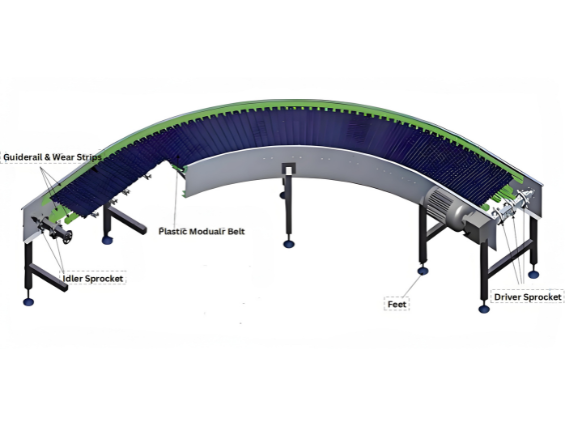

Cinta transportadora modular de plástico

Limpio. Resistente. Inteligente. Eso es modular.

La columna vertebral de su línea de producción: más que una simple correa

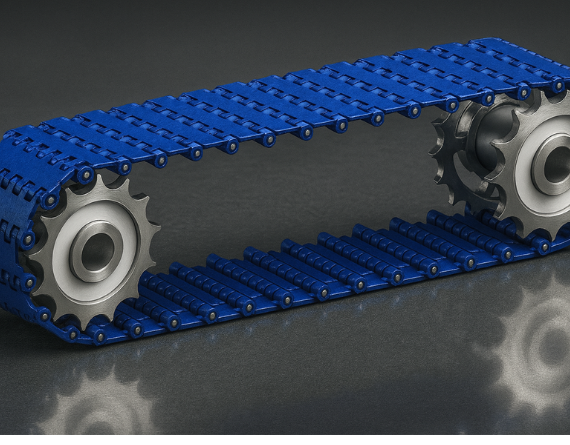

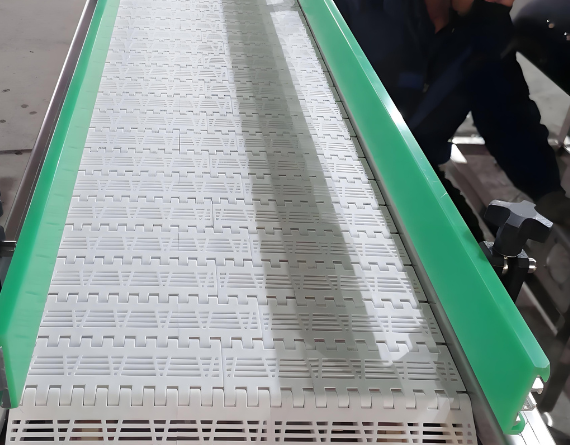

Las cintas transportadoras modulares son componentes esenciales de las líneas de envasado automatizadas modernas. Son más que simples cintas transportadoras; son fundamentales para garantizar un flujo fluido, higiénico y eficiente de productos, desde el pesaje y la organización hasta el envasado final. A diferencia de las cintas planas tradicionales, las cintas transportadoras modulares se componen de una serie de módulos de plástico entrelazados, similares a los bloques de LEGO, lo que proporciona una flexibilidad, durabilidad y facilidad de mantenimiento inigualables.

¿Su sistema transportador enfrenta estos desafíos?

Problema 1: Desalineación de la correa y movimiento serpenteante

- Utilizamos moldes de alta precisión para el moldeo por inyección de una sola pieza, lo que garantiza que las dimensiones y las posiciones de los orificios de cada módulo sean altamente consistentes.

- El control preciso del paso elimina fundamentalmente la acumulación de tolerancia que provoca el movimiento serpenteante, garantizando que la correa funcione en línea recta a lo largo de toda su longitud.

Problema 2: Difícil de limpiar, lo que promueve el crecimiento bacteriano

- Nuestras correas cuentan con un diseño de bisagra abierta que permite que los chorros de agua a alta presión pasen directamente, eliminando fácilmente los residuos.

- La superficie está especialmente tratada para ser lisa y no porosa, cumpliendo con los estándares de grado alimenticio de la FDA, inhibiendo la adhesión bacteriana y haciendo mucho más fáciles las tareas de limpieza.

Problema 3: Rotura de la correa o daño del módulo

- Insistimos en utilizar plásticos de ingeniería vírgenes 100% (como POM, PP), sin agregar nunca materiales reciclados, para garantizar una resistencia mecánica y durabilidad superiores.

- Ofrecemos una variedad de opciones de materiales para diferentes escenarios de aplicación para hacer frente a entornos hostiles como altas temperaturas, bajas temperaturas, aceite o productos químicos.

Problema 4: Reemplazo complejo, altos costos de mantenimiento

- Un exclusivo sistema de bloqueo de pasadores permite extraer e instalar fácilmente módulos individuales con solo un destornillador, sin necesidad de herramientas especiales.

- Si una parte de la correa está dañada, solo es necesario reemplazar los módulos dañados, no toda la correa, lo que reduce significativamente los costos de mantenimiento y el tiempo de reparación.

¿Qué es una cinta transportadora modular?

A cinta transportadora modular de plásticoLa banda transportadora de cadena de plástico, también conocida como banda transportadora de cadena de plástico, está construida con una serie de módulos termoplásticos unidos mediante varillas de plástico sólidas. A diferencia de las bandas tradicionales, las bandas modulares utilizan un patrón de "ladrillo", lo que permite anchos personalizados y una mayor resistencia lateral. Estas bandas son accionadas por ruedas dentadas, lo que elimina el deslizamiento y aumenta la fiabilidad, ideal para tareas de alta carga y alta precisión.

Tipos de cintas transportadoras modulares

Tipo de superficie | Descripción | Mejor caso de uso |

Parte superior plana | Superficie lisa y sólida | Uso general: transporte de productos envasados, cajas o bandejas. Fácil de limpiar. |

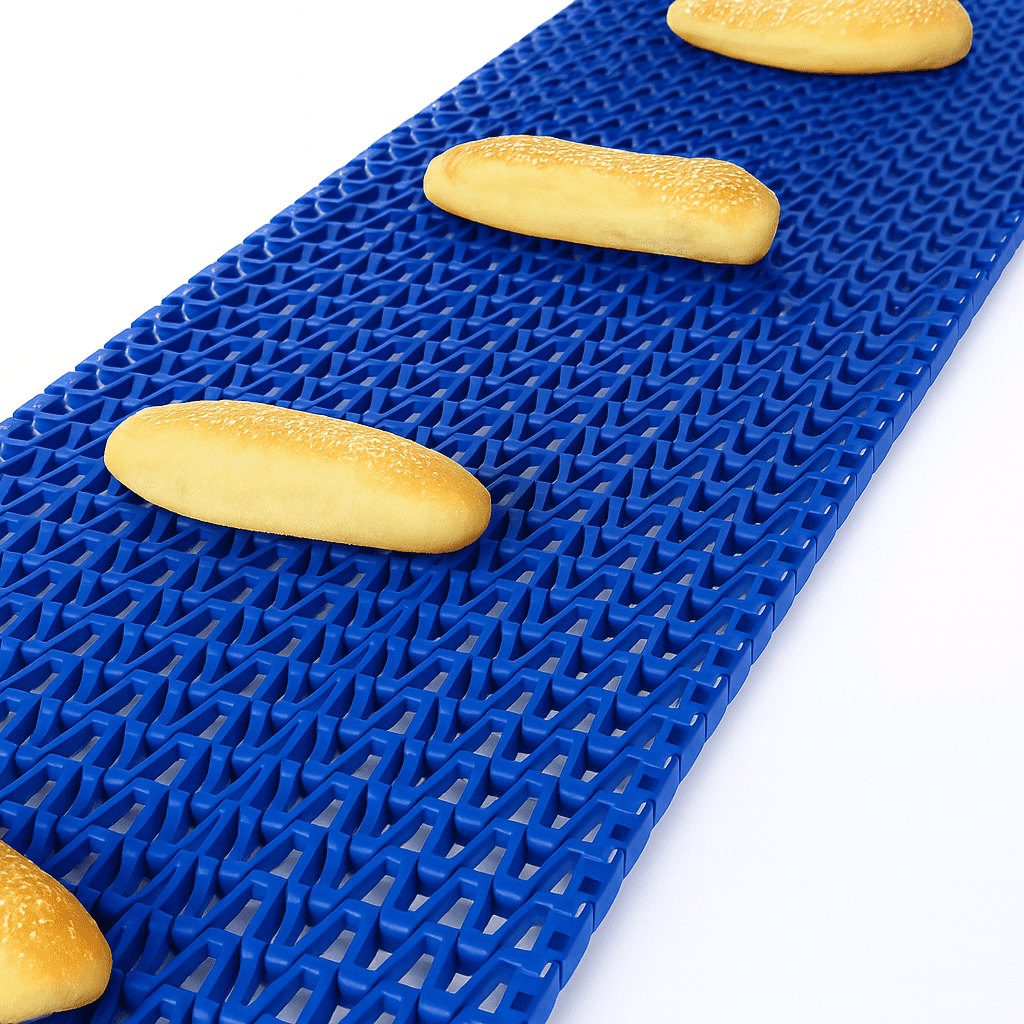

Rejilla al ras | Superficie de rejilla abierta | Aplicaciones que requieren drenaje, flujo de aire o paso de pequeños residuos (por ejemplo, lavar verduras, enfriar productos horneados). |

Costilla elevada | Costillas elevadas que recorren el cinturón | Eleva productos para permitir el procesamiento desde la parte inferior o para ejecutarlos en pistas específicas. |

Parte superior de fricción | Insertos de alta fricción en la superficie | Transportadores inclinados o declinados, evitando el deslizamiento del producto. |

Roller Top | Rodillos incrustados en la superficie | Zonas de acumulación de baja presión que permiten que los productos hagan cola sin dañar la correa ni la transmisión. |

Parte superior plana perforada | Superficie plana con pequeños agujeros. | Combina una superficie lisa con capacidades de drenaje, ideal para deshidratar productos delicados. |

La ciencia de la combinación de paso y piñón

- Paso: La distancia entre los centros de dos pines adyacentes del módulo. Los pasos comunes son 12,5 mm, 17,5 mm, 25,4 mm y 54,8 mm.

- Parcela pequeña: Ideal para transferencias estrechas y transporte de productos pequeños.

- Gran terreno de juego: Adecuado para aplicaciones de trabajo pesado y recorridos transportadores más largos.

- Coincidencia de piñones: Los dientes del piñón deben encajar perfectamente en la parte inferior de la banda. Ofrecemos piñones de plástico de ingeniería y de acero inoxidable que se adaptan a la banda y al entorno de aplicación de su elección.

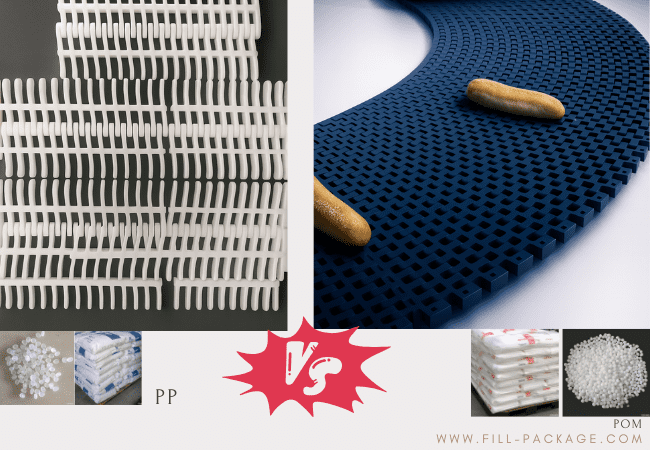

Duelo de materiales: POM vs. PP

POM (Polioximetileno): El todoterreno

- Ventajas principales: Alta resistencia mecánica, excelente resistencia al desgaste, bajo coeficiente de fricción.

- Escenarios aplicables: Transporte general de alimentos a temperatura ambiente, aplicaciones que requieren una superficie plana y resistente a los arañazos.

- Recomendación: Para la mayoría de aplicaciones de transportadores de embalaje estándar, POM es la opción más rentable y confiable.

PP (Polipropileno): La opción económica y resistente a los químicos

- Ventajas principales: Excelente resistencia química, buena resistencia a la fatiga, rentable.

- Escenarios aplicables: Procesamiento primario de productos que requieren lavado frecuente (verduras, frutas, mariscos), ambientes con sustancias ácidas o alcalinas.

- Recomendación: Cuando la resistencia química y el costo son las principales consideraciones, el PP es la opción ideal.

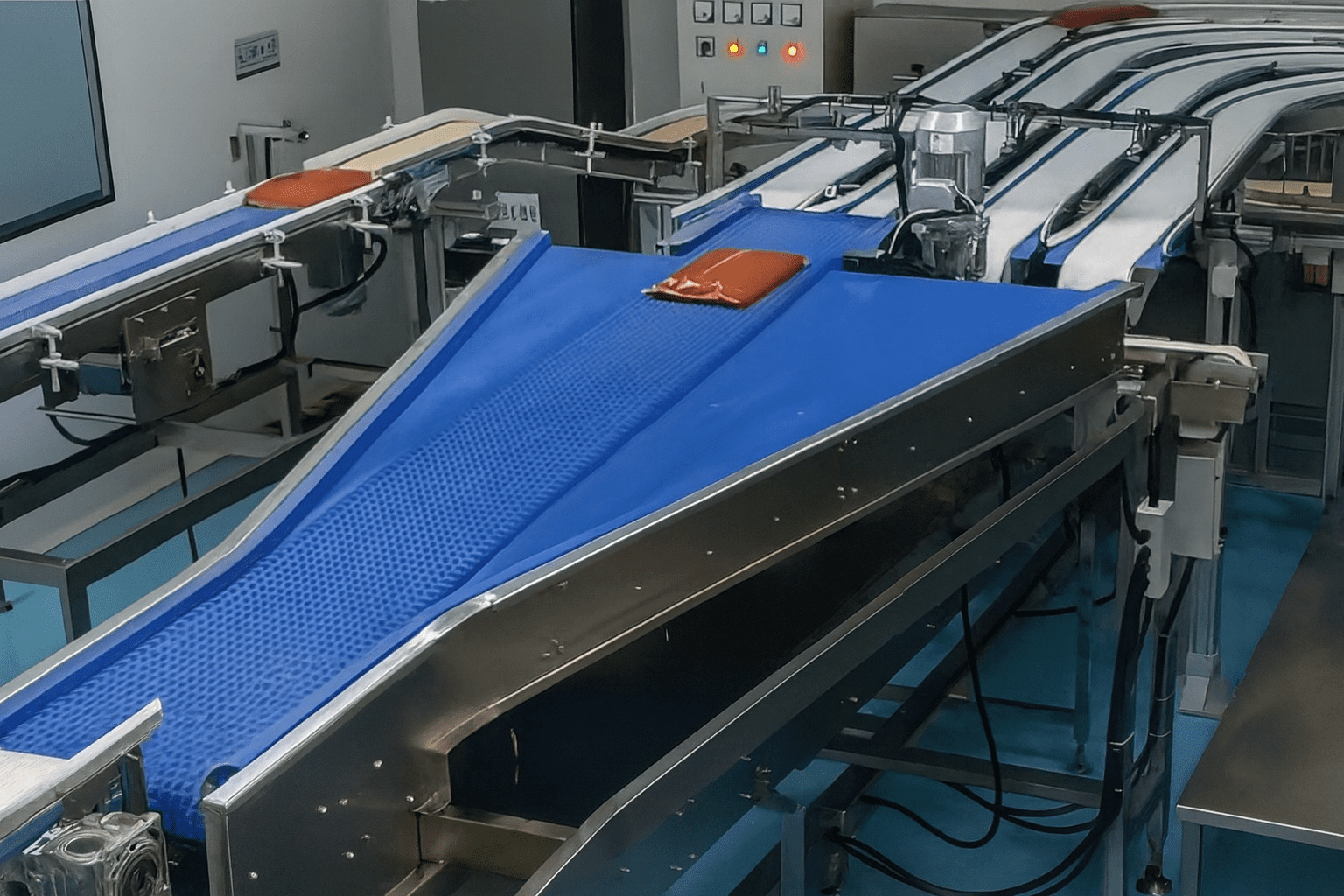

Aplicaciones industriales

Cintas transportadoras modulares Se utilizan ampliamente en muchas industrias debido a su versatilidad y facilidad de limpieza:

| Industria | Ejemplos de aplicación |

|---|---|

| Procesamiento de alimentos y bebidas | Líneas de lavado y envasado de carnes, mariscos, productos horneados, frutas y verduras. |

| productos farmacéuticos | Transporte de comprimidos, cápsulas y frascos de líquido en ambientes estériles. |

| Líneas de automoción y baterías | Transporte de componentes pesados, montaje de módulos de baterías eléctricas. |

| Embalaje y manipulación de contenedores | Botellas, latas y cajas: transporte estable y acumulación suave. |

| Comercio electrónico y almacenamiento | Clasificación y enrutamiento de paquetes de alta velocidad en centros logísticos. |

| Procesos especiales | Enfriamiento, secado, lavado: los diseños con rejilla al ras y tapa perforada son ideales. |

Consejos de mantenimiento

- Inspección de rutinaRevise periódicamente si hay grietas, desgaste o módulos rotos. Las piezas dañadas se pueden reemplazar individualmente sin herramientas.

- LimpiezaUtilice limpiadores aptos para alimentos para mantener la higiene. Los diseños de rejilla abierta son especialmente fáciles de enjuagar y desinfectar.

- Alineación de la transmisión:Asegúrese de que las ruedas dentadas y los ejes estén alineados para un seguimiento suave y para evitar saltos o desgaste.

- Marco y accesorios: Revise las guías, los rieles laterales y los motores para evitar vibraciones o atascos de material.

Cómo elegir el cinturón adecuado: guía paso a paso

- Identificar la aplicación: ¿Qué estás transmitiendo? ¿Cuáles son las condiciones ambientales?

- Elija el tipo de superficie: Parte superior plana, rejilla al ras, etc.

- Determinar el tono: Mida la distancia entre los pines del módulo.

- Seleccione el material: POM o PP.

- Especifique el ancho y el largo.

Principales beneficios de las bandas transportadoras modulares de plástico

Indicadores de reemplazo:

- Grietas visibles o daños en los módulos.

- Alargamiento de la correa, lo que provoca un acoplamiento deficiente de la rueda dentada.

- Desgaste severo en la parte inferior de la correa o de los dientes de la rueda dentada.

- Cumple con las normas de la FDA y el USDA: Todos nuestros cinturones de grado alimenticio están fabricados con materiales que cumplen con las regulaciones de la FDA y el USDA.

- Certificación ISO 9001: Nuestros procesos de fabricación cumplen estrictos estándares de gestión de calidad.

- 100% Plástico virgen: Garantizamos que todas nuestras correas están fabricadas con plásticos de ingeniería vírgenes 100%, lo que garantiza la máxima resistencia y durabilidad.

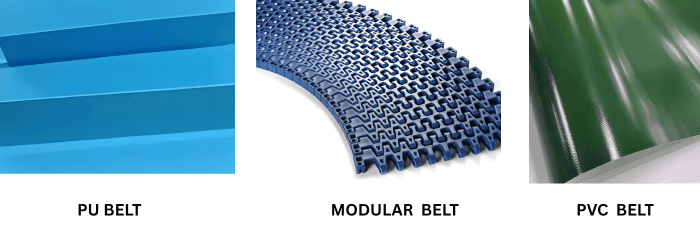

- Banda transportadora modular vs. bandas de PVC y PU

Característica | Cinturón modular | Cinturón de PVC | Cinturón de PU |

Estructura | Módulos de plástico entrelazados | Tejido de una sola pieza con revestimiento de PVC | Tejido de una sola pieza con revestimiento de PU |

Durabilidad | ⭐⭐⭐⭐⭐ (Excelente) | ⭐⭐⭐ (Bueno) | ⭐⭐⭐⭐ (Muy bueno) |

Reparabilidad | ⭐⭐⭐⭐⭐ (Reemplazar un solo módulo) | ⭐ (Reemplazar toda la correa) | ⭐ (Reemplazar toda la correa) |

Higiene | ⭐⭐⭐⭐⭐ (Fácil de limpiar) | ⭐⭐ (Dificil de limpiar) | ⭐⭐⭐ (Moderado) |

Personalización | ⭐⭐⭐⭐⭐ (Cualquier ancho/largo) | ⭐⭐⭐ (Limitado) | ⭐⭐⭐ (Limitado) |

Método de conducción | Positivo (Piñón) | Fricción (tambor) | Fricción (tambor) |

Costo | Medio | Bajo | Alto |

Valor a largo plazo | Excelente | Justo | Bien |

Producto relacionado

El cinta transportadora modular Representa un avance en la tecnología de transporte. Con una resistencia superior, fácil limpieza, mínimo mantenimiento y configuraciones flexibles, se ha convertido en la opción preferida para las operaciones modernas de fabricación y envasado.

Ya sea que manipule alimentos, productos farmacéuticos, repuestos de automóviles o paquetes de comercio electrónico, un cinta transportadora modular de plástico El sistema garantiza el rendimiento, la higiene y la escalabilidad. Invertir en sistemas transportadores de banda modulares significa preparar su producción para el futuro: eficiente, adaptable y sostenible.

La capacidad de carga depende del tipo de correa, el ancho y el tamaño de la rueda dentada, pero las correas modulares pueden manejar fácilmente aplicaciones de trabajo medio a pesado, a menudo 2 o 3 veces más resistentes que las correas tradicionales.

Sí. Ofrecemos materiales plásticos que cumplen con las normas FDA/USDA con diseños de rejilla abierta y estructuras fáciles de limpiar, ideales para el procesamiento de carnes, mariscos, productos horneados y productos agrícolas.

Por supuesto. Esa es una de las mayores ventajas: cada módulo es reemplazable, lo que minimiza el tiempo de inactividad y los costos de mantenimiento.

En absoluto. Los sistemas modulares están diseñados para ofrecer flexibilidad. Puede cambiar el ancho y la longitud de la banda, y añadir transferencias o guías fácilmente con herramientas básicas.

Con módulos con superficie de fricción o con grapas, estas correas ofrecen un agarre fuerte en pendientes de hasta 20°, lo que las hace perfectas para aplicaciones de transporte vertical.

No necesitan lubricación. Funcionan en seco y limpios, lo que ayuda a evitar la contaminación y reduce el tiempo de mantenimiento.