Introduction: The “Invisible” Variable in OEE

In the high-stakes world of automated packaging, engineers obsess over the speed of the Máy cân nhiều đầu and the seal integrity of the Máy VFFS. Yet, one variable is often treated as an afterthought: the conveyor belt.

Many factory managers assume that “a belt is just a belt.” They specify dimensions (Length x Width) but ignore the specific application context.

This oversight is costly. A mismatch between the belt type and the product behavior is a leading cause of jams, slippage, and hygiene failures. To achieve high OEE (Overall Equipment Effectiveness), we must stop buying generic hardware and start analyzing belt conveyor applications in packaging lines.

1. The “One-Size-Fits-All” Trap

Why does a packaging line running at 80 bags per minute suddenly jam? Often, it is because the conveyor application was not designed for the specific product transfer in packaging.

Here is what happens when the application is ignored:

Slippage: Using a standard smooth PU belt for an incline take-away application. The bag slides back, creating a pile-up at the machine discharge.

Tracking Issues: Using a friction-drive belt for a heavy-load accumulation zone. The belt stretches and wanders, damaging the edges.

Hygiene Failures: Using a fabric-ply belt for raw meat. Fluids penetrate the fabric, creating a bacterial harbor that cannot be washed out.

The Lesson: Stability comes from matching the belt material and surface texture to the specific physics of your product.

2. Critical Application Scenarios

At Fill Package, we approach conveyor application design by categorizing the specific role the conveyor plays in the system.

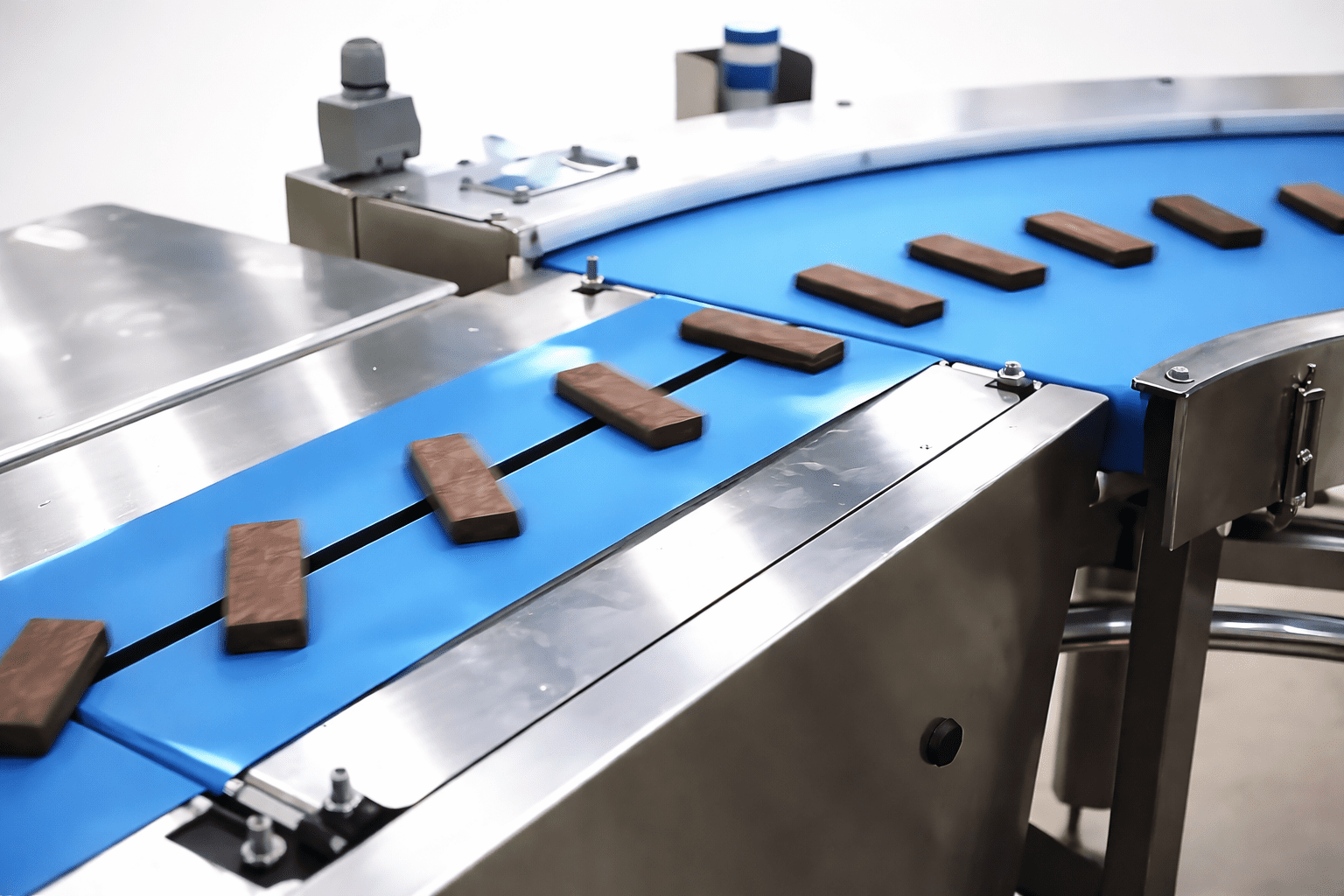

A. The Incline Discharge (Take-Away)

This is the most common application in vertical packaging. The challenge is gravity.

The Design: Chúng tôi sử dụng High-Friction Rough Top belts or Cleated (Flighted) belts.

Kết quả: Positive grip ensures the finished bag is cleared from the packaging machine instantly, preventing “double-bagging” errors.

B. The Hygiene Zone (Raw Food)

When moving raw protein or sticky vegetables to a weigher.

The Design: We implement Đai mô-đun nhựa (Positive Drive).

Kết quả: There is no tension reliance (no slippage) and the open-hinge design allows water to flush through contaminants instantly during washdown.

C. The Transfer & Handshake

Moving product from a check-weigher to a metal detector.

The Design: Chúng tôi sử dụng Knife-Edge (Nose Bar) transfers with tight tolerances.

Kết quả: Even small packs transfer smoothly without getting stuck in the gap, maintaining perfect packaging line stability.

3. Why Application Design Saves Money

Investing in the correct application-specific conveyor costs slightly more upfront than a generic “off-the-shelf” unit, but the ROI is immediate.

Reduced Waste: No more damaged products from falls or jams.

Faster Changeovers: Modular belts can be repaired in minutes by snapping in a new link, rather than hours of vulcanizing a flat belt.

Consistent Flow: Correct friction coefficients ensure the weigher receives a steady stream of product, optimizing its accuracy.

Conclusion: Engineer the Flow, Don’t Just Buy a Belt

The difference between a line that runs smoothly and one that constantly stops lies in the details of belt conveyor applications in packaging lines.

Don’t guess which belt works. Let us analyze your product—whether it’s frozen, hot, oily, or fragile—and engineer the perfect transfer solution.

Struggling with belt tracking or slippage? It might be the wrong application. Check out our specialized belt conveyor solutions designed for the food industry.