Horizontal flow wrap machine -SUS

- Full stainless steel machine chasis

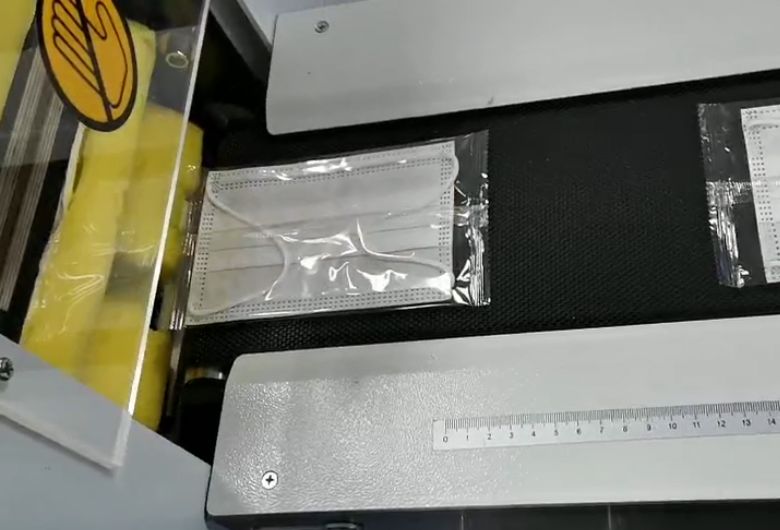

- Special for sealed small pouched with individual package

- For packaing a wide range of materials

- Cost effective automatic package line

Flow Wrapper Benefit

Horizontal flow wrap machine prevent the appearance of raw materials from being damaged and protects products from external pollution.

Good flow wrapper can keep your products fresh ,reduce the packaging volume.make products not easy to be damaged during transport and reduce the cost of transportation .at the same time .the film can be made acordinng to customer’s brand .that mean each package is a brochure .that improves the brand image .film cost is low .it can be degraded and recycled .friendly to environment .

Flow wrapper is an high efficiency and low-cost investment, especially suitable for you with high production capacity requirements. Each solution will be designed based on your products and working capacity unique, high-speed, and easy to operate.

Mini flow wrap machine -FP220S

| Model | 220 |

| Film width | Max 200mm |

| Bag length | 30-100mm |

| Bag width | 5-35mm |

| Product height | 5-60mm |

| Film roll diameter | Max 300mm |

| Packaging rate | 25-230bag/min |

| Power | 220V ,50/60Hz,3.9kw |

| Film Thickness | 25-45micron |

| Film Material | PE,OPP-PE |

How Do Wrapper Work?

Flow wrapper usually work for 3 steps .

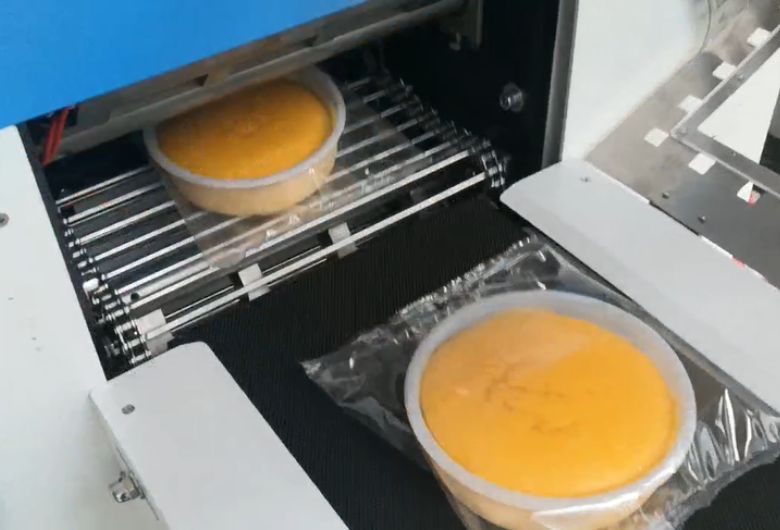

Products are fed on the conveyor

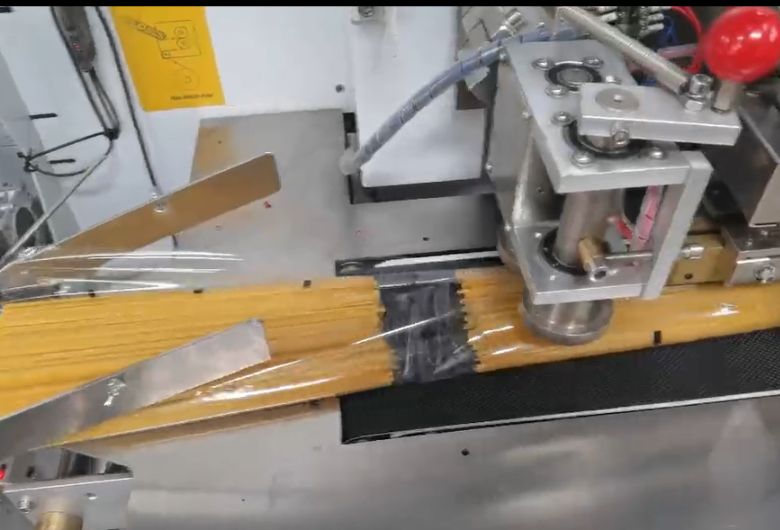

Conveyor belt delivery prouducts to sealing box .where a simple roll film wrap around products form bottom to up or form up to bottom .

Finally ,Film be sealed and cut at the end of flow wrap ,go to next package .

Usually speed always up to 70 packs a minute, depending on the speed of feeding,

How do bags look like ?

Flow wrapper bag is like a small pillow, with the upper and lower sides, and the back side. 3 sides sealing rectangular bag . design can be simple transparent ,one color or mixed color with attractive design .

What is the film made for ?

Our flow wrapper can used for variety materials.BOPP,OPP,OPP-CPP,OPP-PE,ALU-FILM-PE

PE- polyethyelene .the most commonly used packaging film ,with following advantages .which making it very popular.

- Most PE film are light and stable ,can’t be rust.

- Good impact and wear resistance ,water resistance ,moisture resistance.

- High transparency ,Good color with low cost.

- Low temperature resistant make it soft at low temperature.

- Non-toxic ,odorless and tasteless ,safety package .

Customized Design

All your flow wrappers are customized on the base of all your material situation. Mostly changes with follow points .

Film width can be customized ,standard film width rang form 200mm to 800mm ,it can be larger or smaller if you request

Material of the body have two options .carbon steel and stainless steel can be selected according to specific situation and budget .

Color and brand logo can be printed for your favorite .that make your products looks special and nice.

Customized film printing are available whatever you need simple design like one color or products code with production data or colorful brand design .it will help brand promotion much than cost .