Belt Conveyor Applications in Packaging Lines

The Critical Role of Conveyors in Packaging Systems

In modern production, a transportador de banda is more than just a moving strip; it is the lifeline of your factory. Understanding the diverse applications of belt conveyors is key to designing an efficient line. From transporting raw meat to discharging finished bags from a VFFS machine, belt conveyor applications in packaging lines determine the speed, hygiene, and stability of your entire operation.

At Fill Package, we engineer application-specific conveying solutions that integrate seamlessly with your weighing and packaging machinery.

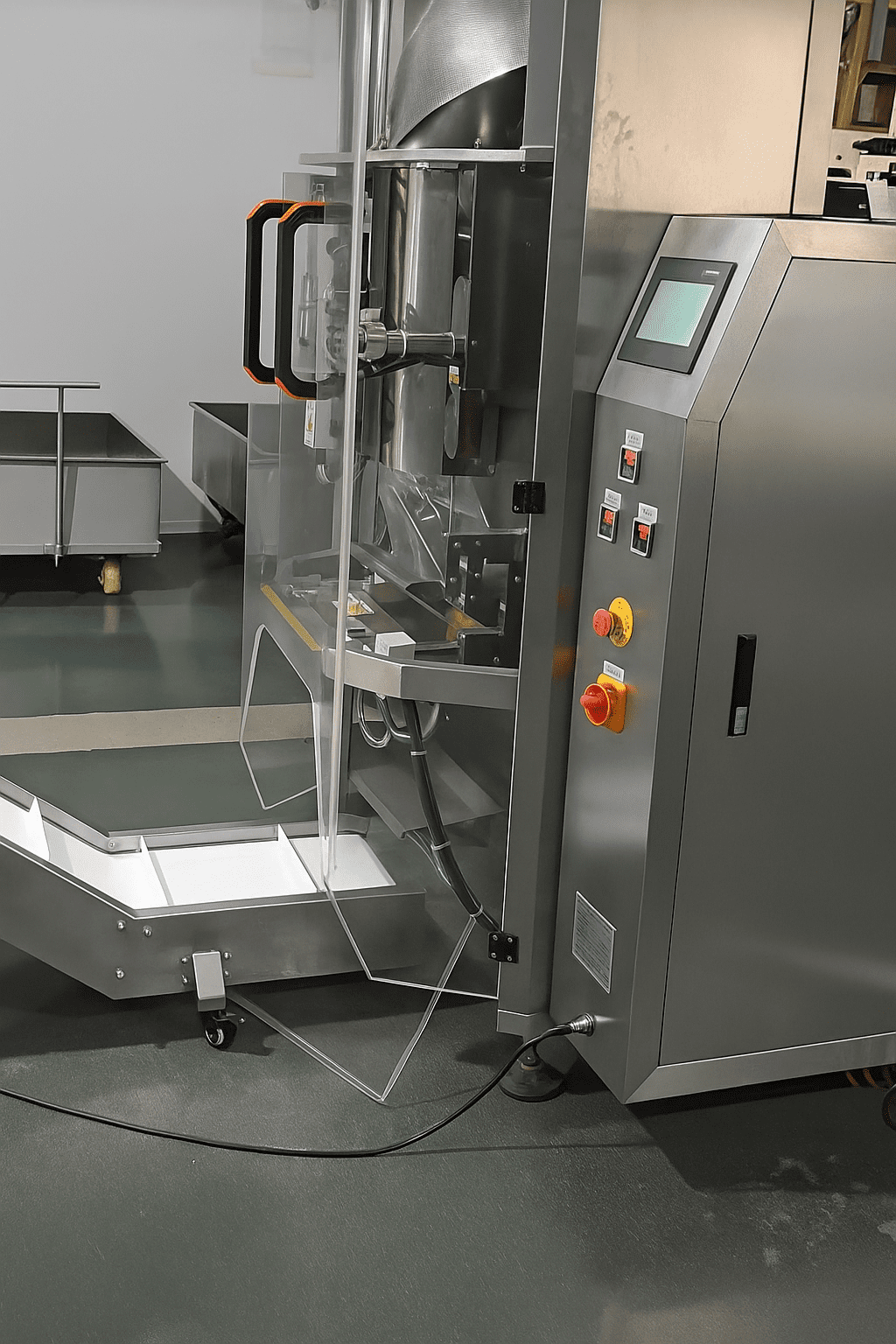

Discharge & Take-Away

Belt Conveyor for Take-Away Applications The most common application in a vertical packaging system is the discharge conveyor. After the VFFS machine seals the bag, it drops onto a belt conveyor for take-away applications. This incline conveyor elevates the finished packs to a rotary table or a check weigher.

Key Feature: High-friction or cleated belts are used to prevent bags from sliding back.

Nuestra solución: We optimize the angle and speed to ensure the belt conveyor for discharge conveyor tasks clears the machine outlet instantly, preventing jams.

Hygiene & Raw Food Handling

Belt Conveyor for Food Packaging (Hygiene Focus) When handling raw protein (meat, poultry, seafood) or ready-to-eat foods, hygiene is non-negotiable. Easy clean belt conveyor applications utilize specific materials like food-grade PU or Cinturones modulares de plástico. These systems are designed with open frames and tool-less disassembly features.

Key Benefit: withstands high-pressure washdowns and prevents bacterial growth.

Nuestra solución: Our modular conveyors are the standard belt conveyor for food packaging, offering durability against oil, water, and abrasion.

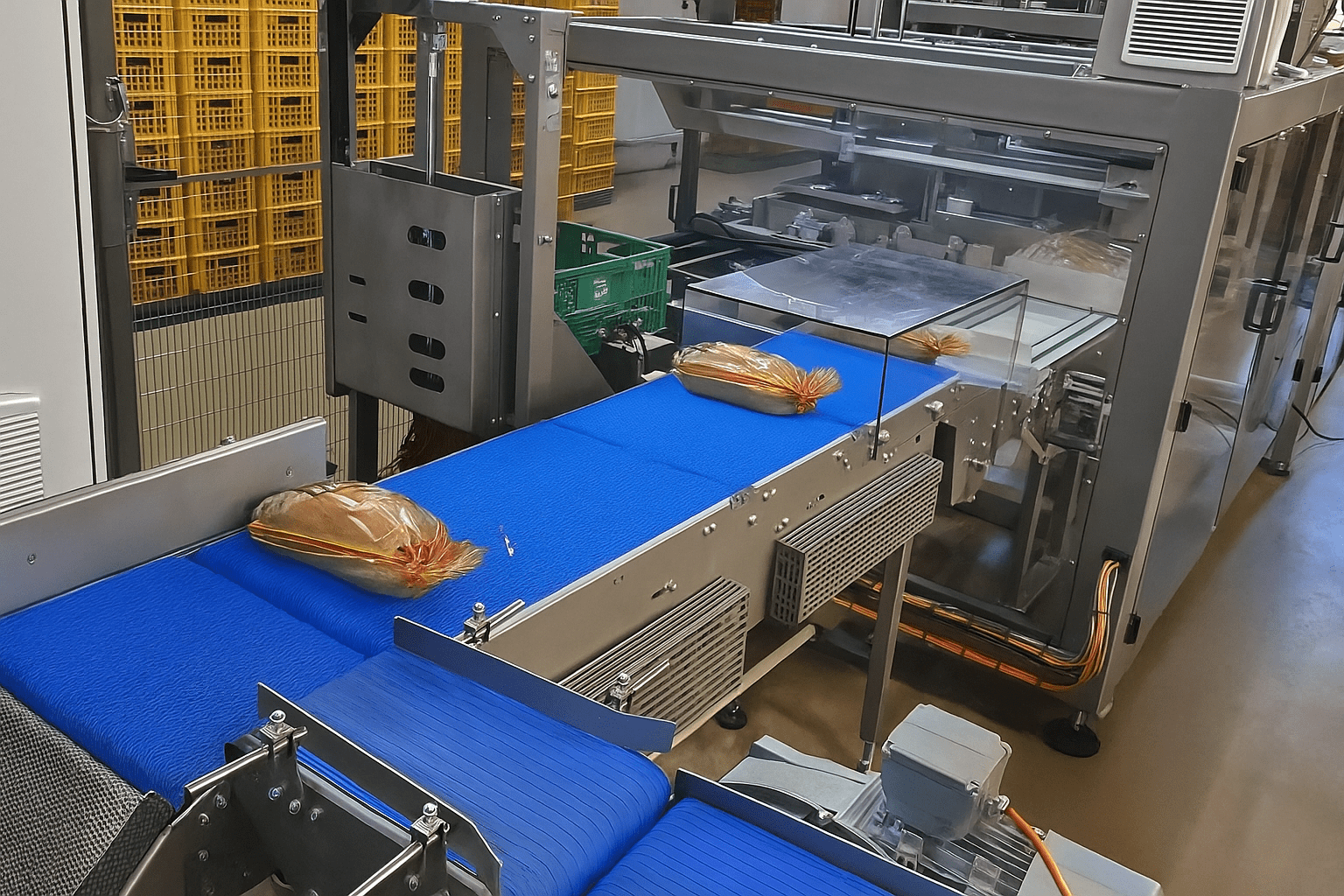

Product Transfer & Integration

Belt Conveyor for Product Transfer Between Machines Seamless connection is the belt conveyor role in packaging lines. Whether bridging the gap between a Multihead Weigher and a platform, or feeding a metal detector, stable transfer is crucial. A belt conveyor for packaging machines must offer precise speed control to match the throughput of upstream and downstream equipment, preventing bottlenecks.

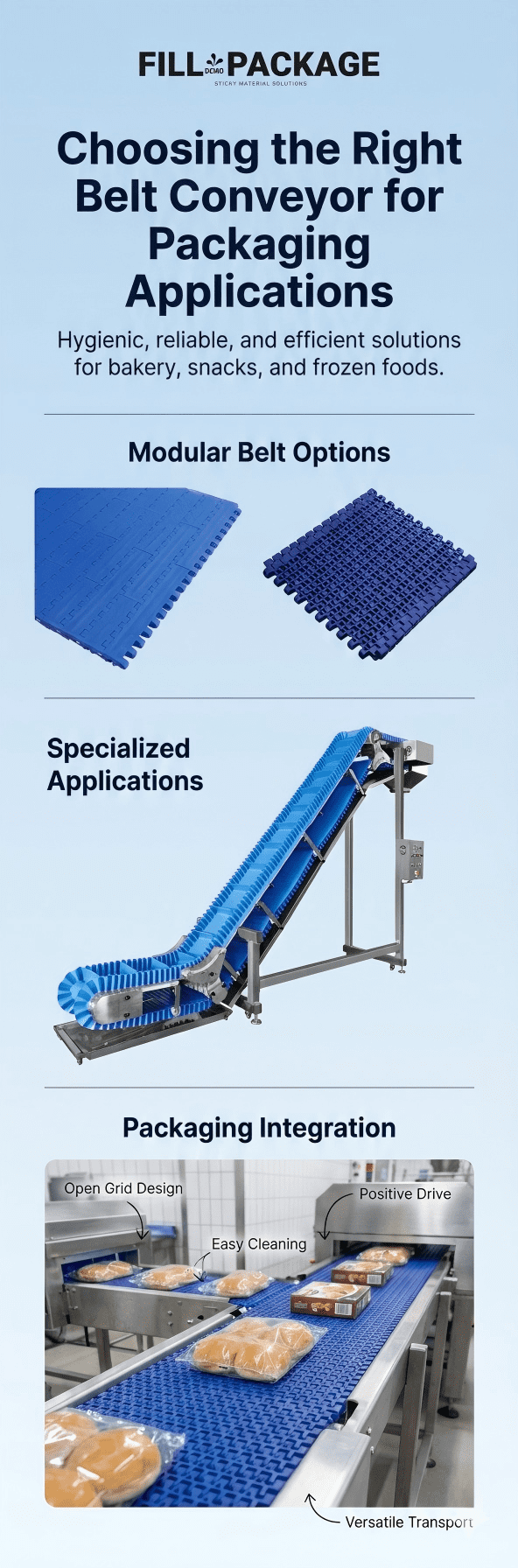

Choosing the Right Belt Conveyor for Packaging Applications

Not sure which type fits your line? Here is a quick guide on how to use belt conveyors in packaging effectively:

For Finished Bags/Boxes: Elige uno Transportador de banda plana o Incline Belt. Economic and efficient for dry, packaged goods.

For Raw/Sticky Food: Elige uno Transportador de banda modular. The best easy clean belt conveyor application for washdown environments.

For Elevation Changes: Elige uno Cleated or Z-Type Conveyor. Essential for lifting products in limited spaces.

Quick Selection Guide: Matching Conveyor to Application

Application Stage | Common Challenge | Recommended Solution |

Bulk Infeed | Spillage of raw product | Trough Belt or Flat Belt with High Guides |

Transfer | Maintaining product spacing | Standard Flat or Modular Belt |

Elevation (Incline) | Product sliding or rolling back | Cleated Belt or Rough-Top Belt |

Inspection (QC) | Inaccurate readings | Stable Flat Belt with Integrated Rejector |

Almacenamiento en búfer | Line stoppages causing jams | Accumulation Conveyor |

Case Handling | Heavy, bulky boxes | Heavy-Duty Belt or Roller Conveyor |

Washdown/Sanitary | Bacteria growth, cleaning difficulty | Stainless Steel Modular or Solid TPU Belt |

Productos relacionados

Blogs :

1.Why Belt Conveyor Applications Matter in Packaging Lines: The Key to Stability

2.Common Belt Conveyor Applications in Automated Packaging Systems

3.How Belt Conveyor Applications Affect Packaging Line Efficiency

Partner with Fill Package for Your Application

Belt conveyors are versatile and used throughout packaging lines for various tasks. Common applications include product transfer between machines (e.g., from weigher to bagger), feeding products into a machine, and acting as a discharge conveyor to elevate finished bags to a rotary table. They are also essential for manual packing stations and inspection areas.

Packed/Dry Food: A standard PU/PVC Flat Belt Conveyor is cost-effective and sufficient.

Raw/Sticky Food (Meat, Poultry): Te recomendamos Plastic Modular Belt Conveyors. These are designed for easy clean belt conveyor applications, allowing water and debris to drain through. They withstand high-pressure washdowns and are FDA-approved.

A belt conveyor for take away applications (often called an Incline or Take-Away Conveyor) is typically placed under the outlet of a VFFS packaging machine. To prevent the finished bags from sliding back down, we use cleated belts (belts with baffles) or high-friction rough-top belts to securely transport the bags up to a packing table or check weigher.

When choosing a belt conveyor for packaging applications, consider three things:

Product State: Is it raw, sticky, or packaged? (Determines belt material: Modular vs. PU).

Path: Do you need to go up (Incline), turn (Curved), or go straight?

Integración: Does the speed need to match a specific máquina de embalaje? (We offer variable speed drives for precise control).

Yes. Our conveyors are engineered to play a key role in packaging lines. We design them with adjustable heights and standard electrical interfaces to seamlessly connect with Multihead Weighers, Vertical Form Fill Seal (VFFS) machines, and Metal Detectors, ensuring a smooth product transfer flow without bottlenecks.