Stop Bottlenecks, Start Flowing: The Power of a Rotary Packing Table

How Does the Rotary Table Work? A Detailed Look

- Product Infeed: Finished products (bags, bottles, or boxes) are discharged from the upstream machine (e.g., a Máquina VFFS or a checkweigher) directly onto the rotating stainless steel tabletop.

- Accumulation & Buffering: As the table rotates at a controlled speed, it collects a large number of products, creating a buffer. If a downstream process (like manual case packing) experiences a brief delay, the table continues to collect products, preventing a line-wide shutdown.

- Guided Sorting (Optional): A fixed “spoiler” or guide arm is positioned over the table. As products rotate, this arm gently directs them towards the outer edge of the turntable, presenting them in an organized manner for the operator.

- Manual or Automated Off-take: Operators can then easily pick the organized products from the edge of the table for secondary packaging. In more advanced applications, the table can be used to feed products into another automated process, such as a case packer or labeling machine.

Key Features & Technical Specifications

Core Product Features

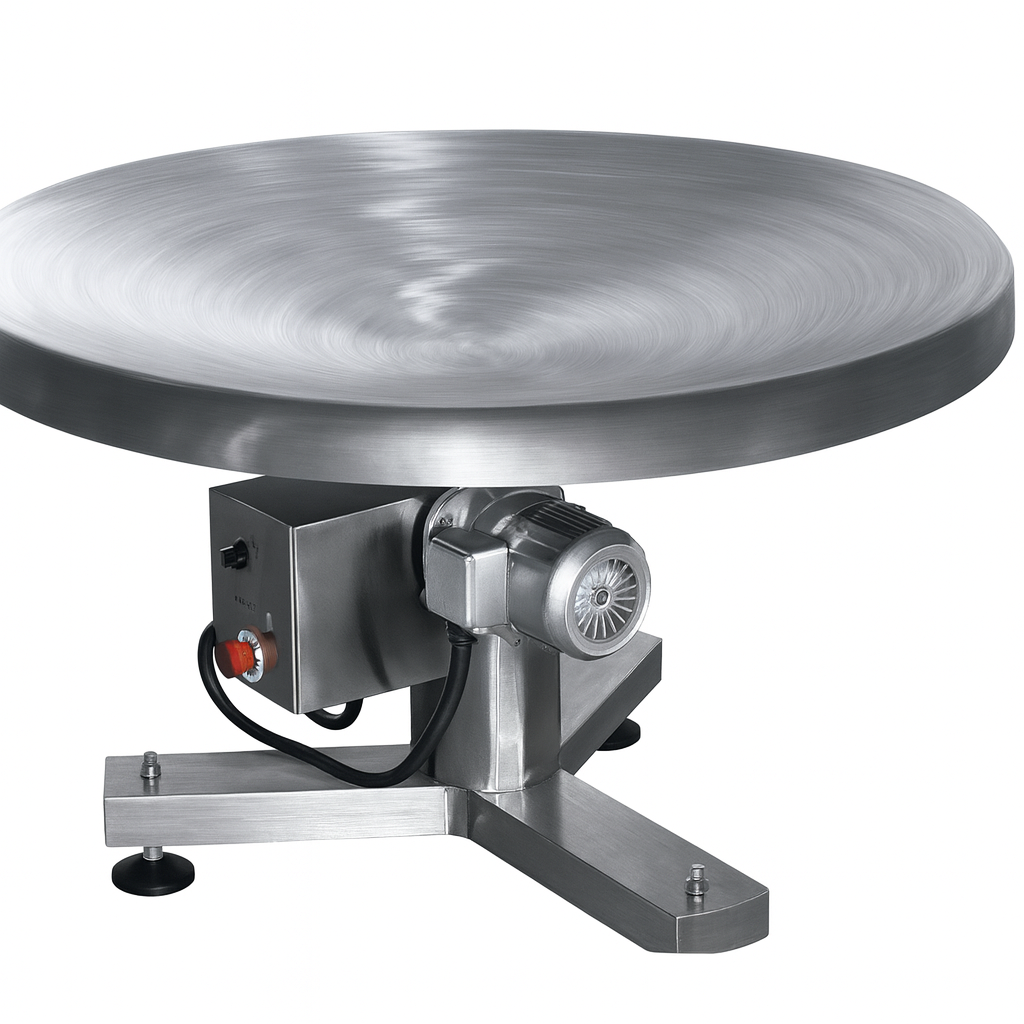

- High-Quality SUS304 Stainless Steel: The entire frame and tabletop are constructed from food-grade stainless steel, making it corrosion-resistant, durable, and ideal for hygienic environments.

- Control de velocidad variable: An intuitive frequency inverter allows for precise speed adjustments, enabling you to perfectly match the speed of your production line and product type.

- Operator Safety Design: The concave, “no-pinch” tabletop design ensures there are no trap points between the rotating surface and the stationary frame, protecting operators during use.

- Compact, Space-Saving Footprint: The circular design provides a large accumulation area within a minimal footprint, making it ideal for optimizing floor space in crowded production facilities.

- Low Maintenance Operation: With only one primary moving part and high-quality components, our turntables are exceptionally reliable and require minimal routine maintenance, reducing your total cost of ownership.

Especificaciones técnicas

Parámetro | Especificación |

Frame & Top Material | SUS304 Food-grade Stainless Steel (SUS316 optional) |

Standard Diameters | Ø1000mm, Ø1200mm, Ø1500mm (Customizable from 600mm to 2000mm) |

Standard Height | 835mm (Customizable to match your line height) |

Diseño de superficies | Cóncava, lisa, sin pellizcos |

Control de velocidad | Variable speed via frequency inverter (0-10 RPM typical) |

Motor Power | 0.25kW – 0.75kW (depending on size and load) |

Fuente de alimentación | Single-phase 220V or Three-phase 380V, 50/60Hz |

Capacidad de carga | Standard: 50kg (Customizable for heavier loads) |

Customer Case Study: Snack Food Manufacturer Boosts Efficiency

- The Challenge: After installing a new, high-speed VFFS bagger, the client found that their manual packing station couldn’t keep up. Bags would pile up and fall on the floor, causing product damage and forcing them to run the new bagger at only 60% of its capacity. The bottleneck was erasing their investment.

- The Solution: Fill-Package installed a Ø1500mm Mesa de embalaje giratoria at the exit of the VFFS machine. The table was synchronized with the bagger’s speed and included a guide arm to direct bags to the outer edge.

- The Result: The turntable provided a sufficient buffer, allowing two packers to comfortably manage the bagger’s full output. This simple addition led to a 40% increase in overall line throughput, a 90% reduction in product damage from falling, and a more organized, less stressful work environment for the staff. The investment paid for itself in under six months.

¿Por qué elegir nuestro plato giratorio industrial Lazy Susan?

Mayor eficiencia de producción:

Reduce los cuellos de botella, lo que permite un flujo continuo de producto y un mayor rendimiento.Optimización del espacio:

El diseño circular garantiza un espacio mínimo, optimizando la distribución del espacio de producción.Seguridad superior del producto:

Un manejo cuidadoso protege los productos frágiles o sensibles, minimizando los riesgos de daños.Opciones de personalización:

Diámetro, altura, configuraciones de velocidad y más, personalizados, que se adaptan a sus necesidades industriales específicas.

Absolutely. Customization is one of our core strengths. We can manufacture the table to any diameter between 600mm and 2000mm and adjust the height to perfectly match the discharge height of your existing equipment, ensuring a smooth, level transfer.

Yes. Our standard model uses SUS304 stainless steel and is designed for easy cleaning. For environments requiring high-pressure washdowns, we offer a fully sealed, IP65-rated motor and control box, along with an SUS316 stainless steel frame for maximum corrosion resistance.

Maintenance is minimal. We recommend a monthly check of the gearbox oil level and a periodic inspection of the motor and electrical connections. The robust design and high-quality components ensure years of reliable service with very little upkeep.

Yes. Every table comes equipped with a variable frequency drive (VFD). This allows operators to easily adjust the rotation speed with a simple dial, enabling them to find the perfect speed to match product flow and operator pace.

It creates a more organized and predictable workspace. Instead of reaching and bending to collect products from a pile, operators can stand in one place as the products are delivered to them at a comfortable height. The no-pinch design also eliminates a common industrial hazard, ensuring a safer environment.

Lead times can vary based on the level of customization. For standard sizes (1000mm, 1200mm), the lead time is typically 2-3 weeks. For highly customized dimensions or features, it may be 4-5 weeks. Contact us with your requirements for a precise quote and delivery schedule.

Yes, the direction of rotation (clockwise or counter-clockwise) can be easily configured based on your production line layout and workflow requirements.

We offer several options, including custom guide arms (spoilers), adjustable side rails for taller products, casters for mobility, and integration with upstream and downstream machine controls for automatic start/stop functionality.

Ready to Eliminate Your End-of-Line Bottleneck?

A Rotary Packing Table is a simple, effective, and high-ROI investment that can unlock the true potential of your packaging line. Stop letting manual packing limit your growth.

[Contact Our Engineers Today] to discuss your application and get a free, no-obligation quote for a customized solution. Let us help you design a more efficient and profitable workflow.