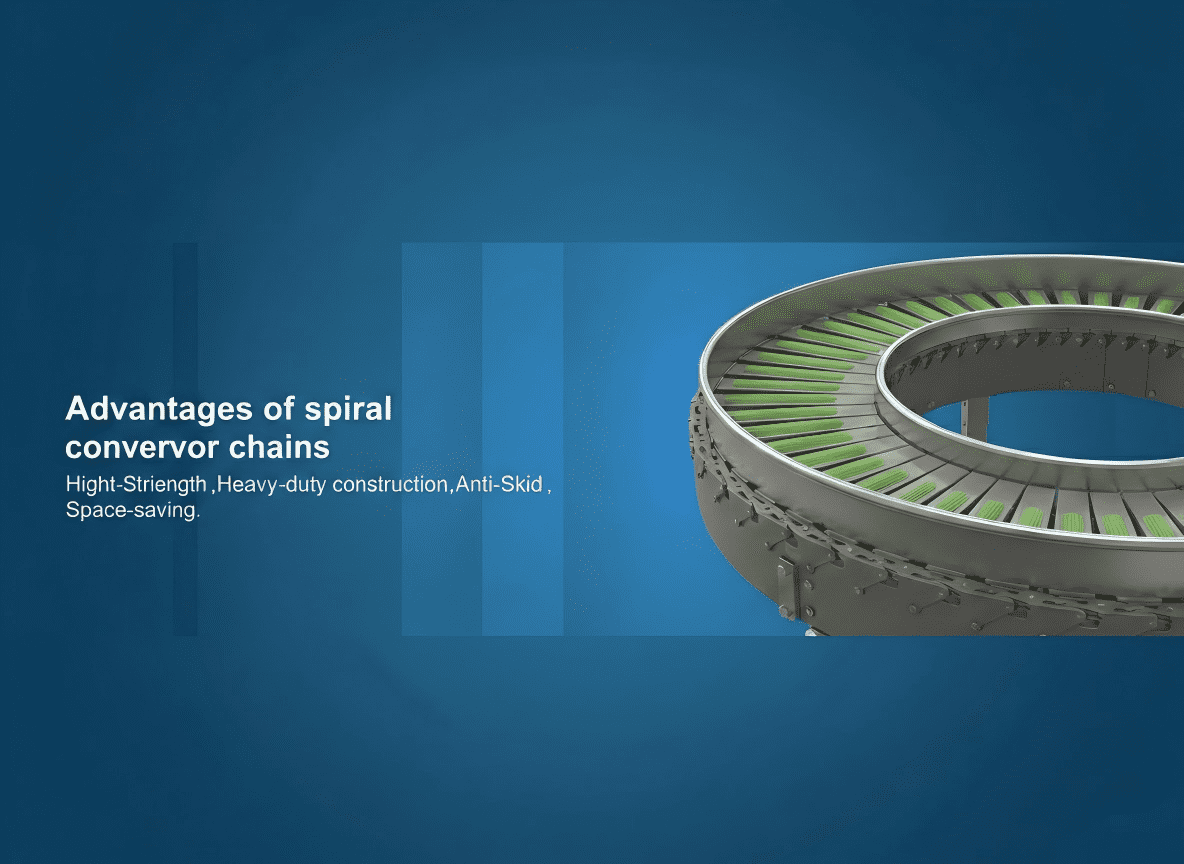

High-Performance Chains for Spiral & Vertical Conveying

Maximize your production floor space and achieve seamless elevation changes with our durable plastic flat top chains, specifically designed for the demanding requirements of spiral and vertical conveyors.

Plastic Flat Top Chains for Spiral Conveyors

Key Advantages of Spiral Conveyor Chains

High-Strength, Heavy-Duty Construction

Optimized for Vertical and Helical Movement

Anti-Skid and High-Grip Surface Options

Space-Saving Vertical Conveying

Our Spiral Conveyor Chain Series

Serie | Características principales | Aplicaciones comunes |

1873 Series | 38.1mm pitch. Available with or without bearings. Options for anti-skid rubber top surfaces. | General-purpose spiral conveying, cooling and proofing lines, accumulation towers. |

1875 Series | 38.1mm pitch. A split-chain design for ultra-wide spiral conveyors. | Handling extra-wide products, dual-lane spiral systems. |

3873 Series | 38.1mm pitch. The heavy-duty flagship for spiral systems. High tensile strength and multiple anti-skid options. | High-load spiral elevators, demanding industrial applications, long-term buffering. |

Material and Technical Specifications

Material and Technical Specifications

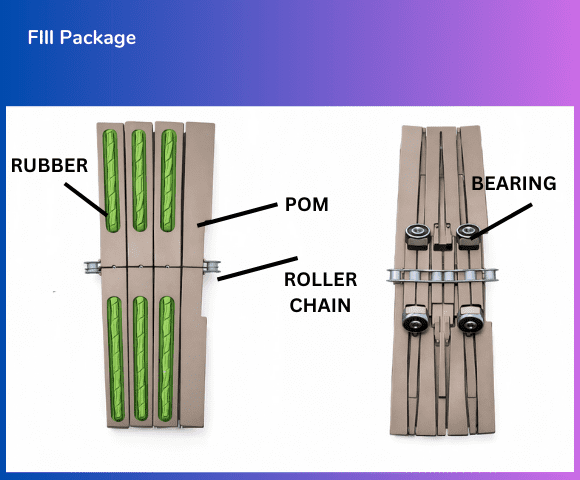

•Materiales:

- Chain Body: Acetal (POM) for excellent strength and low friction.

- Anti-Skid Surface: Co-molded Rubber or TPU for high-grip applications.

- Pins: Available in engineered plastic or Stainless Steel for maximum strength and corrosion resistance.

- Tensile Load: Up to 4,000 N, suitable for tall, heavy-laden spirals.

- Rango de temperatura: Typically -20°C to +80°C, suitable for a wide range of environments.

Applications for Spiral Conveyor Systems

- Vertical Elevation/De-elevation: Moving products between different floors or production levels.

- Accumulation and Buffering: Providing a first-in, first-out (FIFO) buffer between upstream and downstream processes to absorb micro-stops and improve line efficiency.

- Cooling and Proofing: Allowing products like baked goods to cool or dough to rise over a long period in a compact, climate-controlled space.

- Freezing: Transporting products through a spiral freezer for rapid, individual quick freezing (IQF).

Producto relacionado

A spiral conveyor chain is a specialized type of plastic flat top chain designed specifically for helical (spiral ) conveyor systems. These chains are engineered to handle the unique demands of vertical elevation, accumulation, and buffering in a compact footprint. They feature a heavy-duty construction, tight turning radius, and stable flat surface to ensure products remain upright and secure during vertical transport.

An anti-skid surface is a co-molded rubber or TPU top layer that provides exceptional grip. It is essential for applications involving elevation changes, high-speed operation, or products prone to slipping. Anti-skid chains ensure products stay in place even on inclines, preventing jams and improving overall system reliability.

Yes. Our spiral series, particularly the 3873, are designed for heavy-duty applications with tensile loads up to 4,000 N. They feature robust frames and high-strength pins (available in stainless steel) to ensure long life and reliable performance in demanding, 24/7 operations

All our spiral conveyor chains feature a standard 38.1mm (1.5-inch) pitch. This pitch is optimized for the balance between strength, flexibility, and compact design required in spiral systems.

The chain body is typically manufactured from Acetal (POM) for excellent strength and low friction. Anti-skid surfaces are co-molded from Goma o TPU for high-grip applications. Pins are available in engineered plastic or Acero inoxidable for maximum strength and corrosion resistance.

Our spiral chains typically operate in a temperature range of -20°C to +80°C, making them suitable for a wide range of environments, including cooling and ambient-temperature applications. For freezing applications, special materials may be required.

The width should be selected based on your product size and the required stability. Wider chains provide more surface area and better support for larger or unstable products. Our engineering team can help you analyze your product characteristics and recommend the optimal width for your spiral system.

Regular inspection is key. Check for signs of wear, such as cracks, elongation, or damage to the anti-skid surface. Clean the chains regularly to prevent buildup of debris. Ensure proper chain tension and alignment. Lubrication is generally not required, but in some high-load applications, a light food-grade lubricant may be beneficial.