In the rapidly evolving manufacturing sector, food packaging machines are not just tools—they are becoming strategic assets. Among them, the multihead weigher (also known as a combination weigher or multihead weighing machine) has emerged as the heart of modern weighing and packaging systems. For snacks, frozen food, confectionery, pet food, seeds, hardware, or even pharmaceuticals, the multihead weigher ensures that a packaging line operates with precision, efficiency, and profitability.

This article takes a closer look at where multihead weighing systems are heading: the rise of intelligence through AI and IoT, the pursuit of extreme efficiency and flexible production, and the non-negotiable shift toward sustainability.

1. The Current Landscape: How Multihead Weighers Work?

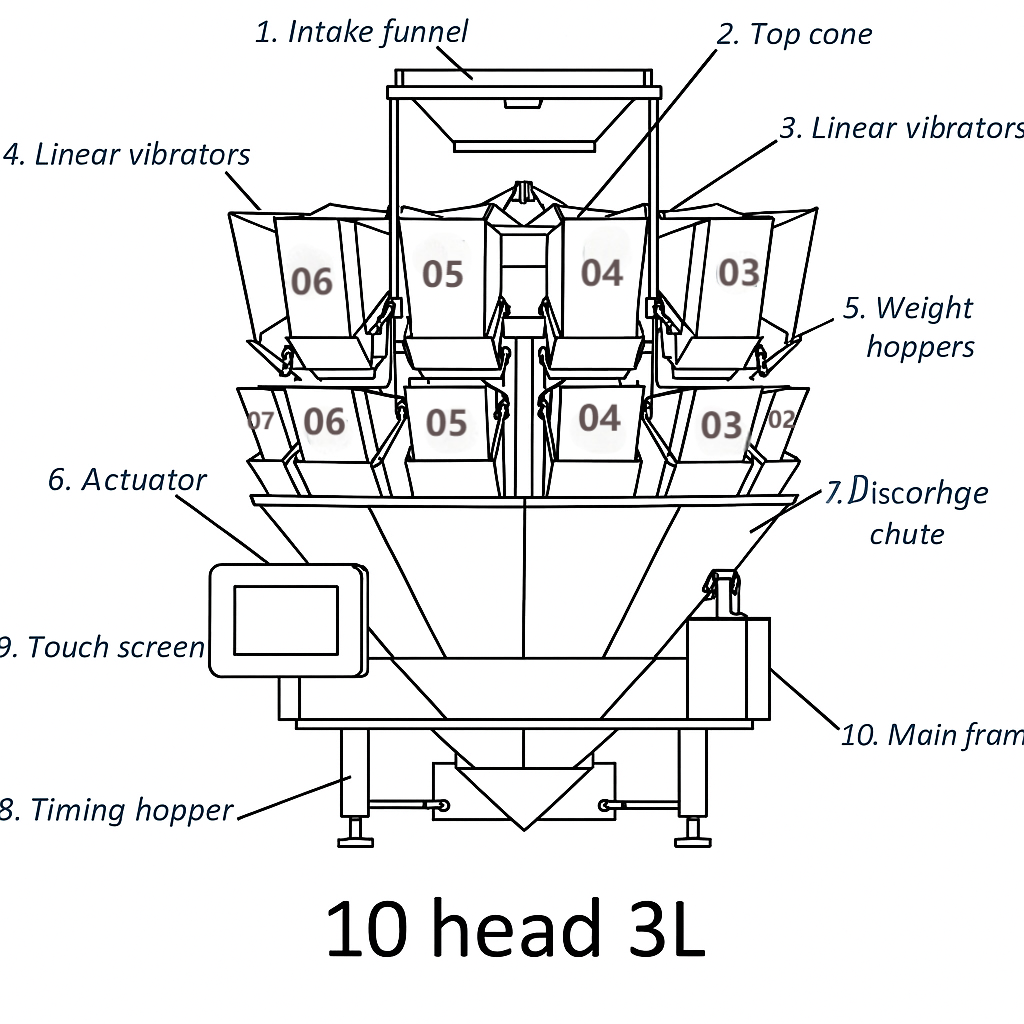

A multihead weigher operates on a deceptively simple principle: multiple weigh hoppers each measure a portion of product, and a computer selects the combination of hoppers that most closely matches the target weight. Yet behind this lies a world of advanced engineering:

- Feeding system: Belt conveyors, bowl conveyors, or bucket elevators deliver products to the top dispersion feeder. Vibratory feeders then distribute product evenly into pool hoppers.

- Precision weighing: Each weigh hopper is fitted with a load cell. Modern sensors detect even microgram deviations, enabling accuracy as tight as ±0.1–0.3 g depending on product type.

- Combination calculation: The control unit runs thousands of calculations per second, selecting the best hopper combination. Advanced processors and FPGA boards reduce latency to milliseconds.

- Discharge: Selected hoppers release product into a funnel, dropping it directly into a VFFS machine, pouch packaging machine, or flow wrapper, synchronized to avoid bottlenecks.

- Quality assurance: Downstream, metal detectors and check weighers provide an extra safety net before products reach secondary packaging, like carton sealing machines.

This system allows for high speed (up to 200+ weighments per minute), high accuracy, and adaptability to a wide range of product shapes and fragility levels.

2. Pain Points: Why Traditional Systems Struggle

Even as multihead weighers dominate modern production lines, several challenges remain:

- Slow product changeovers: Switching from, say, chips to dried fruit still requires manual parameter adjustments. Downtime costs add up.

- Data silos: Valuable production data (weights, rejects, downtime) often stays locked within the machine rather than informing the whole line.

- Reactive maintenance: Most factories rely on scheduled or post-failure repairs, risking sudden stoppages.

- Overreliance on operator experience: Optimal performance often depends on senior operators, whose knowledge is hard to transfer.

- Price wars and limited differentiation: Many manufacturers compete on cost instead of pushing innovation.

3. Trend One: Intelligence Through AI and IoT

IoT – Connecting the Line

By embedding sensors and communication modules, every piece of equipment—from multihead weighers to belt conveyors—becomes part of a connected ecosystem.

- Real-time visibility: Temperatures, vibration data, hopper weights, and cycle speeds are displayed on dashboards, enabling instant insights.

- Remote diagnostics: Engineers can log in from anywhere to troubleshoot, cutting downtime from hours to minutes.

- Data-driven optimization: IoT helps balance speeds across the line—e.g., if the multihead weigher runs faster than the flow wrapper, the system flags it automatically.

AI – Making Machines Self-Learning

Artificial intelligence brings adaptive intelligence to packaging:

- Auto-tuning: Instead of operators manually adjusting vibration frequency, AI learns product flow properties and adjusts settings automatically.

- Predictive maintenance: By analyzing vibration or motor current anomalies, AI predicts failures days in advance, enabling proactive service.

- Vision-assisted inspection: Cameras integrated above hoppers detect broken pieces, foreign objects, or clumps before weighing, ensuring only good product enters the packs.

- Smart recipe management: For nut mixes, cereals, or pet food blends, AI balances formula ratios while minimizing giveaway, saving raw materials.

4. Trend Two: Extreme Efficiency and Flexible Production

Hardware Innovations

- More heads, smarter designs: Expanding from 14 or 20 heads to 30+ with booster hoppers increases combination choices, reducing errors and boosting speed.

- Servo-driven gates: Faster, smoother discharge reduces product breakage—critical for fragile items like chips or biscuits.

- Soft-landing systems: Curved chutes, cushioned funnels, or timing belts reduce drop height and protect fragile goods.

Flexible Production

- Modular design: Quick-swap hoppers, funnels, or forming tubes allow one line to handle diverse products without major downtime.

- Automatic changeovers: Linked with robotics, the system can change films, adjust bag sizes, or swap parts in minutes instead of hours.

- Unified HMI: Touchscreen interfaces with visual guides and even AR support make adjustments intuitive, reducing training time.

5. Trend Three: Sustainability and the Green Imperative

Environmental pressure is reshaping packaging. Multihead weighers and packaging machines must adapt:

- Reducing giveaway: Each extra gram is waste. Reducing average overfill from 0.7 g to 0.3 g saves hundreds of thousands annually in raw materials.

- Energy efficiency: Servo vibration drives and energy recovery reduce power consumption. IoT energy dashboards identify inefficiencies.

- Eco-material adaptability: Machines must handle recyclable mono-material films or paper-based laminates, which require tighter sealing tolerances.

- Hygienic, easy-to-clean design: Rounded corners, IP66/69K waterproofing, and quick-disassembly reduce water and detergent use while meeting food safety standards.

6. Case Studies in Practice

- Nut mix packaging: AI-driven weighing cut raw material giveaway by 60%, saving over $100,000 annually in premium nut costs.

- Frozen dumplings: Modular conveyors plus soft-landing chutes reduced product breakage by 25%, directly improving customer satisfaction.

- Snack chips: A combination of fastback conveyors, multihead weighers, and flow wrappers enabled smoother handling, faster throughput, and better pack integrity.

7. Looking Ahead: A Smarter Packaging Ecosystem

The future is not just about better machines, but about ecosystems:

- Fully connected packaging lines where multihead weighers, VFFS machines, flow wrappers, and carton sealing machines exchange data in real time.

- Predictive scheduling that plans maintenance before breakdowns occur.

- Green packaging compatibility as a standard, not an option.

- Equipment that is not only automatic but also adaptive, intelligent, and sustainable.

Conclusion: From Automation to Intelligence

The multihead weigher packaging system is evolving into the nerve center of the packaging floor. By integrating AI, IoT, flexible hardware, and sustainable design, the industry is entering a new era of smart, efficient, and green packaging systems.

At Fill-Package, we provide not just machines but complete packaging solutions—from belt conveyors, modular conveyors, bucket elevators, multihead weighers, linear weighers, sachet counting machines, pouch packaging machines, VFFS machines, check weighers, metal detectors, flow wrappers, and carton sealing machines, to the spare parts that keep them running reliably.

👉 What do you see as the biggest challenge in upgrading your packaging line—speed, sustainability, or smart data? Leave a comment or reach out—we’d love to explore solutions together.