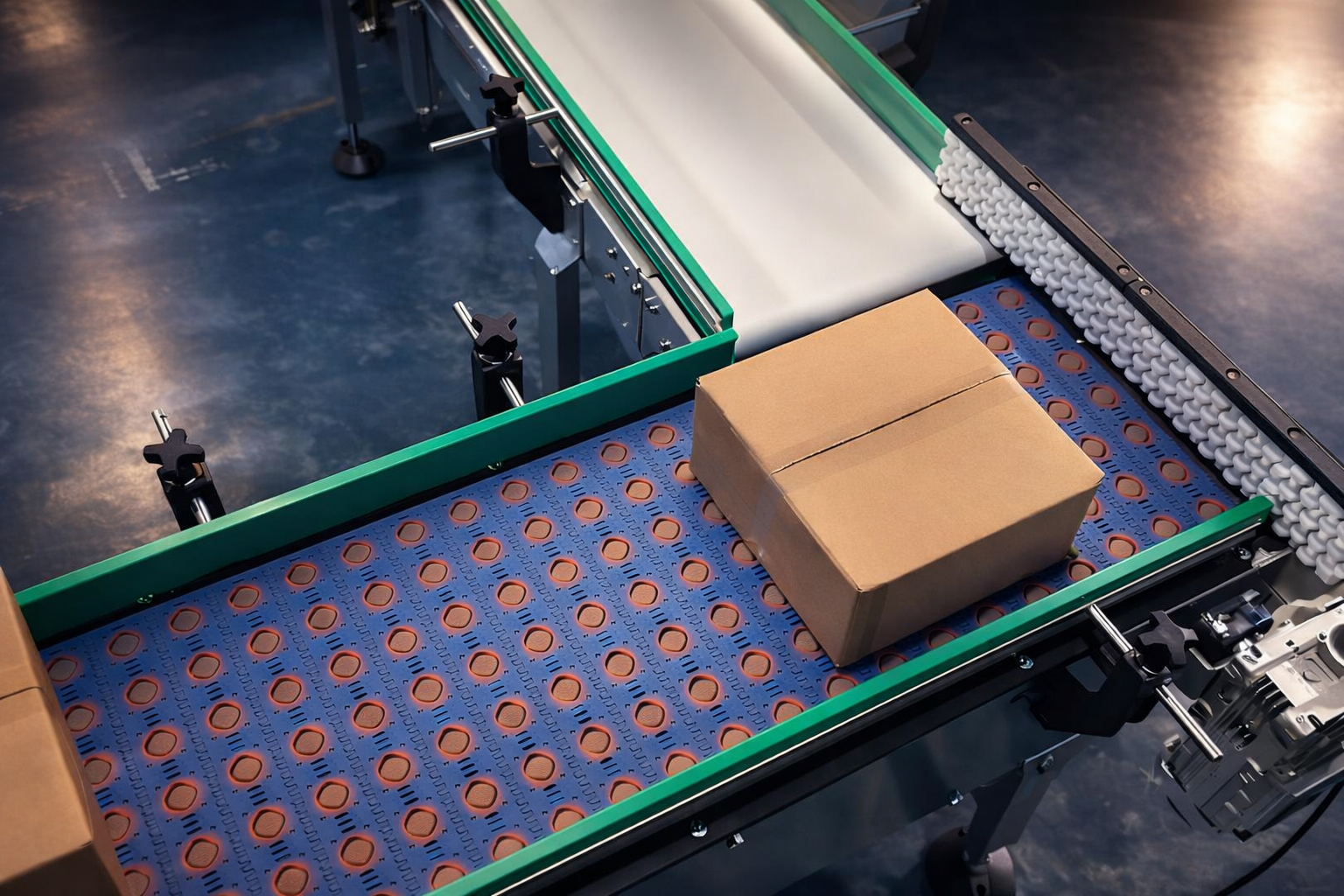

Technical Resource: Small Pitch Modular Conveyor Belts (Pitch less than 25.4mm)

Explore the complete technical guide to small pitch modular conveyor belts (≤1 inch pitch), designed for engineers, maintenance managers, and procurement specialists. This page delivers in-depth technical specifications, practical application guides, and essential maintenance advice for systems used in demanding food processing and packaging environments. Find the data you need to select, install, and maintain the right plastic modular conveyor belt for your line.

Introduction for the Technical Professional

This resource is designed for the engineers, maintenance managers, and procurement specialists who build and optimize the modern sistema de cinta transportadora modular. We understand that for you, a cinta transportadora modular de plástico is not just a component; it’s a critical factor in line efficiency, product integrity, and operational uptime. The right modular conveyor belt design ensures smooth product flow and minimizes downtime.

Small Pitch Modular Belt Series: A Detailed Breakdown

Based on the Caiyang product catalog, the following series fall into the small pitch category. Each is engineered for specific performance characteristics.

Category 1: Micro Pitch (8mm - 12.7mm)

Serie | Paso | Common Surfaces | Key Characteristics & Applications |

FP-0800 | 8mm (0.315″) | Parte superior plana | The smallest pitch available, designed for extremely tight “knife-edge” transfers, preventing small products from getting trapped. Perfect for confectionery, small electronics, or pharmaceutical vials. |

FP-12700 Series | 12.7mm (0.5″) | Flat Top, Perforated, Raised Rib | A highly versatile series. The 0.5″ pitch provides an excellent balance between a small transfer gap and robust strength. A popular choice for modular belt conveyor for food packaging applications like cookies and crackers. |

Category 2: Compact Pitch (15mm - 19.05mm)

Serie | Paso | Common Surfaces | Key Characteristics & Applications |

FP-15000 & FP-15200 | 15mm / 15.2mm | Flat Top, Perforated, Non-Slip | Excellent for applications requiring smooth, stable transport. The non-slip surface is ideal for incline/decline applications in quick-service restaurants (QSR) and food processing. |

FP-19050 & FP-19051 | 19.05mm (0.75″) | Flat Top, Perforated, with Flights/Cleats | A robust 0.75″ pitch belt that can be fitted with various flights. This makes it a top choice for elevating bulk products, a common requirement in many modular conveyor belt for packaging lines. |

Category 3: Medium-Small Pitch (25mm - 25.4mm)

| Serie | Paso | Common Surfaces | Key Characteristics & Applications |

| FP-25000 | 25mm (0.984″) | Perforated, Raised Rib | Specifically noted for its suitability in spiral conveyors (coolers, proofers, freezers). The 25mm pitch provides the strength needed for vertical conveying. |

Engineering, Materials & Maintenance

Design for Durability & Hygiene

- Modular Conveyor Belt Durability: Our belts are constructed from high-quality polymers like POM and PP, which offer excellent tensile strength and resistance to wear and fatigue. The rod-and-hinge design distributes stress evenly, leading to a longer service life compared to monolithic belts.

- Hygienic & Easy-Clean Design: For the food industry, a hygienic modular conveyor belt is non-negotiable. Our open-hinge designs and smooth surfaces prevent bacteria harborage. This makes for an easy clean modular conveyor belt, significantly reducing sanitation time. For applications requiring frequent sanitation, our modular conveyor belt washdown design features materials and construction that withstand aggressive cleaning agents and high-pressure water.

Materiales

- POM (Polyoxymethylene): The default choice. Excellent tensile strength and low friction.

- PP (Polypropylene): Superior chemical resistance. Often used for food grade modular conveyor belt aplicaciones.

- PE (Polyethylene): Ideal for low-temperature applications (e.g., freezers).

Maintenance & Troubleshooting

- Problem: Belt jumping on sprockets.

- Causa: Incorrect tensioning, worn-out sprockets, or misalignment.

- Solución: Check tension. Inspect sprocket teeth for wear. Verify alignment.

- Problem: Excessive belt wear on the edges.

- Causa: Misalignment causing the belt to rub against side rails.

- Solución: Re-align the conveyor frame and wear strips.

- Problem: Hinge points breaking.

- Causa: Overloading or using an incorrect material for the operating temperature.

- Solución: Verify the load and confirm the material’s temperature range.

Producto relacionado

How to Order & Request Technical Support

- Existing Belt Series (if known): e.g., “CY-19050”

- Paso: (e.g., 19.05mm or 0.75″)

- Belt Width & Length:

- Tipo de superficie: (e.g., Flat Top, Perforated 20% Open)

- Application Details: (Product, temperature, load)

Related Blogs:

1.Why Small-Pitch Modular Conveyor Belts Are Essential for Precision Product Handling

2.How to Choose the Right Small-Pitch Modular Conveyor Belt for Your Packaging Line

3.Small-Pitch Modular Conveyor Belt vs Standard Modular Belt: Which Fits Your Line?

Frequently Asked Questions (FAQ) for Technical Professionals

This is a critical decision. Use a cinta transportadora modular in situations requiring flexibility, durability, and ease of maintenance. They excel in applications with curves, inclines, or where drainage and airflow are needed. A flat belt is a simpler, lower-cost option suitable only for straight, simple conveying of non-critical products where belt replacement of the entire loop is acceptable.

The process of how to choose a modular conveyor belt involves three main steps. First, define your product (size, weight, stability). This determines the required pitch and surface type. Second, consider the conveyor path (straight, curved, incline). This dictates the belt series and need for accessories like flights. Finally, evaluate the environment (temperature, chemicals, sanitation requirements). This determines the optimal material (POM, PP, PE).