Check Weigher Machine

Ensure that your product weight is correct, the same as your set parameters.

Check Weigher

Check weigher is placed at the end of the production line to check whether the packaging weight of the product meets the set range. Various reasons cause weight deviation during the production ,such as the machine may leak material , or the multihead weigher may fail after a lot of work , It may also be the working environment and the foreign objects brought by the staff, all may cause the weight of the product to deviate. No matter whether the weight is small or much. neither is a good thing,When the weight is small, it will make customers dissatisfied. However, when the weight is too much, it will reduce your profit, so Check weigher will take care of the last step of your production, discover and solve problems in time.

Types Of Check Weighers

Your production quality inspector, a few popular products for your reference

Benefits In Details

Automatically reject products whose weight does not meet the parameter setting .conveyor belt speed be adjust for different speed require.

Different products are suitable for different elimination methods, which are depending on the actual situation of the product.

The whole machine is made of sanitivity stainless steel, waterproof design, easy to clean,color screen is easy to control .

Max speed :300bags/min,and Using German high-precision load cell , it can keep high precision in high-speed transmission

Checkweigher Application

The checkweigher is widely used in dynamic packaging to check whether the actual weight is same as the preset weight. When product weight is within a reasonable range, the checkweigher conveyor belt will continue to transport. On the contrary, once the checkweigher finds weigh ,beyond the preset range. It will send out an alarm and send out a signal of rejection, and automatically push out the unqualified products . The whole process does not affect the work of other equipment with fast , so it is suitable for almost all packaged products,such like : food, pharmaceutical industries. , chemical industry, daily necessities etc , if you don’t know which check weigher sutiable , please contact us and we will help you find the most suitable solution.

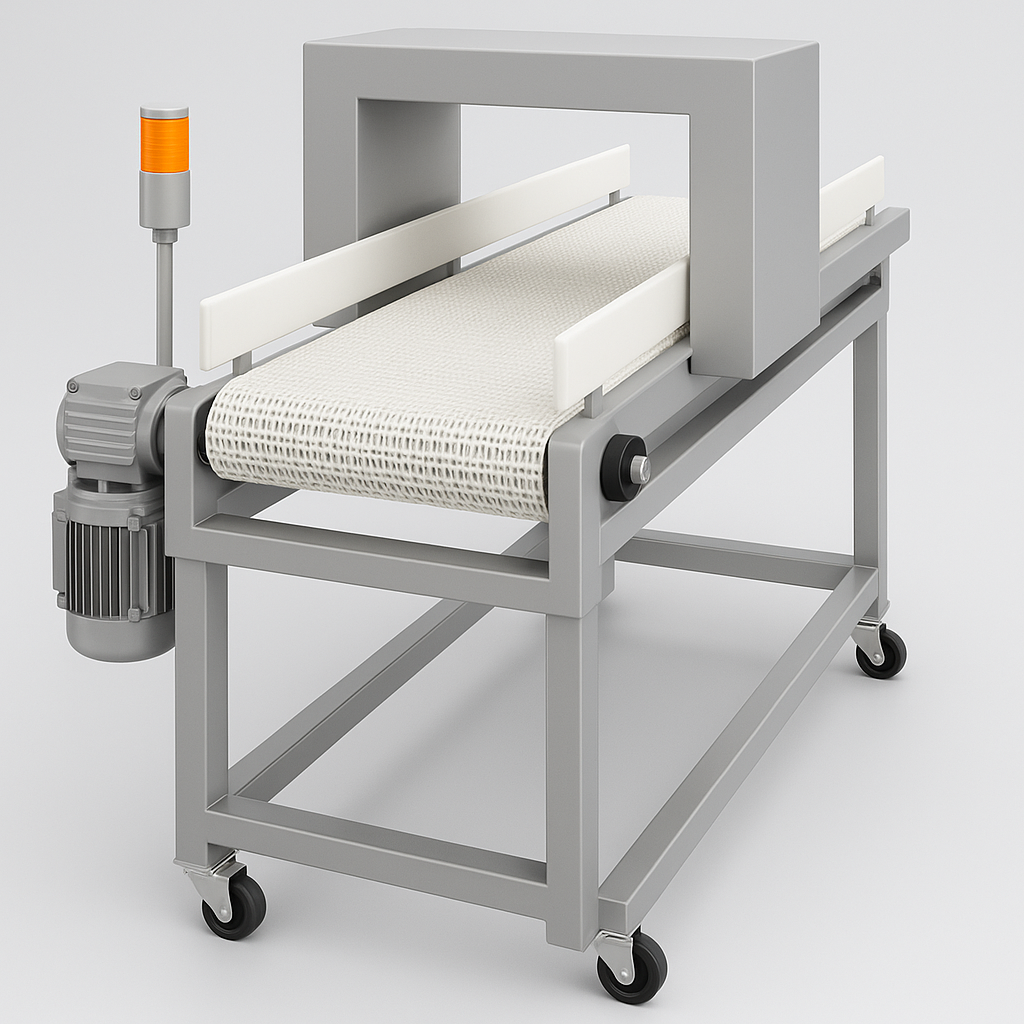

What is the Check weigher structure?

The design of the checkweigher is very compact, it plays an important role with the smallest footprint. General standard Checkweigher conveyor consists of the following parts

- Infeeding area, the conveyor will send the producst to the feeding port first

- Weighing area, the most important part of the whole machine, with high-precision load cell , it will detect whether the weight is within the appropriate range during high-speed operation.

- Rejection area, here is responsible for pushing unqualified products out of the metal conveyor conveyor , different product, the method of rejection is different . rejection option : air jet, flapper, pusher.

- The collection area, which is generally below the reject area, puts incorrect weights into the collection bucket.

Check Weigher Machine Feature

HBM high precision &Speed load cell

Danish Danfoss converter

Swiss Habbsit conveyor belt

Swiss Habas conveyor belt

American Gates Timing Belt

Japanese Oriental or German SEW motor

France Schneider Electric Components

Japanese SMC or German Festo pneumatic components

Excellent performance electronic circuits composition by FPGA LSI,low noise amplification, 24bit ADC, data lossless storage technology.

Easy operation by automatic parameter setting and intelligent product sampling.

Excellent interference proof by FPGA hardware filter with intelligent algorithms.

Better stability by ultra-fast dynamic weight tracking and automatic compensation.

Because too many factors in production affect the weight of products , it is necessary to check the quality of the weighing machine in the last step. Its benefits include:

- Save materials and increase product profits.

- Test each package of products to avoid customer complaints and penalize.and maintain your brand image.

- Fully automatic and fast completion, saving labor cost.

Our price is not low in the Chinese market, but our promise to you is that at the same price, our quality is the best, and the appearance is definitely not inferior to international brands. The important components used in the interior are all international famous brands. The performance is relatively superior, while maintaining high-speed operation, it maintains high precision, and its service life is as long as more than 10 years.

Checkweigher can customize solutions according to different standards, which are based on your specific application requirements and environment, appearance and electrical configuration, such as sensor configuration, belt size, rejection method, application in that field, etc.

Checkweigher has very good precision, high-speed transmission capability (max speed is 300BPM) and heavy capacity (more than 50kgs), and its compatibility is very strong, it can be easily integrated into the existing production line, and cooperate with other automation equipment operation, customers can easily to operate.