Introduction: A Collection of Parts is Not a Whole

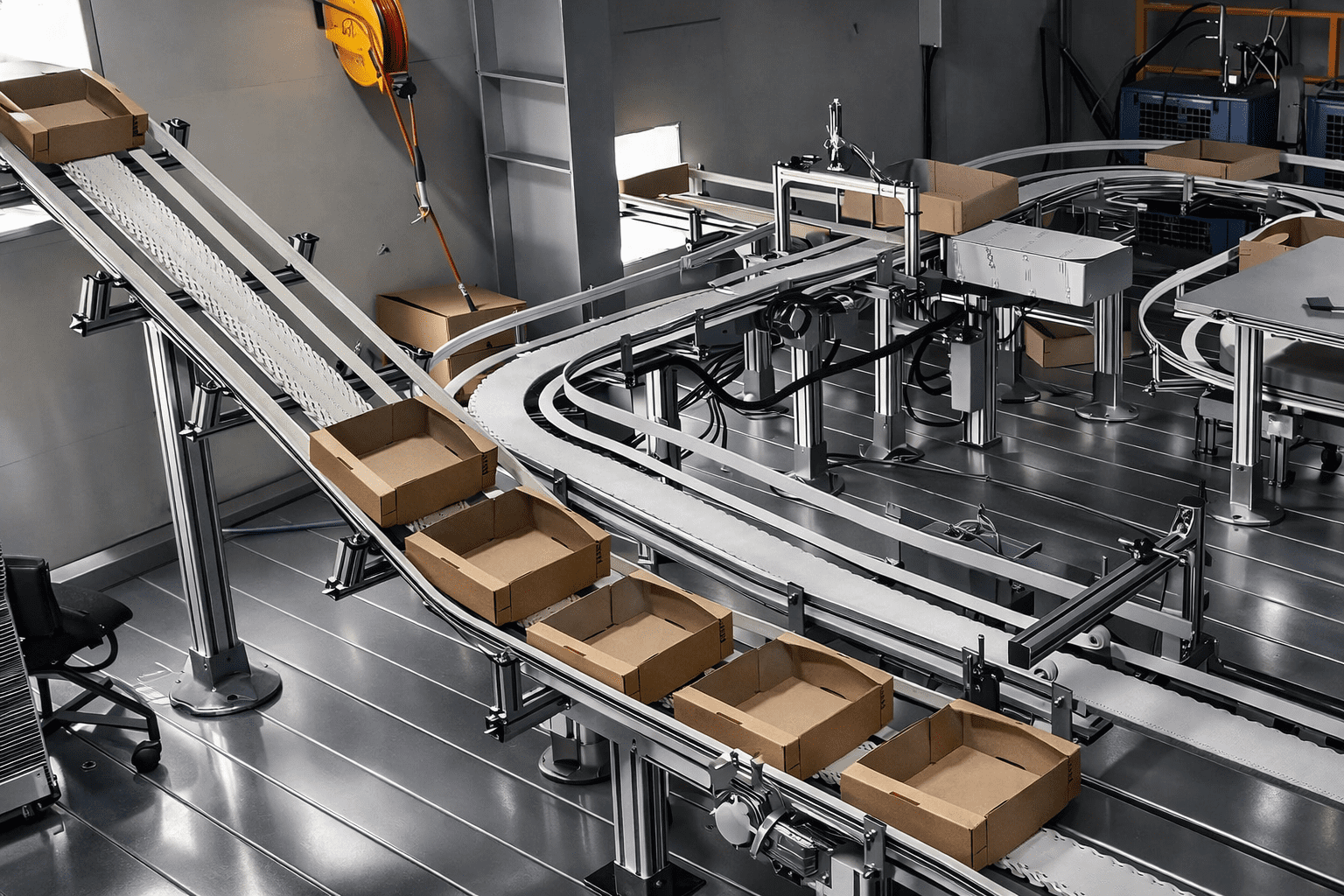

In the packaging industry, terms like “conveyor” and “conveyor system” are often used interchangeably. However, for a factory manager or a machine integrator, the difference between the two is the difference between a production line that flows smoothly and one that suffers from chronic “stop-and-go” headaches.

You can buy ten high-quality individual conveyors, connect them in a line, and still have a disastrously inefficient operation. Why?

Because an individual conveyor is hardware; A Conveyor System Is Logic.

At Fill Package, we want to help you understand why shifting your mindset from “buying belts” to “designing a system” is the key to unlocking your packaging line’s full potential.

1. The Fundamental Difference: “Move” vs. “Manage”

Individual Conveyors (The Hardware): An individual conveyor—whether it’s a flat belt, a modular belt, or an incline conveyor—has one simple job: to move product from Point A to Point B.

Characteristics: It typically has a simple On/Off switch or a fixed speed dial. It operates blindly, unaware of what the machine before it or after it is doing.

The Limitation: If the downstream machine stops, the individual conveyor keeps running, causing product pile-ups, crushing, and spillage.

Sistemas de transporte (The Logic): A conveyor system is a cohesive network of material handling equipment integrated with a central “brain” (usually a PLC).

Characteristics: It manages the flow of the product, not just the movement. It knows when to speed up, when to slow down, and when to buffer products.

The Advantage: It actively communicates with your VFFS machine, Multihead Weigher, and Case Packer to ensure the line runs at optimal efficiency (OEE).

Analogy: Buying individual conveyors is like building roads without traffic lights. Cars (products) can move, but sooner or later, there will be a traffic jam. A conveyor system provides the traffic lights, sensors, and police officers to ensure traffic keeps moving efficiently.

2. Integration: The “Handshake” Factor

The biggest technical differentiator is Conectividade.

Individual Conveyor Scenario: You buy a VFFS machine from Supplier A and a takeaway conveyor from Supplier B. They are physically placed together, but they are electrically isolated. If the VFFS machine faults, the conveyor keeps running. If the conveyor jams, the VFFS machine keeps dumping product onto the floor.

Conveyor System Scenario: A system is engineered with “Handshake” Logic.

- Upstream Interlock: The conveyor signals the Weigher: “I am running and clear. You are safe to dump product.”

- Downstream Interlock: The Case Packer signals the conveyor: “I am full/stopped. Please hold product.” This intelligent dialogue prevents waste and protects your machinery from damage.

3. Flow Control: Buffering & Accumulation

Individual conveyors operate at a constant state. Systems operate dynamically. This is crucial for handling Micro-Stops.

Every packaging line has micro-stops (e.g., film splicing, label reel changes).

Without a System: A 30-second stop at the case packer forces the entire line to stop immediately.

With a System: We design Buffering and Accumulation Zones. The system detects the downstream stop and automatically activates accumulation tables or slows down specific sections to “store” product. The upstream weigher continues running, filling the buffer. When the packer restarts, the system automatically feeds the buffered product back into the line.

Resultado: You gain minutes of extra production time every hour, which translates to thousands of dollars in revenue per year.

4. Cost Perspective: CAPEX vs. ROI

Initial Cost (CAPEX): Yes, buying 5 standalone conveyors off-the-shelf is cheaper upfront than engineering a custom integrated system.

Total Cost of Ownership: An un-integrated line requires more operators to watch for jams, generates more waste from product collisions, and suffers from lower overall throughput.

The Verdict: A conveyor system typically pays for itself within months through improved OEE (Overall Equipment Effectiveness) and reduced labor costs.

Conclusion: Stop Buying Parts, Start Building Flow

If you are building a new packaging line or upgrading an existing one, ask yourself: Do I just need to move product, or do I need to control my production flow?

At Fill Package, we don’t just sell stainless steel and motors. We provide Integrated Material Handling Solutions that act as the intelligent backbone of your factory.

[CTA Section]

Unsure if you need a simple conveyor or a full system? Let our engineers review your line requirements. We can simulate your material flow and show you exactly where an integrated system can save you money.