Introduction: The Hidden Articulation Point

In the complex choreography of a packaging line, thousands of movements happen every minute. Boxes are pushed into position, filling heads rise and fall, labels are precisely applied, and products are diverted and sorted.

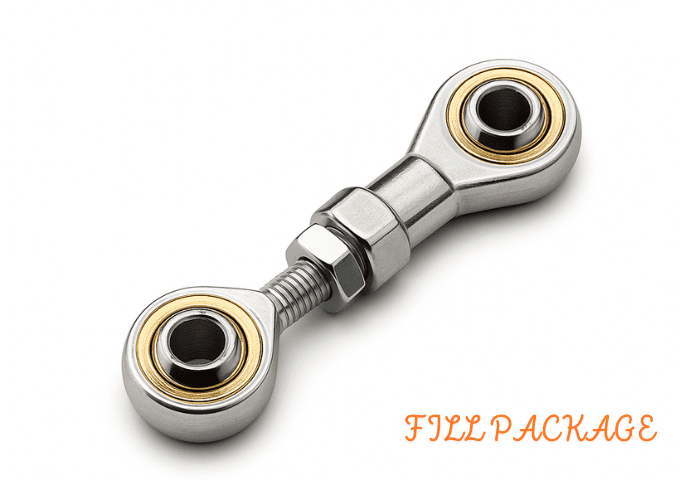

Behind each of these movements, there is often a small but critical component working silently to ensure smooth, precise motion: the cojinete del extremo de la varilla.

Also known as a Heim joint, Rose joint, o cojinete de extremo de varilla esférica, the rod end bearing is the “flexible joint” of packaging machinery. Consequently, it serves as the articulation point that allows linkages to move freely while compensating for misalignment, absorbing vibration, and handling the demanding loads of high-speed production.

A Brief History

Historical Insight: El cojinete del extremo de la varilla was originally developed during World War II for the German Air Force to enhance the flexibility and reliability of aircraft control systems.

After the war, this technology was introduced to the civilian sector and popularized by the H.G. Heim Company in North America and Rose Bearings Ltd. in the UK. As a result, “Heim joint” and “articulación de rosa“ became synonymous with the product. Today, these precision components are indispensable in industries worldwide.

Why This Guide Matters

For machine manufacturers, choosing the right rod end bearing is a decision that directly impacts machine reliability and service life. Meanwhile, for parts wholesalers, it is a fundamental component with steady demand across the packaging industry.

This guide will explore the critical role of rod end bearings in packaging machinery, the advantages of our products, and how to select the right bearing for your application.

Part 1: Rod End Bearings — The “Flexible Joints” of Packaging Machinery

What Is a Rod End Bearing?

A rod end bearing consists of a rod end body (with internal or external threads) and a spherical plain bearing. Essentially, it is a spherical sliding pair that allows angular oscillation in two planes while bearing radial loads.

In packaging machinery, this characteristic is critical because it compensates for three key challenges:

1. Installation Misalignment

In complex linkage mechanisms, perfect alignment is difficult to achieve. Fortunately, our bearings automatically adjust to accommodate slight misalignments, eliminating binding and premature wear.

2. Deflection and Vibration During Operation

At high speeds, the machine frame and linkages experience micro-deformations. Therefore, rod end bearings absorb these deflections, preventing stress concentration and ensuring smooth motion.

3. Dimensional Changes from Thermal Expansion

During prolonged operation, machines heat up and components expand. Consequently, rod end bearings ensure that motion mechanisms do not seize or bind due to thermal expansion and contraction.

Primary Application Points in Packaging Machinery

1. Cartoning and Wrapping Machines

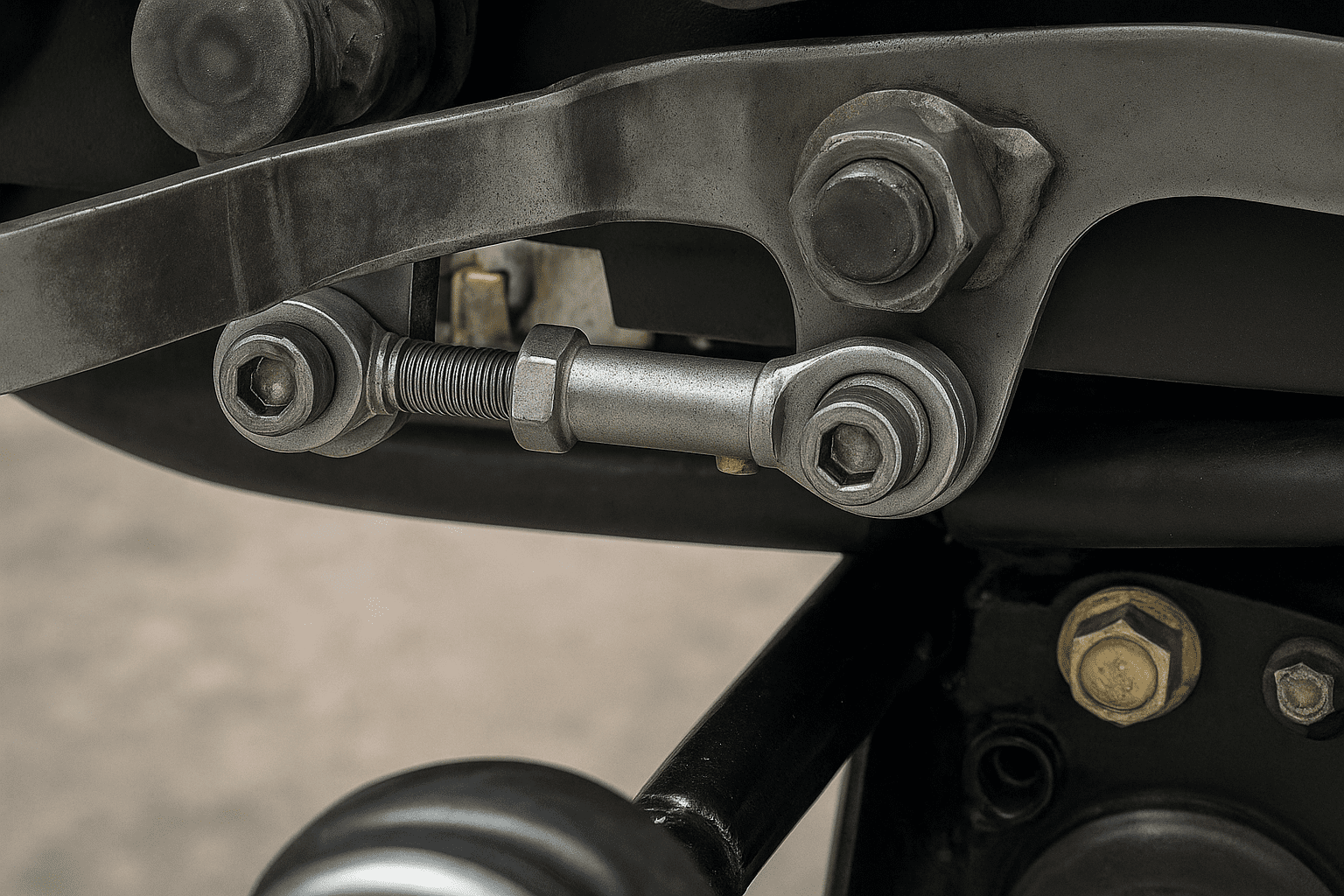

Pushers, Folding Arms, and Grippers: Rod end bearings are used in the linkages that push products into cartons or complete film wrapping. These applications demand responsive, jam-free motion with minimal backlash.

2. Filling and Capping Machines

Bottle/Can Height Adjustment: Used in linkages that control the rise and fall of filling heads, rod ends must handle cyclic impact loads.

Capping Head Drive Linkages: Additionally, they connect the drive system to the capping head (e.g., screw capping), requiring smooth rotation and angular compensation.

3. Labeling Machines

Label Gripping, Transfer, and Application Arms: In the swing arm mechanisms that grab, move, and apply labels, rod end bearings ensure absolute precision in label positioning. This is critical for brand presentation.

4. Transportador and Sorting Systems

Diverters and Guide Rod Adjustment Linkages: These ensure smooth and reliable switching actions in product routing and sorting.

Conveyor Belt Tensioning Devices: Furthermore, they maintain proper belt tension through adjustable linkages.

Part 2: Our Product’s Core Advantages

Packaging machinery operates in challenging conditions: high-speed, continuous operation, and sometimes in wet or washdown environments. Generic rod end bearings often fall short. Our products are specifically designed to meet these challenges:

Advantage 1: Exceptional Wear Resistance and Extended Service Life

(For Machine Manufacturers)

Core Materials

We use high-wear polymer composite materials for the ball socket liner (such as POM, high-performance nylon, or optional PTFE). These are paired with hardened, high-gloss steel balls (typically GCr15 bearing steel, heat-treated and precision-ground).

This combination delivers an extremely low coefficient of friction and superior wear resistance, far exceeding traditional metal-on-metal or standard engineering plastic designs.

The Result

Your machines maintain minimal play and consistent positioning accuracy even after prolonged high-speed operation. This effectively extends the overhaul cycle of your equipment and reduces the total cost of ownership for your end customers.

Ultimately, it is a powerful testament to the reliability of your equipment.

Advantage 2: Maintenance-Free and Excellent Environmental Resistance

(For All Customers)

Pre-Lubrication and Sealing

Our flagship self-lubricating (PTFE-lined) series is pre-filled with long-life lithium-based grease at the factory. Moreover, it features high-efficiency double-lip seals or O-rings.

This not only prevents internal grease leakage but also blocks the ingress of dust, fiber debris, light water splashes, and corrosive cleaning agents commonly found in packaging environments.

The Result

True “lifetime maintenance-free” operation. Machine manufacturers can simplify their after-sales service lists, while end users do not need to schedule regular downtime for lubrication. This improves equipment utilization.

This is especially suitable for food and pharmaceutical packaging industries where cleanliness and maintenance-free operation are paramount.

Advantage 3: Precise Thread Fit and High-Strength Construction

(For Machine Manufacturers)

Precision Machining

Our internal and external threads are produced using precision rolling processes with strict tolerance control. This ensures a gap-free, smooth fit with adjustment rods, cylinder connectors, and other components.

As a result, it eliminates “binding” or loosening issues during installation and simplifies your assembly process.

Robust Design

The rod end body is made from high-strength alloy steel (or stainless steel for corrosive environments) and heat-treated. Critical areas (such as the thread root and ball neck) feature reinforced designs.

Therefore, they can withstand the high-frequency alternating loads and instantaneous impacts common in packaging machinery, preventing unexpected fractures.

Advantage 4: Wide Range of Specifications

We stock a comprehensive range of sizes, from small M5/M6 rod ends used in sensor linkages to large M20/M24 rod ends for heavy-duty sealing jaw mechanisms.

We cover the most common specifications used in the packaging industry, offering:

- Male (SA Series) / Female (SI Series) Threads: To match your design requirements.

- Left-Hand / Right-Hand Threads: For turnbuckle-style tensioning linkages where rotating the rod adjusts the distance between two ends.

- Metric Sizes: M5, M6, M8, M10, M12, M14, M16, M18, M20, M22, M24, and larger.

Advantage 5: High Load Capacity

Through optimized internal structures and high-strength materials, our rod ends can withstand significant radial and axial loads. This ensures connection stability under severe working conditions.

Furthermore, our spherical inner ring design allows for a swing angle of up to 20 grados (depending on the model), effectively absorbing installation errors and mechanical deformations during operation.

Advantage 6: Fast Delivery and Expert Technical Support

We maintain a large inventory of common rod end sizes to ensure fast shipment and delivery. Additionally, our technical team can help you select the optimal component for your application, ensuring you get the performance you need without over-engineering.

Part 3: SA Series vs. SI Series — Choosing the Right Thread Type

SA Series (Male Thread / External Thread)

Diseño: The threaded shank extends from the bearing housing.

Ideal para: Screwing onto a threaded rod or into a threaded hole in a linkage arm.

Advantage: Easier to install and adjust in many applications.

SI Series (Female Thread / Internal Thread)

Diseño: The threaded hole is inside the bearing housing.

Ideal para: Screwing onto a threaded stud or bolt.

Advantage: More compact design, useful in space-constrained applications.

Selection Tip

The choice between SA and SI depends on your mechanical design and the type of connection you need to make. Both series offer the same performance characteristics; the difference is purely in the mounting method.

Part 4: Heim Joint vs. Ball Joint — Understanding the Difference

Al elegir una junta articulada, los ingenieros suelen sopesar las opciones entre una Articulación de Heim (rod end bearing) and a rótula. While both facilitate multi-angle motion transfer, their design, performance, and suitable applications differ significantly.

Característica | Rótula Heim (Cojinete de extremo de varilla) | Rótula |

Estructura | Exposed spherical bearing in “eye” casing, easy to inspect | Sealed ball stud with dust boot protection |

Tipo de carga | Optimized for high axial loads (tension/compression) | Optimized for radial loads (wheel support) |

Precisión | High rigidity, minimal play, direct force transmission | Polymer bushing absorbs vibration, less precise |

Mantenimiento | Open design; metal types need regular lubrication | Sealed design; often maintenance-free for life |

Mejor para | Packaging machinery, robotics, high-precision control systems | Passenger cars, comfort-focused applications |

Consejos de selección

When your application requires handling high tensile or compressive forces and demands maximum precision and rigidity, the Heim joint is the superior choice.

Alternatively, when your application primarily involves radial support loads and prioritizes long life, low maintenance, and vibration damping, the ball joint is more suitable.

Part 5: Selection Guide — Choosing the Right Rod End Bearing

Choosing the correct rod end bearing involves several key parameters:

Step 1: Choose the Lubrication Type

Self-Lubricating (PTFE-Lined): Suitable for low-to-medium speed, high-load applications that require maintenance-free operation or have cleanliness requirements. This is the mainstream choice in packaging machinery.

Metal-to-Metal: Ideal for extremely high-load, low-speed oscillating, or static connection applications. Requires regular grease replenishment to prevent wear and seizure.

Step 2: Calculate Load Requirements

Static Load (C₀): La carga máxima que un rodamiento puede soportar en reposo o con oscilación muy lenta. Al seleccionarlo, la carga estática máxima del equipo debe ser inferior a la carga estática nominal del rodamiento.

Dynamic Load (C): The constant load a bearing can endure for a specific life (typically one million oscillations). For dynamic applications, ensure the working load is well below the rated dynamic load.

Step 3: Determine Thread Type

Male (SA Series) vs. Female (SI Series): Does the rod end screw onto a rod or does a rod screw into it?

Left-Hand vs. Right-Hand Thread: Most are right-hand (tighten clockwise). Left-hand threads are used in turnbuckle-style linkages for tensioning, where one end has right-hand thread and the other has left-hand thread (indicated by an “L” suffix).

Step 4: Select Size and Thread Specification

Thread Size (e.g., M8, M10, M12): This is the primary size indicator. It must match the connecting rod.

Bearing Bore (d): The diameter of the spherical bearing, which determines load capacity.

Step 5: Choose Material and Surface Treatment

Rod Body Material: Los productos estándar utilizan acero al carbono de alta calidad. Para aplicaciones que requieren protección contra la corrosión, se ofrece acero inoxidable o acero al carbono con tratamiento galvanizado, niquelado o cromado.

Ball Material: Acero para rodamientos de cromo con alto contenido de carbono (GCr15), tratado térmicamente y rectificado con precisión para garantizar una alta dureza y resistencia al desgaste.

Part 6: Installation and Maintenance Guide

Installation Precautions

1. Ensure Coaxiality

Ensure the connected ends are as coaxial as possible during installation to minimize the initial deflection angle. This leaves room for deformation during operation.

2. Use Proper Press-Fitting

Use specialized tools to apply force evenly on the end face of the bearing housing. Never strike the ball or rod body to install, as this will severely damage the bearing.

3. Tighten Threads Correctly

Use a torque wrench to lock the nut to the recommended torque. This ensures a secure connection and prevents loosening under vibration.

4. Maintain Cleanliness

El área de instalación debe mantenerse limpia para evitar que el polvo, las virutas y otras materias extrañas entren en el rodamiento.

Maintenance and Inspection

Self-Lubricating Type (PTFE-Lined)

Essentially maintenance-free. However, visually inspect the PTFE liner for wear and excessive clearance periodically. Replace when the clearance exceeds the design limit.

Tipo metal-metal

Requires regular lubrication with grease (e.g., every 100 hours or monthly) via the grease fitting until fresh grease purges from the seals.

Regular Inspection (All Types)

Regularly check if the fastening nuts are loose and if the rod body is deformed or cracked.

Conclusion: An Investment in Precision and Reliability

The rod end bearing may be a small component, but its impact on a packaging machine’s performance is enormous. A low-quality rod end can lead to imprecise movements, increased maintenance, and costly downtime.

On the other hand, a high-quality rod end is a fit-and-forget component that silently ensures your machine runs smoothly and accurately for years.

By choosing to source high-precision, durable, and maintenance-free rod end bearings, you are not just buying a part. Instead, you are investing in the reliability and reputation of your machinery.

Ready to upgrade the performance and reliability of your packaging equipment? Contact us today to discuss your rod end bearing requirements and discover the advantages of partnering with a quality-focused supplier.