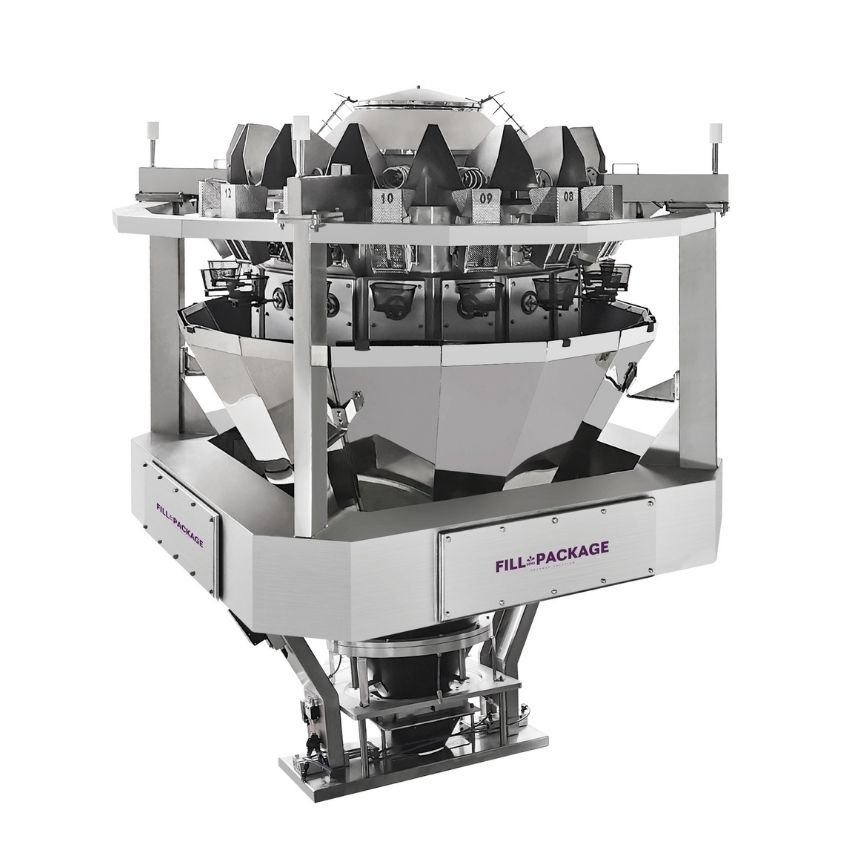

Multihead Weigher & Combination Weigher Solutions

What is a Multihead Weigher?

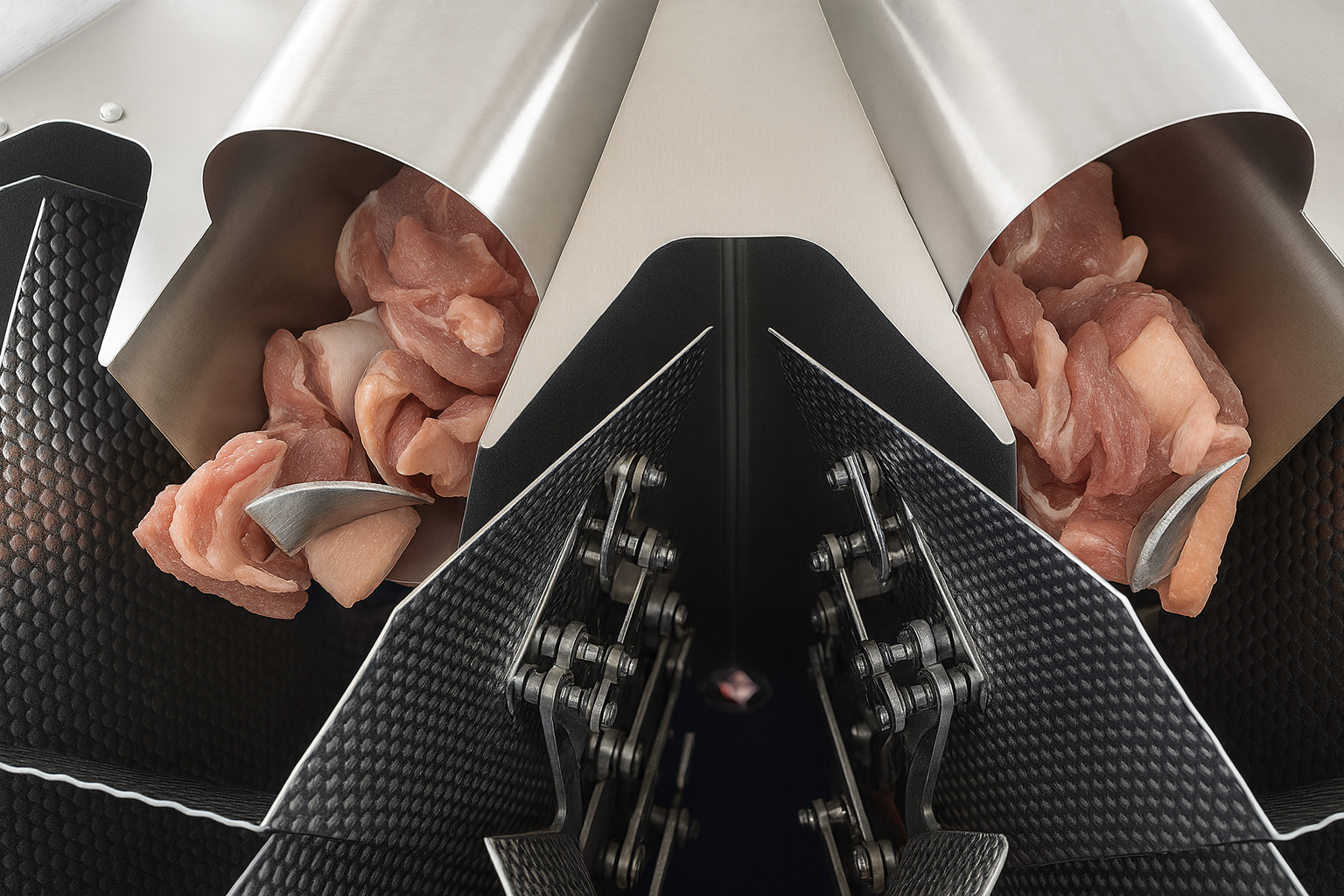

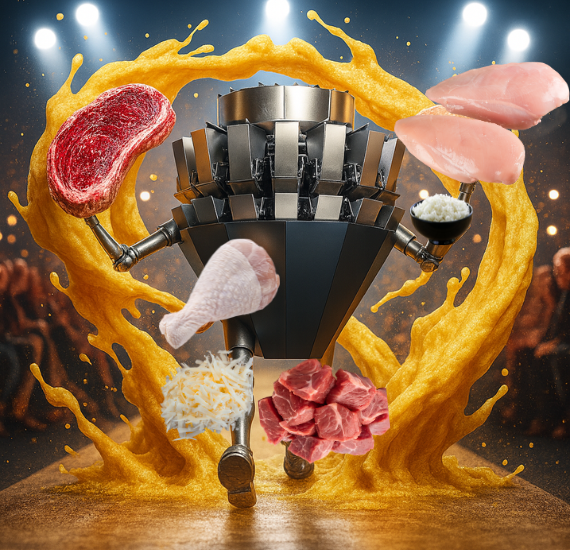

Not Just a Weigher, But a Solution for the Hardest Products

Screw Feeder Multihead Weighers

We sale more than 5000sets screw feeder Multihead weigher still now ,Our screw feeding machine has the most styles and the most stable performance. Every part of our screw feeding multihead weigher is engineered to match your product—not a catalog spec sheet. This is a made-to-fit weighing machine built around your material’s behavior.

“Patented Rolling Cup” design for weighing hopper, prevent materials sticky on it .Teflon chute with pneumatic door opening, which improve accuracy.

Screw feeding multihead weigher package machine .can handle many kinds of sticky material,such like fresh meat .fish.chicken breast.

Sticky or fragile products: Perfect for handling sticky, fragile, or irregular-shaped products that require smooth, gentle, and controlled feeding without vibration or damage.

What Makes Our Multi Weigher Systems Different?

Our systems feature main vibration pans powered by custom screw conveyors and linear feeder screws tailored in pitch, diameter, and quantity to handle your product’s unique characteristics.

Choose from single-door, dual-door, or our signature scraper-style double gates to prevent buildup and ensure a full, clean discharge every time.

Contact parts are available in flat, small dimple, or honeycomb dimple designs. We also offer Teflon-coated surfaces for superior anti-stick performance.

We tailor the chute angle, length, and design (with optional vibration or liners) for a soft drop into trays, bags, or thermoform cavities, protecting product integrity.

Multihead Weigher Working Principle

A multi head weigher, also referred to as a multi weigher or combination weigher, is a high-speed, precision weighing machine widely used for automated packaging processes. Among various types, the screw feeder multihead weigher is uniquely designed to handle sticky, fine, or hard-to-move products—while still using the same core weighing principle as traditional combination weighers.

Shared Working Principle Across All Multi Weighers

Regardless of whether it’s a standard vibratory multihead weigher or a screw feeder type, the fundamental principle remains consistent:

-

Product Feeding

Products are delivered into multiple weigh heads.-

Traditional multi weighers use vibratory feeders (main vibration pans and linear feeders) to move dry, free-flowing products.

-

The screw feeder multihead weigher, in contrast, uses rotating screw shafts to push the product forward—making it ideal for materials that do not flow well, such as sticky powders, pastes, or moist food.

-

-

Independent Weighing

Each head of the combination weigher measures a small amount of product independently. These individual weights are sent to the central processor. -

Combination Calculation

The system then calculates the best combination of heads whose total weight is closest to the target. This combination weighing method ensures minimal giveaway and consistent accuracy. -

Discharge

The selected combination of weigh buckets opens simultaneously to discharge the product into the next stage—typically a packaging machine.

Key Difference: Feeding Mechanism

While the combination weighing principle is the same across all multi head weighers, their feeding systems differ:

-

The standard combination weigher relies on vibration to move material into the weigh buckets.

-

The screw feeder combination weigher replaces vibratory feeding with screw-driven feeding, offering greater control over flow rate—especially for delicate, sticky, or semi-liquid products.

Our combination weighers are built with performance and durability in mind, using high-quality materials and components.

|

Feature

|

Specification

|

|

Material

|

Stainless steel 304

|

|

Bucket Size Options

|

0.5L, 0.8L, 1.6L, 2.5L, and 5.5L

|

|

Head Configurations

|

10, 11, 14, 20, 24 Heads

|

|

Waterproof Rating

|

IP63/IP65 optional

|

|

Weighing Accuracy

|

±0.3g to 1g (dependent on material)

|

|

Control Display

|

10.1-inch color touchscreen

|

|

Power Supply

|

220v/110v, 50Hz or 60Hz option

|

|

Preset Programs

|

Up to 100 product presets

|

|

Packaging

|

Secure wooden box for shipping

|

Why Choose Fill Package for Your Weighing Needs?

Combination Weigher Applications

|

Product Type

|

Target Weight

|

Typical Accuracy

|

Speed (packs/min)

|

|

Cooked Meat Cubes

|

250g

|

±1.5g

|

40–50

|

|

Shredded Cheese

|

100g

|

±1.0g

|

50–60

|

|

Fresh Meat

|

300g

|

±2.0g

|

45–55

|

|

Protein Powder

|

500g

|

±3.0g

|

35–45

|

|

Wet Pasta

|

200g

|

±1.8g

|

40–50

|

Fill&Package Multihead Weighers Advantage

The design and manufacture of mechanical parts can be customized according to the physical characteristics, chemical properties, shape, size and other factors of different materials. For example: powdery products need a leak-proof hopper, fragile products need a low chute and add rubber pads on the products contact surface ,large-volume salads need a heightened buffer hopper etc.

Our program can make necessary changes and customized settings according to your needs under the existing software.For example: improve the user interface, add or delete functions or modules, improving the performance and security, and so on. We are committed to providing high-quality services to ensure our customers get the best user experience.

Related Product

Let’s Be Honest…

Absolutely. Our screw feeder model is specifically designed for such applications. We customize the screw and test your actual material to ensure smooth, consistent feeding.

Yes. Our systems can store up to 100 preset programs, allowing you to switch between different product recipes quickly and easily from the control panel

Our design is simple, stable, and low-cost to maintain.

We don’t force expensive spare parts sales.

And unlike others, our PCB boards are backward-compatible, meaning no chaos managing different versions. You only need 1–2 backup boards—not a pile of SKU-matched chips.

We offer real remote support—you’ll get help even during testing, not just post-sale.

We guide you via video, parameter setup, and fault checks. If needed, we’ll repair your board rather than upsell a new one.

The frequency of calibration of combinatin scale depends on many factors, such as the accuracy of scale and accuracy your need, the environment and frequency of use, etc. In general, it is recommended that calibration scale be calibrated at least once a week. The weight of the calibration scale used also varies depending on the weighing need. The commonly used weight is 1KG. But for higher precision requirements ,calibration weighers of 100g or 300g should be used .

In addition, if you find that target weigh is different to your expectations when you use the combination scale, you should also calibrate it as soon as possible, and check whether the weighing hopper is operating normally and whether there is any material jam.

Combination scales are usually placed at the end of the production system to weigh and package the products that have been produced. It is usually placed above the weighing system or packaging system, that is, above the conveyor belt, vibrating feeder and packaging machine. At the same time, Generally, in order to ensure its stability, it will be installed on a solid working platform to avoid shaking and swaying from affecting its accuracy. In addition, in order to have better accuracy, avoid the influence of environments, such as wind and other equipment intervention .

When an unsatisfactory weight is detected, the scale will display an error message . This is to let the operator find the error in time, and immediately take out the incorrectly weighed material, so that the scale can continue to operate normally.

Add a collection hopper on the scale body can make this process automatic. It will be automatically discharged unqualified products from the other side of the collecting hopper, there is no need for the operator to solve it.

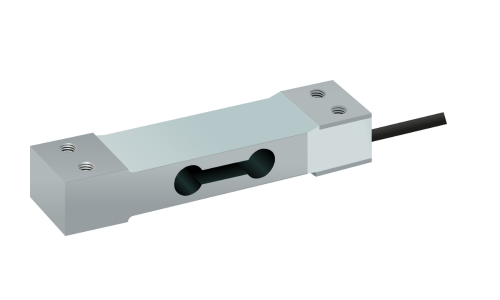

At the same time, frequent overweight will cause damage to load cell, and may lead to repair or replacement of load cell, so you should read the manual carefully before running the weighers . communicate with us in time if you have any problems during use.

Load cells are one of the most important components in combination scales. They are used to measure the weight or force of an object. They work on the principle that when an object is subjected to an external force, the material inside the object undergoes deformation, which converts the weight or force of the object into an electrical signal. By measuring these electrical signals, the weight or force of the object can be determined.

A load cell is a precision measuring parts that requires regular maintenance to maintain its accuracy and reliability, and to protect against shock ,vibration and overload

1.”Clean ” &”Zero ” all the buckets very times when start machines

2.Don’t push a large pressure on weigh buckets and load cell

3.Do switch offf the power supply when maintaining or cleaing machine .

4.Make sure machines fastern and stable .

”

”