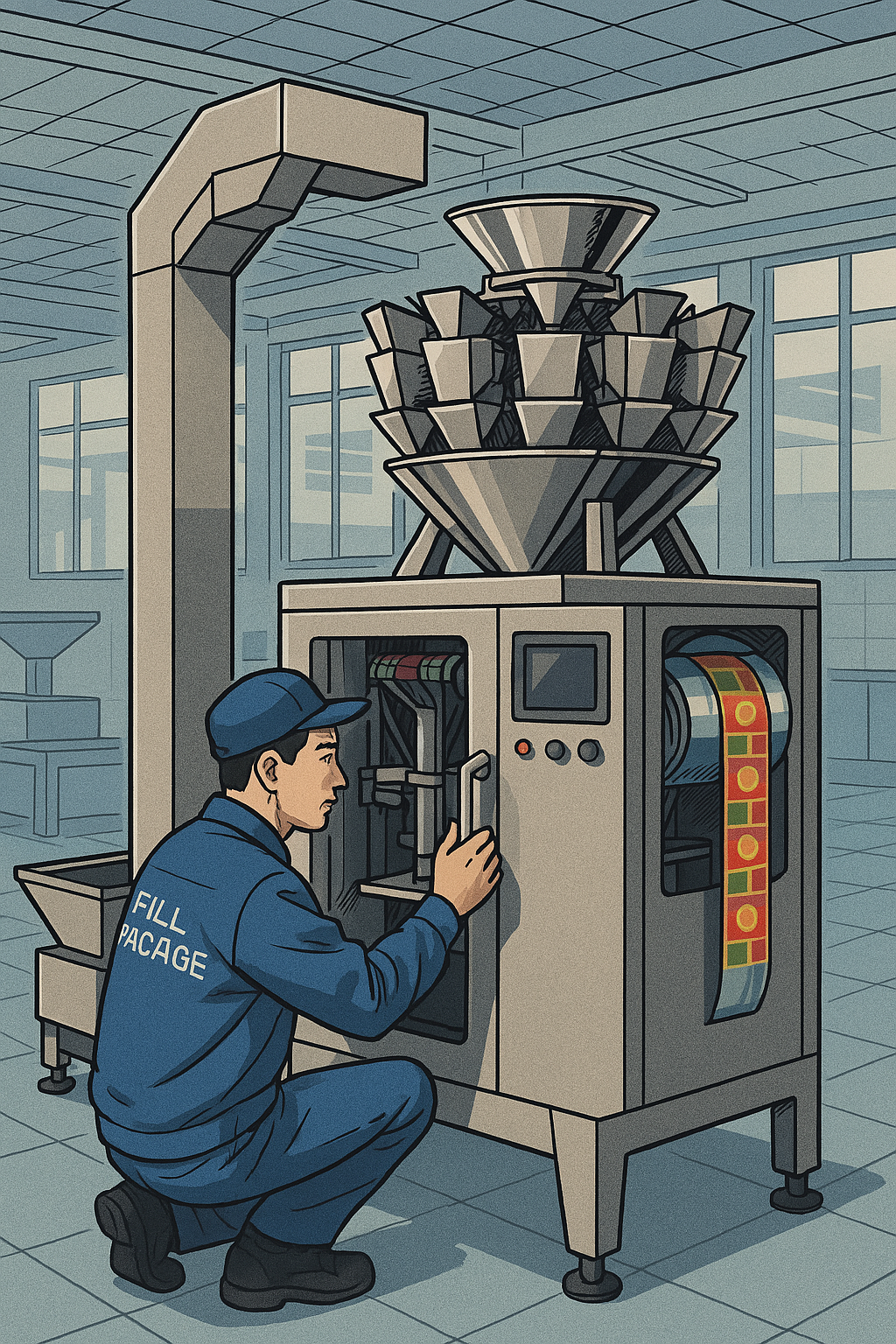

A VFFS packaging machine is a highly automated system that forms bags from flat film, precisely fills them with product, and securely seals them—all in a seamless vertical motion. Its compact, vertical operation makes it an ideal solution for efficient, space-saving packaging in various industries.

Why Choose a VFFS Packaging Machine? Key Benefits Explained

Investing in VFFS technology can bring transformative improvements to your production line:

-

High Speed & Efficiency:

Designed for continuous, high-speed production, VFFS machines produce between 30 and over 300 packages per minute, significantly boosting output and meeting fast-paced market demands. -

Remarkable Versatility:

A single VFFS machine can handle diverse products—including granular items like chips, powders like coffee, liquids, and even candies—simply by changing components. It can also produce various bag styles, such as pillow bags, gusseted bags, stand-up pouches, and three-side or four-side seal bags. -

Outstanding Cost-Effectiveness:

By forming bags directly from roll stock film, VFFS machines reduce material costs compared to pre-made bags. Additionally, automation drastically cuts labor expenses, providing excellent long-term value. -

Superior Product Protection:

VFFS machines deliver secure, airtight seals, effectively protecting products from moisture, oxygen, and contaminants. This extends shelf life, maintains freshness, and ensures product integrity throughout storage and transportation.

Inside a VFFS Machine: Key Components Explained

To grasp how a Vertical Form Fill Seal machine works, let’s break down its essential components:

-

Film Transport System:

Driven by servo-controlled belts, this system precisely unwinds flat film rolls, ensuring smooth, consistent film delivery. -

Forming Tube (or Collar):

The flat film passes around a specially shaped collar that forms it into a tube and overlaps the edges, preparing it for sealing. -

Weighing/Fill System:

Located above the forming tube, this system precisely measures and dispenses products, such as:-

Multihead Weighers for granular or solid products (chips, nuts, candies). usually :Weighing & Package Combo machine (vetfical form fill seal machine with multihead weigher )

-

Auger Fillers for powders (coffee, flour, protein powder).

-

-

-

Liquid Pumps- for sauces, liquids, and pastes. Lipuid VFFS

-

Sealing Jaws:

VFFS machines typically have two sets of sealing jaws:

-

-

-

Vertical Sealing Bars create the vertical seam.

-

Horizontal Sealing Jaws simultaneously seal the top of one bag and the bottom of the next, cutting bags accurately.

-

-

Control System (PLC):

A Programmable Logic Controller synchronizes all machine functions—from film speed and bag length to filling weight and sealing temperature—to ensure precise, efficient packaging.

VFFS Packaging Workflow: Step by Step

-

Film Unwinding:

Film is smoothly pulled from the roll. -

Forming & Vertical Sealing:

The film is shaped into a tube, and its vertical edges sealed to form a continuous sleeve. -

Bottom Seal:

Horizontal sealing jaws create a secure bottom seal for the first bag. -

Product Filling:

Product is precisely dispensed into the partially formed bag. -

Bag Advancement & Top Seal:

The film advances to the predetermined bag length. Horizontal sealing jaws close again, sealing the filled bag’s top and forming the bottom of the next bag. -

Finished Product Discharge:

Completed bags move smoothly onto conveyors or collection bins

VFFS Packaging Machine Bag Types

One of the standout features of a VFFS packaging machine is its ability to produce multiple popular and functional bag formats:

-

Pillow Bags:

The most economical and widely used style—perfect for snacks, dry goods, and daily-use items. -

Gusseted Bags:

Feature side folds to increase internal capacity. Often used for coffee beans, pet food, and products requiring more volume. -

Block Bottom (Stand-Up) Bags:

These have flat bottoms for shelf stability and a premium look, commonly found in cereals, powders, and premium food products. -

Three- or Four-Side Seal Bags:

Flat, sealed-edge pouches ideal for single-serve items like condiments, wet wipes, and small volume applications.

Choosing the Right VFFS Packaging Machine: A Quick Buyer’s Guide

When selecting your ideal Vertical Form Fill Seal machine, consider the following factors:

-

Product Characteristics:

Is it powdery, fragile, liquid, or sticky? This determines whether you’ll need a multihead weigher, auger filler, or liquid pump. -

Production Speed Needs:

Decide whether your production requires an intermittent or continuous motion machine, based on your bags-per-minute goal. -

Bag Style and Size Range:

Make sure the VFFS machine can accommodate your current packaging needs—and adapt to future ones. -

Footprint & Budget:

Assess your available space and the total cost of ownership—including purchase, installation, and maintenance. -

Supplier Reliability:

Partner with a reputable VFFS packaging machine manufacturer that provides strong technical support, training, and spare parts availability.

The Future of VFFS Packaging Machines

VFFS technology is evolving rapidly to meet growing demands for sustainability and intelligent automation:

-

Eco-Friendly Materials:

More manufacturers are switching to recyclable or compostable films. Modern VFFS machines now support sealing these materials efficiently without compromising speed or strength. -

Smart Integration (Industry 4.0):

Today’s automatic packaging machines are equipped with IoT sensors, touchscreen HMI interfaces, remote diagnostics, and even AI-powered auto-adjustment features—reducing downtime and maximizing output.

Final Thoughts: Your Partner in Packaging Excellence

A VFFS packaging machine isn’t just a piece of equipment—it’s the backbone of high-speed, high-volume packaging in modern manufacturing. Whether you’re packaging potato chips, coffee grounds, liquids, or powders, a properly configured automatic vertical form fill seal machine will deliver unmatched consistency, hygiene, and cost-efficiency.

At FILL PACKAGE, we specialize in fully customized VFFS packaging solutions tailored to your product, bag type, and production goals. Our machines are trusted by food, pharmaceutical, and consumer goods manufacturers around the world for their reliability, flexibility, and intelligent automation.

📩 Ready to boost your packaging line?

Let’s talk! Reach out today for a tailored consultation and discover how our VFFS packaging machines can help you scale production, reduce waste, and stay ahead in your market.