Introduction: Matching the Conveyor to the Task

In an automated packaging system, efficiency relies on how effectively you move product between processes. While the Vertical Form Fill Seal (VFFS) machine is the star of the show, the supporting actors—the conveyors—determine the flow.

Understanding the specific applications of belt conveyors is the first step in designing a reliable line. You cannot use a flat transport belt to elevate slippery bags, just as you shouldn’t use a standard belt for high-hygiene meat handling.

In this guide, we break down the three most critical roles conveyors play in a packaging line to help you select the right configuration.

1. The Exit Strategy: Discharge and Take-Away

Once your VFFS machine seals a bag, gravity drops it. Where does it go? This is where discharge conveyor applications entran en juego.

The primary goal here is to clear the machine outlet immediately to prevent the next falling bag from colliding with the previous one (a common cause of machine jams).

The Challenge: The product is often a finished, slippery bag that needs to be elevated from a low machine outlet to a table or check weigher.

The Solution: Nosotros usamos take away conveyor applications (Incline Conveyors).

Key Feature: These conveyors typically feature Cleated Belts (baffles) or High-Friction Rough Top surfaces. This ensures the bag is gripped securely and transported upwards without sliding back, maintaining the speed of the packaging cycle.

2. The Bridge: Transfer Between Machines

A packaging line is a chain of islands: Multihead Weigher -> Platform -> VFFS -> Metal Detector -> Rotary Table. A specific belt conveyor for packaging machines acts as the bridge between these islands.

The Challenge: Speed Synchronization. The conveyor must match the output speed of the upstream machine and the input speed of the downstream machine.

The Solution: Variable Speed Flat Belt Conveyors.

Key Feature: We integrate these with Variable Frequency Drives (VFDs). For example, when transferring packs from the discharge conveyor to a metal detector, the belt must ensure smooth, spaced-out delivery so the detector doesn’t trigger false rejects due to product clumping.

3. The Feeding: Incline Loading

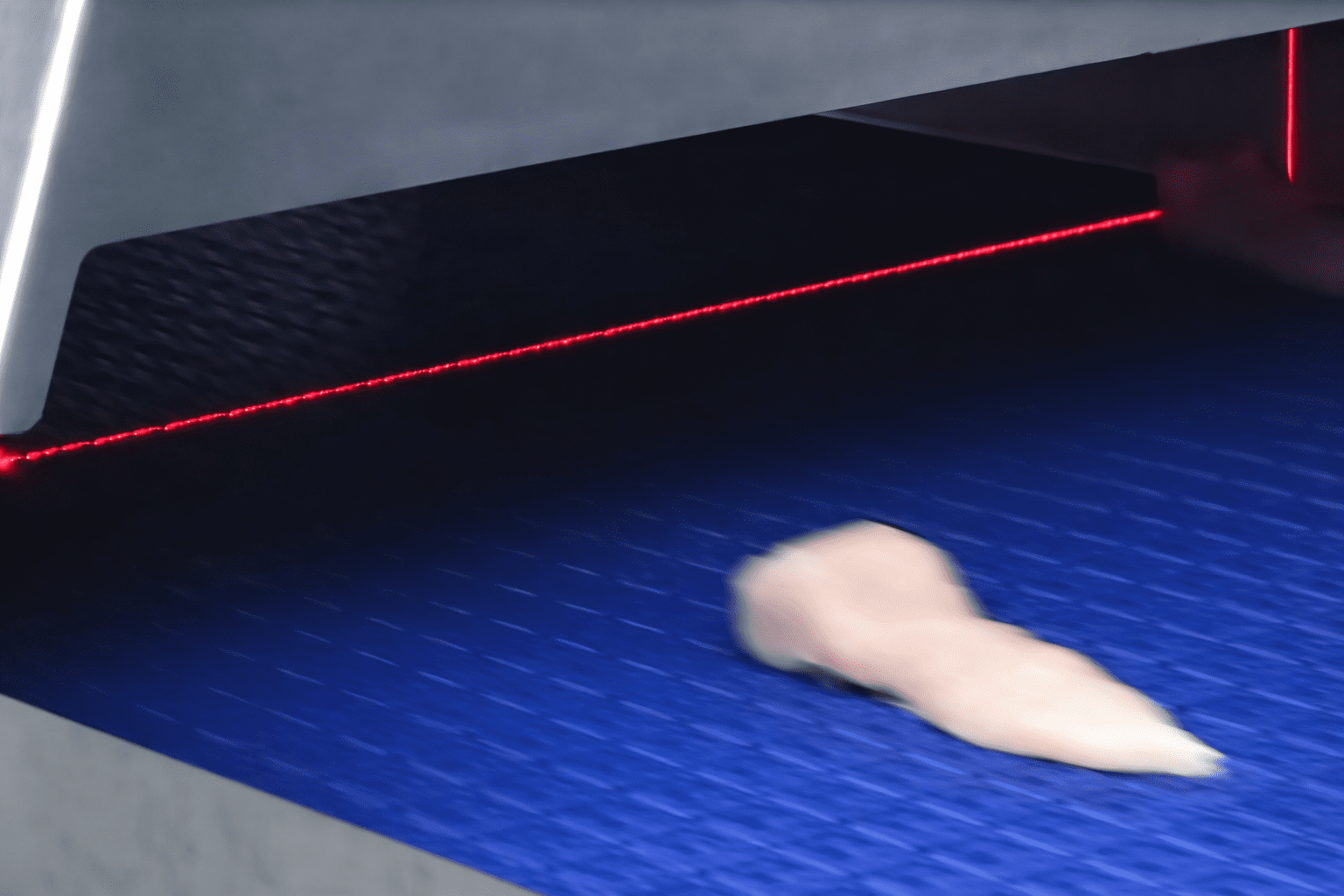

Before packaging begins, bulk product must get to the top of the weigher. While bucket elevators are common, applications of belt conveyors are also popular here, especially for sticky or fragile products.

The Challenge: Moving bulk product vertically without spillage.

The Solution: Z-Type Modular Belt Conveyors.

Key Feature: Unlike a standard bucket elevator, a Z-Conveyor uses a continuous belt with sidewalls. This prevents product from falling into chains or gears, making it a preferred choice for food hygiene applications where “easy clean” capability is required.

Conclusion: One System, Multiple Roles

Ya sea que necesites un take away conveyor to elevate finished bags or a transfer belt to feed a metal detector, the success of your line depends on choosing the right geometry and belt material.

Don’t treat conveyors as generic hardware. Define the application first, and the right conveyor solution will follow.

Need a discharge or transfer conveyor? We engineer specific belt solutions for every stage of your packaging line.