In today’s competitive manufacturing environment, efficiency and accuracy are essential. Automated packaging systems are now a cornerstone of modern production, and conveyor systems play a central role in making them possible. By integrating conveyors with different types of packaging machinery—including food packaging machines, VFFS packaging machines, and sachet packaging machines—companies can significantly boost productivity, reduce costs, and minimize errors.

This article explores how to design and implement conveyor-integrated automated packaging systems, covering core components, integration challenges, best practices, and a real-world case study.

Core Components of Automated Packaging Systems

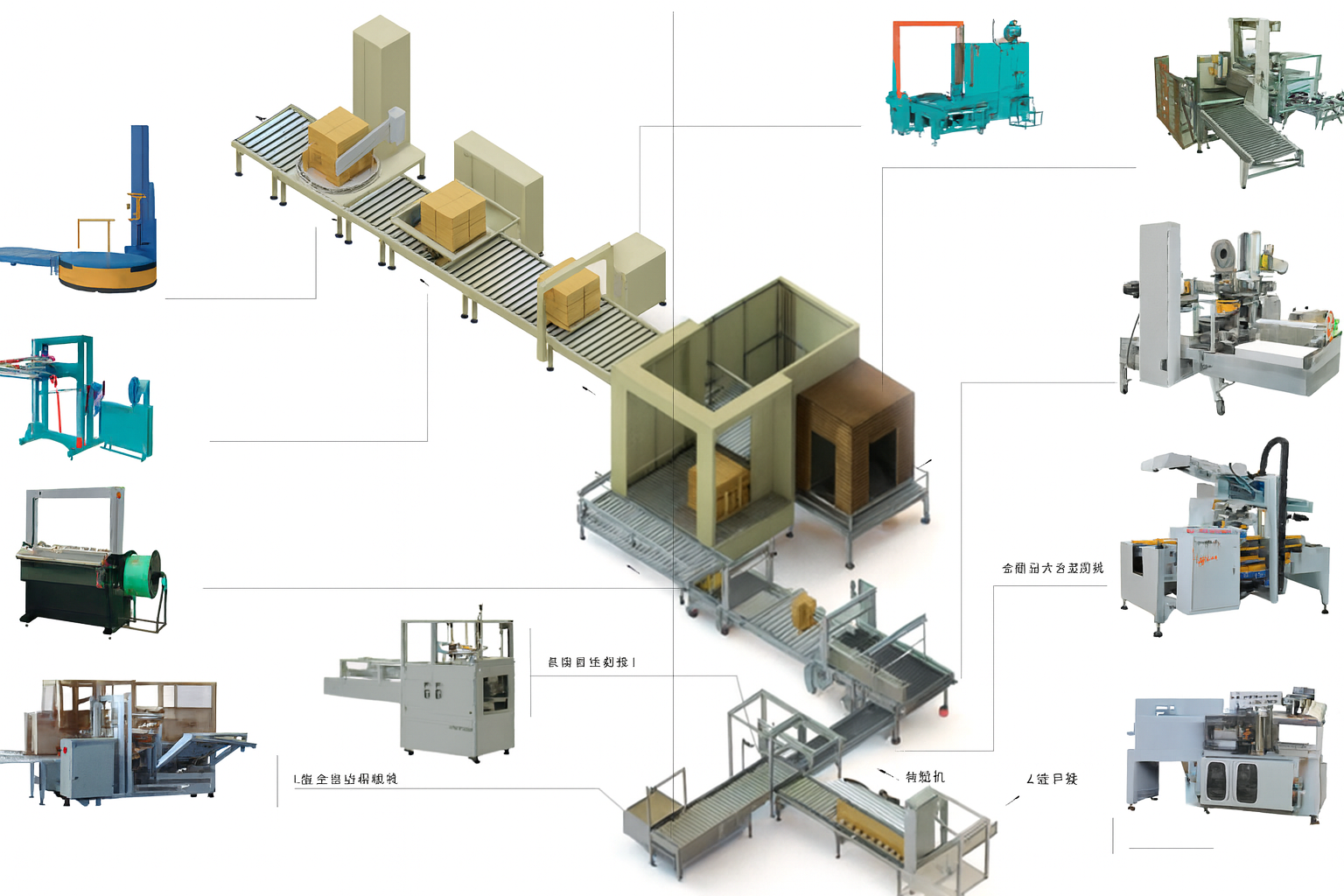

A fully integrated automated packaging system includes multiple subsystems, each performing a specific function.

1. Product Infeed and Sorting Systems

Infeed Systems: Vibratory feeders, centrifugal sorters, or robotic pickers introduce products into the line in an orderly fashion.

Vision & Sorting Systems: High-resolution cameras and software detect product orientation, shape, size, or defects, ensuring only qualified products move forward.

2. Conveyor Systems

The backbone of an automated line, conveyors transport products between stations smoothly and efficiently. Types include:

Flat Belt Conveyors – common and versatile.

Modular Plastic Belt Conveyors – easy to clean, ideal for food and pharmaceuticals.

Roller Conveyors – suited for cartons, crates, and heavier loads.

3. Packaging Execution Equipment

Cartoners / Case Packers: Place products into cartons or cases.

VFFS Packaging Machines: Form-fill-seal machines for snacks, powders, or liquids.

Sachet Packaging Machines: Ideal for single-serve products like condiments or shampoos.

Wrapping & Sealing Machines: Shrink wrap, stretch wrap, or tape sealers for secondary packaging.

4. Labeling & Coding Systems

Automatic Labeling: Applies pre-printed labels.

Inkjet/Laser Coders: Print batch codes, expiry dates, and barcodes directly on products or packaging.

5. Palletizing & End-of-Line Systems

Robotic Palletizers: Stack finished cartons onto pallets.

Stretch Wrappers: Secure pallet loads for transport.

6. Central Control System

The brain of the line, usually based on PLCs or IPCs, ensures synchronization, monitors system performance, integrates with ERP/MES, and enables traceability.

Challenges & Best Practices in Conveyor Integration

Common Challenges

Equipment Compatibility – Different OEMs may use different control protocols.

Speed Synchronization – Conveyors must match the pace of upstream and downstream equipment.

Product Stability – High-speed transport may cause shifting or damage.

Space & Layout – Poor layout design increases bottlenecks and risks.

Best Practices

Plan & Simulate: Use modeling tools to optimize layout and predict bottlenecks.

Choose Modular Systems: Select scalable conveyors and packaging equipment for flexibility.

Unified Control Standards: Use OPC UA or similar open protocols for seamless integration.

Apply Sensors & Vision: Photoelectric sensors, 3D vision, and barcode readers enhance accuracy.

Prioritize Safety: Install fencing, light curtains, and emergency stops to ensure worker safety.

Case Study: From Manual to Automated Packaging

A mid-sized cookie manufacturer transformed its packaging line with conveyor-integrated automation.

Previous Setup:

Manual tray loading, boxing, and palletizing.

High labor costs, low efficiency, frequent product damage.

Automated Solution:

Long cooling conveyors stabilized product temperature.

Robots, guided by vision systems, gently loaded cookies into trays.

Intelligent merge conveyors streamlined flow.

High-speed cartoners and sealers completed primary packaging.

Robotic palletizers stacked cartons for warehouse storage.

Results:

300% increase in throughput (30 → 120 cartons/min).

80% reduction in labor costs (20 → 4 operators).

Product quality up to 99.5% acceptance.

Full MES integration for traceability.

🧾 Bottom Line

Conveyor integration is the backbone of automated packaging systems. When combined with food packaging machines, VFFS packaging machines, sachet packaging machines, and other industrial packaging equipment, conveyor systems enable seamless, scalable, and future-proof production lines.

By adopting proper planning, modular design, and robust control systems, manufacturers can achieve higher throughput, lower costs, and improved product quality—while positioning themselves for the era of smart manufacturing.

📌 FAQs About Conveyor-Integrated Packaging Systems

Q1: Why are conveyors so important in packaging lines?

A: They connect every piece of packaging machinery, ensuring smooth product flow and consistent output.

Q2: How do conveyors integrate with VFFS or sachet machines?

A: Through PLC-based controls and unified communication standards, conveyors synchronize product infeed and discharge.

Q3: What industries use conveyor-based automation most?

A: Food, beverages, pharmaceuticals, chemicals, personal care, and agriculture.

Q4: Can conveyors work with robots?

A: Yes—3D vision systems guide robotic pickers for accurate handling even at high speeds.

Q5: Is it possible to retrofit conveyors into existing lines?

A: Yes. Modular conveyor systems are designed for scalable upgrades.

Q6: What is the ROI of automated packaging systems?

A: Most companies recover investments within 1–3 years through labor savings and efficiency gains.

Q7: Are conveyors compatible with sustainable packaging?

A: Yes. They handle biodegradable films, paper-based packs, and eco-materials.

Q8: What’s the hardest part of conveyor integration?

A: Equipment compatibility and layout optimization, best solved through simulation and standardized controls.