Để cung cấp cho bạn một cái nhìn tổng quan toàn diện về chúng tôi hệ thống chất lượng mạnh mẽChúng tôi sẽ trình bày loạt bài viết gồm 9 phần trên blog. Chúng tôi tin rằng loạt bài này sẽ cung cấp những hiểu biết giá trị về quy trình đảm bảo sự xuất sắc của chúng tôi.

Tại sao vật liệu lại quan trọng trong máy đóng gói thực phẩm

Trong thế giới của máy đóng gói thực phẩm-từ băng tải ĐẾN máy đóng gói túi—việc lựa chọn vật liệu ảnh hưởng trực tiếp đến độ bền, vệ sinh và hiệu suất tổng thể. Đối với các ngành công nghiệp như chế biến thức ăn cho thú cưng, nơi mà sự an toàn và tính nhất quán là yếu tố quan trọng, thép không gỉ thường là lựa chọn hàng đầu. Nhưng không phải tất cả thép không gỉ đều giống nhau. Trong số những loại được sử dụng phổ biến nhất là thép không gỉ 304 Và thép không gỉ 201. Biết được sự khác biệt giữa chúng sẽ giúp bạn đầu tư thông minh hơn.

Thép không gỉ 304 so với 201: So sánh chính

1. Khả năng chống ăn mòn

- Thép không gỉ 304: Khả năng chống gỉ và ăn mòn tuyệt vời. Lý tưởng cho môi trường ẩm ướt, dầu mỡ và thậm chí cả axit nhẹ - những điều kiện thường thấy trong dây chuyền sản xuất thức ăn cho vật nuôi và thực phẩm nói chung.

- Thép không gỉ 201: Hàm lượng niken thấp hơn, thay thế bằng mangan và nitơ. Giá cả phải chăng hơn nhưng khả năng chống ăn mòn kém hơn, đặc biệt là trong môi trường ẩm ướt hoặc mặn.

👉 Mẹo: Nếu dây chuyền đóng gói của bạn liên quan đến thực phẩm đông lạnh hoặc có độ ẩm cao như thức ăn cho thú cưng, hải sản hoặc nước sốt, thì thép không gỉ 304 là lựa chọn an toàn hơn để có độ bền lâu dài.

Thử nghiệm phun muối

2. Độ bền và sức mạnh

- 304: Mạnh mẽ, độ bền cao và chống nứt, làm cho nó trở nên hoàn hảo cho hệ thống băng tải, thang máy xô, Và khung bao bọc dòng chảy chạy liên tục.

- 201: Cứng hơn nhưng giòn hơn, có thể dẫn đến mài mòn nhanh hơn trong các ứng dụng có tải trọng cao hoặc ma sát cao.

👉 Mẹo: Vì máy cân nhiều đầu, máy cân tuyến tính, hoặc máy đóng gói túiThép không gỉ 304 mang lại độ ổn định tốt hơn và tuổi thọ dài hơn.

3. Hiệu quả về chi phí

- Thép không gỉ 201: Giá cả phải chăng hơn, phù hợp với các dự án tiết kiệm chi phí hoặc môi trường ít tiếp xúc với độ ẩm.

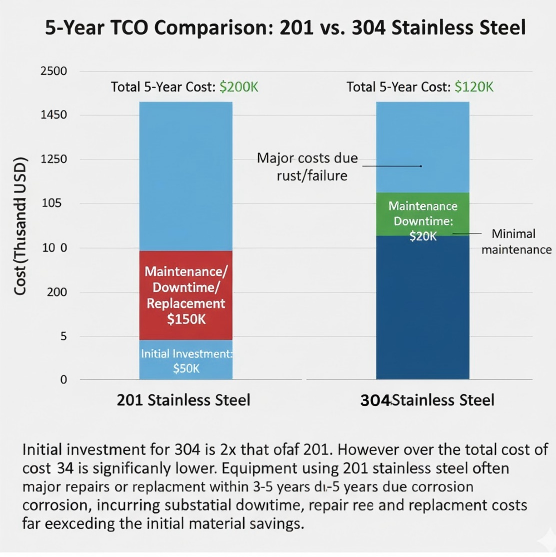

- Thép không gỉ 304: Đầu tư ban đầu cao hơn, nhưng chi phí bảo trì lâu dài thấp hơn do khả năng chống gỉ và chống mài mòn tuyệt vời.

👉 Mẹo: Khi đánh giá máy đóng gói để ăn vặt, máy đóng gói khoai tây chiên, hoặc thiết bị đóng gói thức ăn cho thú cưng, tính toán tổng chi phí sở hữu (TCO), không chỉ là giá mua.

Ứng dụng trong bao bì thực phẩm

- Máy đóng gói thức ăn cho thú cưng: Thép không gỉ 304 đảm bảo an toàn thực phẩm và ngăn ngừa ô nhiễm.

- Máy đóng gói khoai tây chiên: Vì dầu và muối làm tăng tốc độ ăn mòn nên 304 là lựa chọn ưu tiên để duy trì vệ sinh và kéo dài tuổi thọ của máy.

- Băng tải / Băng tải mô-đun: Khả năng chống mài mòn cao và dễ vệ sinh, thích hợp cho việc vận chuyển thực phẩm liên tục.

- Thang máy gầu và sàn làm việc: Độ bền vật liệu đáng tin cậy đảm bảo tính ổn định trong các dây chuyền đóng gói hạng nặng.

- Máy đóng gói Flow Wrapper & Pouch: Bề mặt nhẵn giúp giảm ma sát, đảm bảo bịt kín chính xác và giảm thiểu bảo trì.

- Máy kiểm tra cân và máy dò kim loại: Độ chính xác lâu dài và tuân thủ tiêu chuẩn an toàn thực phẩm.

- Phụ tùng & Băng tải bát: Sử dụng các thành phần thép không gỉ 304 giúp giảm thiểu thời gian chết và chi phí thay thế

Tại sao thép không gỉ 304 là lựa chọn thông minh hơn cho thiết bị đóng gói

- An toàn thực phẩm là trên hết – Thép không gỉ 304 được FDA chấp thuận và có khả năng chống ăn mòn cao, lý tưởng để tiếp xúc trực tiếp với thực phẩm.

- Tuổi thọ máy dài hơn – Tính chất cơ học mạnh hơn giúp giảm nhu cầu thay thế thường xuyên, giúp bạn tiết kiệm tiền.

- TCO (Tổng chi phí sở hữu) thấp hơn – Mặc dù thoạt nhìn có vẻ rẻ hơn, nhưng chi phí bảo trì, thay thế phụ tùng và thời gian ngừng hoạt động cao hơn thường khiến nó tốn kém hơn về lâu dài.

- Vệ sinh và làm sạch tốt hơn – Bề mặt nhẵn mịn của thép 304 giúp dễ dàng vệ sinh, ngăn ngừa sự phát triển của vi khuẩn và đảm bảo tuân thủ máy đóng gói thực phẩm tiêu chuẩn.

Lời khuyên thiết thực cho người mua

Khi đánh giá thiết bị đóng gói thực phẩm nhà cung cấp, sau đây là một số mẹo để tránh những cạm bẫy thường gặp:

- Nhìn xa hơn giá cả – Tính toán TCO (chi phí mua hàng + vận chuyển + bảo hiểm + thuế + lắp đặt + đào tạo + năng lượng + bảo trì + phụ tùng thay thế + thời gian ngừng hoạt động).

- Kiểm tra chứng nhận – Đảm bảo thép không gỉ và thiết bị tổng thể tuân thủ tiêu chuẩn an toàn thực phẩm chẳng hạn như CE, FDA hoặc 3-A.

- Yêu cầu thông số kỹ thuật vật liệu chi tiết – Kiểm tra xem nhà cung cấp có đang sử dụng thép không gỉ 304 ở tất cả các khu vực tiếp xúc với thực phẩm và khu vực quan trọng.

- Nghĩ dài hạn – Dành cho các ứng dụng có năng suất cao như máy đóng gói khoai tây chiên hoặc tốc độ cao máy đóng gói thực phẩm tự động, độ bền và vệ sinh quan trọng hơn số tiền tiết kiệm ban đầu nhỏ.

Suy nghĩ cuối cùng: Chất lượng là khoản đầu tư tốt nhất

Trong thế giới của máy đóng gói công nghiệp, các vật liệu bạn chọn ngày hôm nay sẽ định hình hiệu quả sản xuất, chi phí bảo trì và danh tiếng thương hiệu của bạn trong tương lai. Trong khi thép không gỉ 201 có thể giảm chi phí ban đầu của bạn, thép không gỉ 304 mang lại độ tin cậy, vệ sinh và tiết kiệm lâu dài—đặc biệt là trong các ngành công nghiệp như đồ ăn nhẹ, bao bì khoai tây chiênthực phẩm đông lạnh và thức ăn cho thú cưng.

Tại ĐẦY ĐỦ GÓI (www.fill-package.com), chúng tôi hiểu tầm quan trọng của việc lựa chọn vật liệu trong thiết kế thiết bị. băng tải, băng tải mô-đun, thang máy xô, nền tảng làm việc, bàn đóng gói quay, máy cân nhiều đầu, máy cân tuyến tính, máy đếm gói, máy đóng gói túi, Máy VFFS, phụ tùng thay thế, Và máy dò kim loại được chế tạo bằng thép không gỉ cấp thực phẩm để đảm bảo độ tin cậy và vệ sinh lâu dài.

💡 Thách thức lớn nhất của bạn khi lựa chọn vật liệu cho thiết bị đóng gói là gì—chi phí, độ bền hay tính tuân thủ? Hãy chia sẻ suy nghĩ của bạn trong phần bình luận bên dưới nhé!