Frozen foods have become an integral part of modern diets—convenient, nutritious, and versatile enough to suit breakfast, lunch, dinner, and snacks. Behind the scenes, specialized frozen food packaging equipment plays a crucial role in bringing these frozen delights from production to your freezer at optimal quality.

As a trusted frozen food packaging equipment manufacturer, we’ve prepared this comprehensive guide to help you understand:

-

Frozen Food Packaging Machine Overview

-

Core Advantages of Frozen Food Packaging Equipment

-

How to Package Frozen Food: Key Technologies & Methods

-

Sustainability & Environmental Considerations

-

Applications and Markets for Frozen Food Packaging

-

Buying Tips: How to Choose the Best Frozen Food Packaging Machine

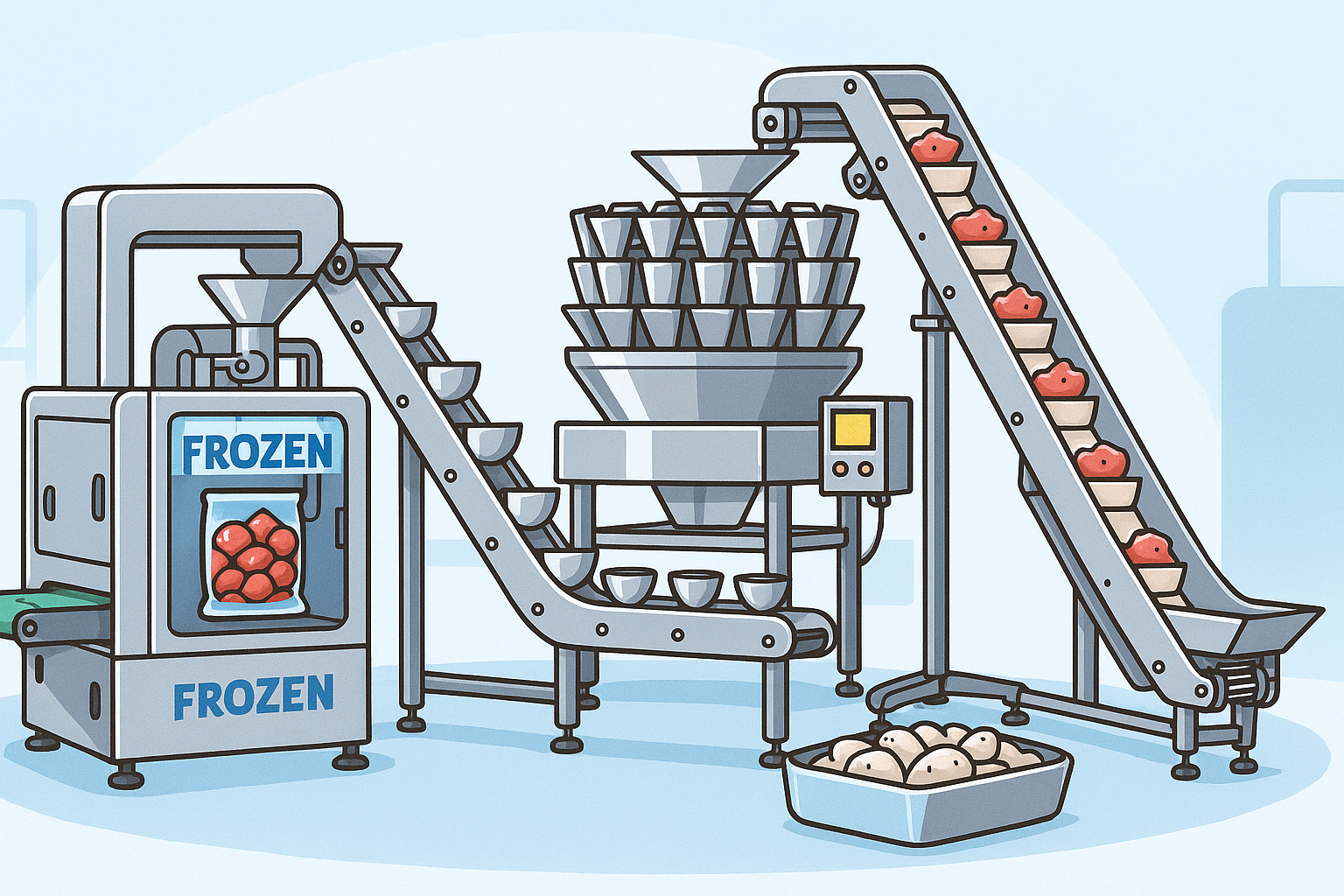

1. Frozen Food Packaging Machine Overview

Frozen foods encompass a wide variety of products, including frozen vegetables, meats, seafood, dumplings, and desserts. Packaging these products requires specialized equipment capable of handling low-temperature conditions (often as low as -40°C). The main challenges include brittleness, condensation, product sticking, and frost build-up.

A frozen food packaging machine is specifically designed to handle these challenges by optimizing:

-

Materials: Low-temperature-resistant conveyor belts (e.g., TPU or rubber) and stainless steel frames to prevent brittleness and corrosion.

-

Temperature Control: Specialized sealing equipment with heating elements and defrost systems to maintain consistent seal quality.

-

Anti-stick Treatments: Non-stick surfaces (Teflon coating, textured modular belts) to prevent food adhesion.

2. Core Advantages of Frozen Food Packaging Equipment

① Extended Shelf Life & Reduced Waste

Using advanced technologies such as vacuum packaging, modified atmosphere packaging (MAP), and nitrogen flushing, these machines protect food from oxidation and freezer burn, significantly extending product shelf life and reducing waste.

② Increased Production Efficiency

Automation minimizes manual intervention, improving efficiency, packaging consistency, and overall productivity—a crucial advantage for frozen food packaging companies facing high-volume demands.

③ Precise Weighing for Consistency

Multihead weighers precisely measure and distribute products, ensuring consistent package weights and meeting strict market regulations.

④ Versatile Packaging Options

Supporting pillow bags, stand-up pouches, zipper bags, and custom shapes, modern equipment offers various frozen food packaging ideas suitable for diverse market preferences.

3. How to Package Frozen Food: Key Technologies & Methods

Understanding the nuances of packaging frozen foods ensures maximum product integrity. Here’s how each component of a frozen food packaging line addresses common packaging challenges:

Conveyor Systems

-

Material Selection: Use stainless steel or anti-corrosive coatings for frames; belts should be cold-resistant rubber or food-grade TPU, flexible at extremely low temperatures.

-

Anti-Stick Surfaces: Incorporate non-stick (Teflon) coatings or modular belts with textured surfaces to avoid sticking.

-

Frost Prevention: Integrate heating elements along belt edges to prevent ice formation.

-

Speed & Incline: Adjust conveyor slopes and speeds based on product fragility—e.g., slower speeds for fragile items like shrimp dumplings.

Multihead Weighers

-

Waterproof & Condensation Control: Internal electronics feature heaters or desiccants to prevent moisture build-up, ensuring reliability at low temperatures.

-

Cold-Environment Calibration: Sensors and weighing modules calibrated for accuracy in sub-zero conditions (-18°C environments).

-

Fragile Product Handling: Buffering channels minimize product breakage for delicate items such as frozen berries.

Vertical Form Fill Seal (VFFS) Machines

-

Film Compatibility: Packaging films (like PE-based materials) must retain flexibility and avoid brittleness at freezing temperatures.

-

Heat-Sealing Optimization: Longer seal dwell times or higher seal temperatures compensate for surface frost or ice.

-

Defrost Functions: Intermittent defrosting devices (heated scrapers or automated cycles) keep sealing jaws ice-free. Infrared drying at product entry points removes surface frost.

-

Mechanical Adjustments: Use low-temperature lubricants (e.g., silicone-based grease), and ensure all motors and cylinders have IP65 or higher protection ratings.

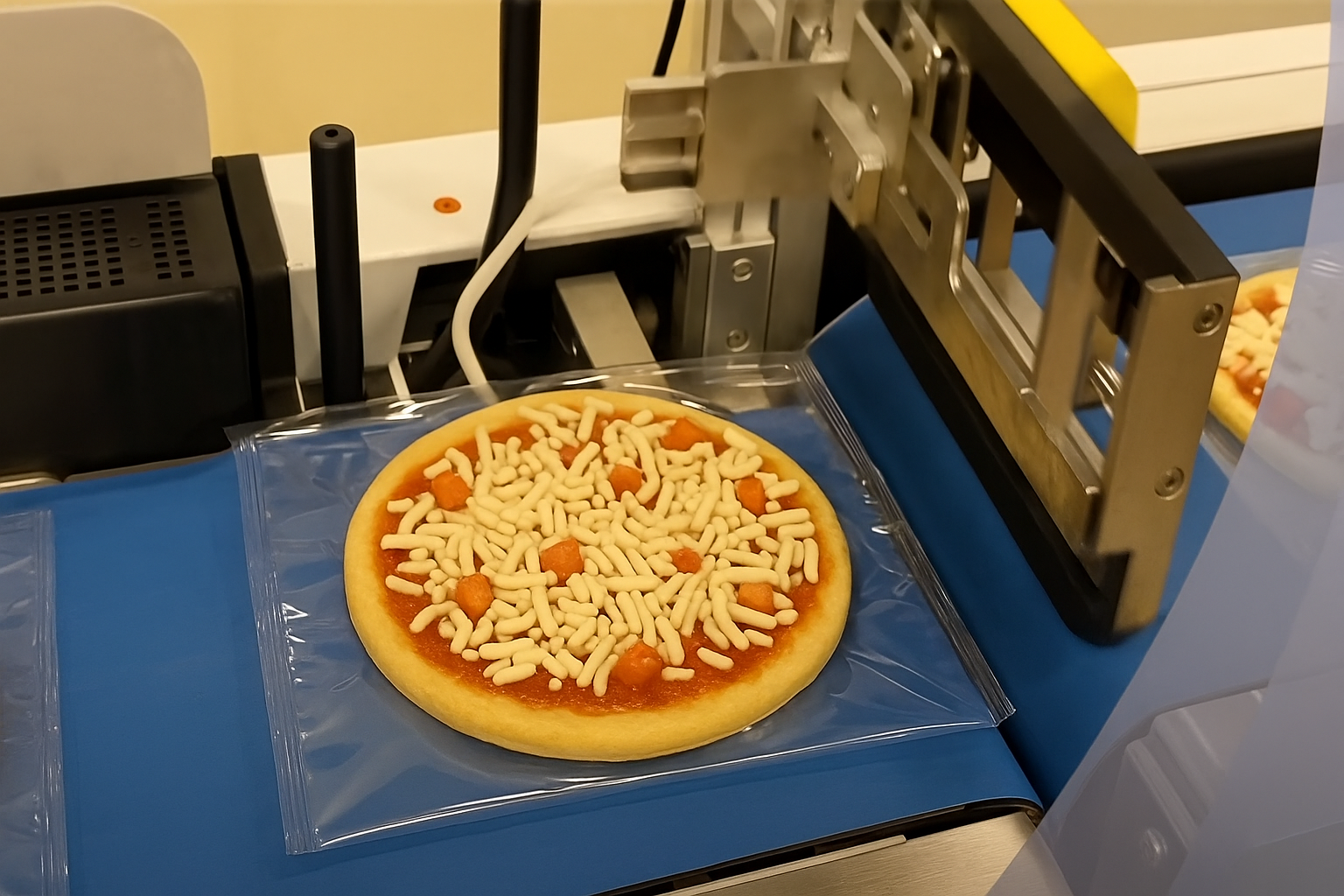

Horizontal Flow Wrappers

Ideal for packaging frozen pizzas, sandwiches, ice-cream bars—these machines offer excellent sealing and attractive finished packages.

Premade Pouch Packaging Machines

Perfect for premium frozen products (e.g., frozen fruit, chicken nuggets) and high-end markets. Suitable pouch formats include zipper bags, stand-up pouches, and specialized sport pouches.

Case Packers & Palletizers

Automate final packaging steps, efficiently packing individual packages into cartons and arranging cartons on pallets for streamlined logistics.

4. Sustainability & Environmental Considerations

Modern frozen food packaging equipment emphasizes sustainability, utilizing recyclable packaging materials and energy-efficient designs. These considerations reduce environmental impact, aligning with global sustainability trends and enhancing brand reputation.

5. Applications and Markets for Frozen Food Packaging

-

Consumer Market: Frozen vegetables, fruits, dumplings, meat cuts, seafood.

-

Foodservice & Hospitality: Frozen meals, breakfast products, appetizers.

-

Retail: Pizzas, ice-creams, ready-to-eat seafood.

6. Buying Tips: How to Choose the Best Frozen Food Packaging Machine

Selecting the right equipment from reputable frozen food packaging equipment manufacturers ensures your operations run smoothly. Consider these factors:

-

Product Characteristics: Choose machines based on product type (moisture content, fragility, shape).

-

Production Capacity: Align machine capacity with daily production volumes.

-

Factory Layout: Consider available space and height restrictions to optimize the equipment’s footprint.

-

Equipment Reliability: Select reliable suppliers known for quality equipment and excellent after-sales service.

-

Budget & ROI: Match equipment choices to budget constraints, ensuring optimal cost-efficiency.

-

Ease of Maintenance: Opt for equipment that’s easy to clean and maintain, crucial for food safety and operational efficiency.

📌 Conclusion

A well-designed frozen food packaging machine significantly enhances production efficiency, product quality, and market competitiveness. Choosing the right equipment is essential—not only to optimize your operation but also to meet the rising consumer demand for high-quality frozen food products.

Ready to explore advanced frozen food packaging ideas tailored to your needs?

Contact us today to discuss how our customized frozen food packaging equipment solutions can help your business thrive.

Pingback: viagra 100 mg