Intro

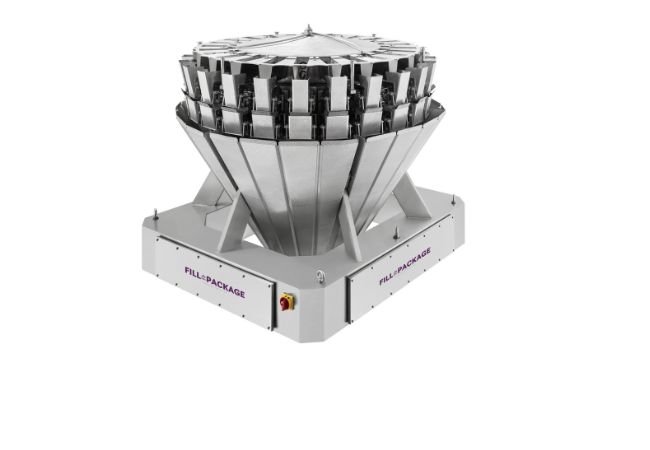

Unlike standard mixing solutions, our Mix Multihead Weighers are engineered to handle difficult-to-flow materials in multi-component blending processes.

With configurations up to 24 or 32 heads, each component is precisely fed, weighed, and combined—whether sticky, irregular, or fragile.

Through customized feeding systems, anti-stick treatments, and controlled discharge sequencing, we ensure consistent blend ratios, high accuracy, and minimal product damage.

Ideal for complex salads, marinated mixes, vegetable blends, and challenging material combinations, this solution delivers true mixing precision where vibration-only weighers fail.

Advangtages

Mixing combination scale is a combination of multiple combined scale, which is mainly used to mix a variety of different materials according to a predetermined ratio. Which has following advantages:

- Multi-material combination: it can weigh and control a variety of different materials at the same time, and can flexibly combine multiple materials according to production.

- Automatic control: It is usually equipped with an advanced automatic control system, which can automatically control the feeding amount of different materials through the preset ratio, improving production efficiency and reducing manual operation errors.

- Wide application: Mixing scales are widely used infoodchemical, building materials,and other industries to mix materials of different granule.

- Small footprint: Most of the material mixing can be done by the same scale, and different areas can work independently, saving floor space.

Why You Need This Machine

If your production involves sticky, wet, irregular, or fragile products, you’ve probably faced problems like:

- Ingredients sticking to feeders

- Uneven mixing ratios

- Product bruising or damage during weighing

- Manual correction steps that slow down your line

- Inconsistent pack weights, leading to customer complaints or giveaways

Standard multihead weighers are built for free-flowing snacks—but they fail when handling difficult-to-flow products like:

- Sticky candy (gummies, soft confections)

- Ready-to-eat meat pieces with sauces

- Fast food components that are wet or delicate

- Vegetable and seafood blends with different densities

Our Mix Multihead Weigher is not a standard machine.

It’s a customized solution, designed to blend challenging materials with accuracy, consistency, and product protection.

With this machine, you can:

- Automate complex mixing tasks

- Reduce product damage and giveaway

- Maintain brand quality and packaging precision

- Improve line efficiency without sacrificing product integrity

For difficult-to-flow product mixing, this is the solution that works.

Fast Response Aftersale Service

3 Years warranty not human damange for Main electrical parts.24/7 after-sales service support .in the same time .we are looking forward partner in different countries to open located market .we will be one team work together to give best products and service .

- Data sheet

- FAQs

- Specification

| Material | Stainless steel 304 |

| Bracket size | 0.8L,1.6L,2.5L |

| Max speed | 120 bags/min |

| Waterpoof | IP63/IP65 option |

| Accuracy | 0.3g-1g (depend on material ) |

| Control display | 12 inch color screen |

| Power supply | 220V /110V 50Hz or 60Hz option |

- Production time : Depend on QTY and machine type .usually :15-25days

- payment term : TT ,40% deposit ,60% balance before delivery .

- Sale term : Exw or FoB shunde

| Component Name | Description |

| Stepper Motor | Yanko |

| Load cell | Zemic (HBM optional ) |

| HMI controller | Kinco |

| Main Isolator | CHSO.M/Siemens (option ) |

| Circuit breaker | Schneider/Siemens (option ) |

| Leakage breaker | Schneider/Siemens (option) |

| DC power supply | Mean well |

| Intermediate relay | Omron |

| Terminal block | Weidmueller |

Focus on solutions

Mix weighers are not only ,The only thing we want to do is to make a suitable soluation according to your requirements .

Yes.

Our Mix Multihead Weigher is specially designed for difficult-to-flow materials, such as sticky candy, marinated meat, wet vegetables, and seafood.

We use customized feeding methods, anti-stick surfaces, and soft-discharge designs to ensure smooth flow and precise mixing—even for challenging products.

Each product type is controlled by its own group of weighing heads, allowing independent feeding and weighing.

Our software dynamically selects the best combination to achieve the target ratio for each material, even if their flowability is different.

This ensures consistent blends without manual adjustment.

For non-free-flowing products, speed is balanced with accuracy.

Our typical output for mixed materials ranges from 30 to 50 packs/min, depending on product complexity.

Still far more efficient and reliable than manual mixing and weighing.

No.

We pay special attention to gentle product handling:

-

Reduced drop height

-

Soft-angled chutes

-

Silicone-padded contact surfaces

These features minimize impact and protect delicate products like seafood, soft vegetables, and fragile bakery items.

No.

All contact parts are designed for quick disassembly and easy washdown.

We also apply Teflon coatings or anti-stick dimples on critical surfaces to reduce residue buildup, especially for marinated or coated ingredients.

Absolutely.

Our mix multihead weighing machine can connect to VFFS machines, pouch fillers, or tray systems.

We provide full integration drawings and adjust discharge configurations to match your layout.

Yes.

We offer product testing before production.

Send us your material samples, and we’ll provide a test video and performance report showing how the machine handles your specific blend.