Integrated Conveyor Systems for Packaging Lines

Don’t let poor material flow bottleneck your packaging line. We engineer intelligent Sistemas transportadores that seamlessly connect your VFFS, Multihead Weighers, and Packing Stations.

Don't Let Poor Material Flow Bottleneck Your Packaging Line

Your packaging line is only as fast as its slowest point. When material flow is inconsistent, your multihead weigher starves, your VFFS machine waits, and your case packer sits idle. The result is lost production, frustrated operators, and missed delivery targets. An integrated conveyor system is not just about moving product from Point A to Point B. It is about orchestrating a seamless, synchronized flow of materials across every stage of your process, ensuring that each machine receives exactly what it needs, precisely when it needs it.

At Fill Package, we design and integrate complete conveyor systems that eliminate bottlenecks, reduce downtime, and maximize your Overall Equipment Effectiveness (OEE). Our approach combines the right conveying technology for each stage of your line with intelligent controls that adapt to real-time production demands. Whether you are handling delicate potato chips, sticky cheese, abrasive powders, or irregularly shaped components, we have the expertise and equipment to keep your line running smoothly.

Understanding Material Flow Dynamics in Packaging

Material flow is the science of moving products efficiently through a production environment. In packaging, this means maintaining a consistent, controlled, and gentle transfer of product from bulk storage through weighing, filling, and final packaging. Poor material flow creates three critical problems. First, it causes starvation, where downstream equipment waits for product, reducing throughput. Second, it leads to flooding, where too much product overwhelms a machine, causing jams and waste. Third, it results in product damage, as rough handling breaks, crushes, or degrades the product quality.

A well-designed conveyor system solves these problems by balancing speed, capacity, and control at every transfer point. It uses buffering to absorb variations in upstream supply and intelligent sensors to communicate with downstream equipment. The outcome is a production line that operates at a steady, predictable pace, maximizing both speed and quality.

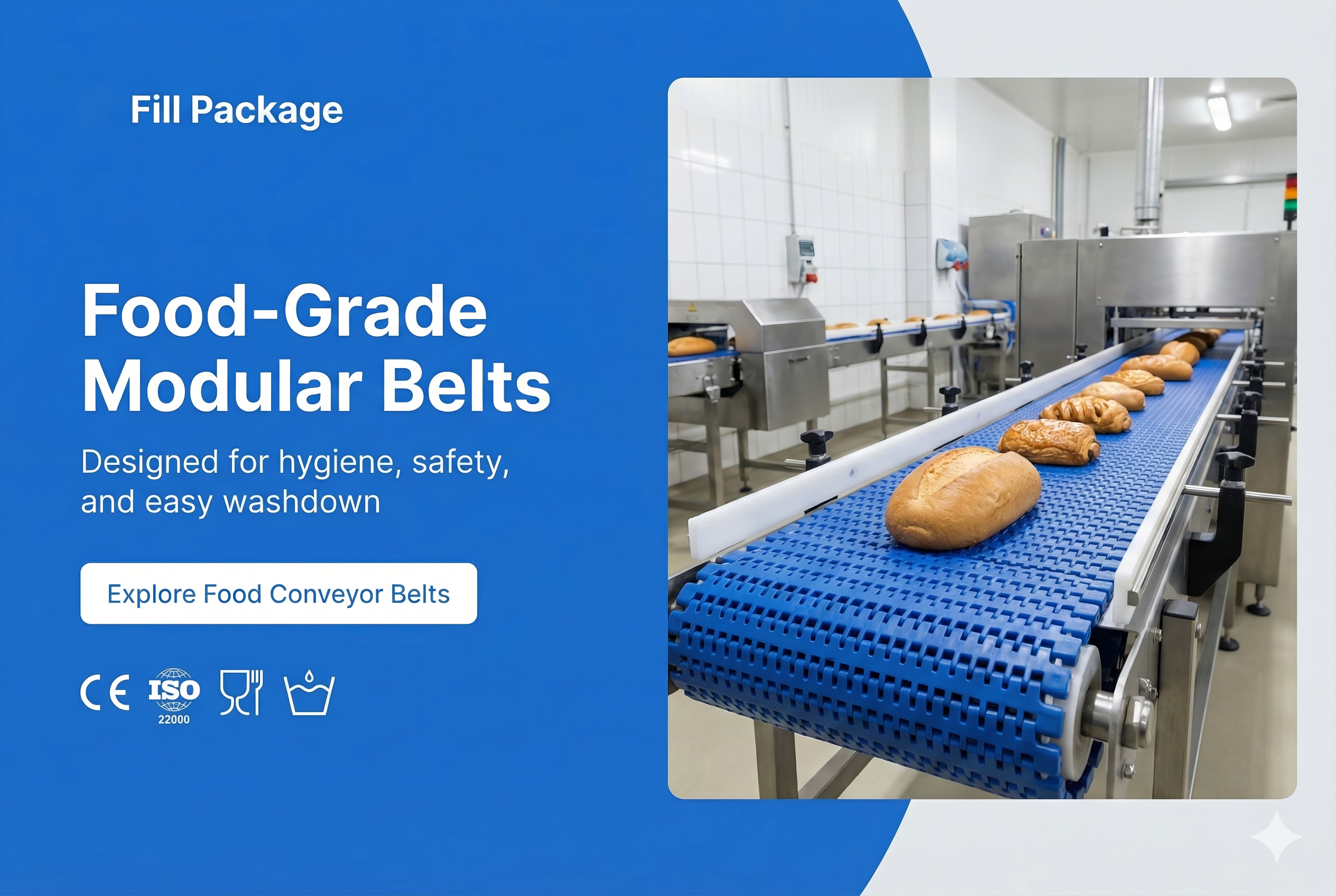

Belt Conveyor Systems – The Foundation of Your Line

Belt conveyor systems form the backbone of most packaging lines, providing reliable horizontal transport of products between processing stages. They are versatile, cost-effective, and available in a wide range of configurations to suit different product types and layouts. Our portfolio includes flat belt conveyors for general transport, modular belt conveyors for heavy loads and flexible layouts, inclined and decline conveyors for elevation changes, curved belt conveyors for navigating corners, cleated belts for steep inclines, and stainless steel food-grade conveyors for hygienic washdown environments.

While belt conveyors are essential, they represent just one component of a complete system. For an in-depth exploration of each belt type, their technical specifications, and detailed application guidance, please visit our dedicated Belt Conveyor page.

Feeding & Incline Conveying Systems – The Heartbeat of Your Line

While belt conveyors handle the horizontal transport, feeding and incline conveying systems are the critical heartbeat of your packaging line. They precisely dose, elevate, and transfer materials between processes, ensuring a smooth, consistent, and controlled flow. Getting this stage right is essential for preventing starvation at the weigher or over-flooding at the VFFS machine, directly impacting your Overall Equipment Effectiveness (OEE).

Our feeding systems are engineered to handle a diverse range of product characteristics, from delicate, friable snacks to sticky, wet, or abrasive powders. We focus on gentle handling, precise metering, and hygienic design to protect your product integrity and maximize uptime.

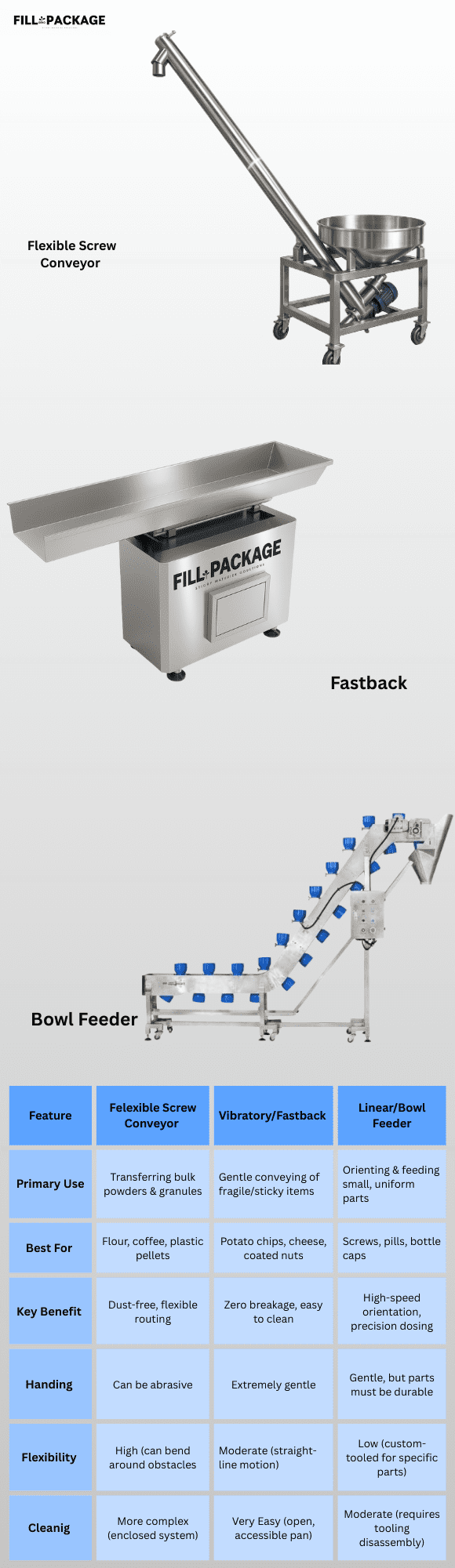

Flexible Screw Conveyor: The Versatile Workhorse for Powders and Granules

The Flexible Screw Conveyor, often called an auger conveyor, is a highly versatile and economical solution for transferring powders, granules, and other bulk solids. It consists of a spiral-shaped screw rotating within a sealed tube, which moves material from the inlet to the discharge point. Its enclosed design makes it an excellent choice for applications where dust containment and hygiene are paramount.

This system excels when handling powders such as flour, spices, milk powder, chemical additives, and pigments. It is equally effective with granules like coffee beans, plastic pellets, seeds, and small grains. The key requirement is that the product should be non-friable, meaning it is not easily broken or damaged during the conveying process.

The core advantages of the flexible screw conveyor are compelling. First, it offers dust-tight operation. The enclosed tube prevents product leakage and airborne dust, ensuring a clean and safe working environment. Second, it provides flexible routing. The flexible tube can be routed around obstacles, over long distances, and at various angles, offering significant layout versatility. Third, it requires low maintenance. With only one moving part—the screw—these conveyors are simple, reliable, and require minimal maintenance. Finally, it is cost-effective, offering a lower initial investment compared to other conveying systems like pneumatic or aeromechanical conveyors.

Vibratory & Fastback Conveyor: Gentle Handling for Delicate & Sticky Products

Vibratory Conveyors, particularly the innovative Fastback horizontal motion conveyor, are the gold standard for handling delicate, sticky, or easily segregated products. Instead of using aggressive vibration, the Fastback system uses a patented slow-forward, quick-back motion. This allows the product to gently glide along the pan without bouncing, breaking, or losing coatings.

The best applications for this technology include fragile products like potato chips, cookies, crackers, nuts, and confectionery. It is ideal for coated and seasoned items, preventing loss of expensive coatings and ensuring even seasoning distribution. Sticky products such as fresh-cut produce, cheese, and gummy candies that would clump on a standard belt also benefit greatly. Additionally, it maintains the integrity of product blends, ensuring pre-mixed ingredients remain perfectly combined without segregation.

The advantages are clear. First, there is zero breakage. The gentle horizontal motion eliminates product damage, preserving quality and reducing waste. Second, there is no segregation. Blended products remain perfectly mixed from the start of the line to the end. Third, it is easy to clean. The smooth, open pan has no crevices or moving parts in the product zone, allowing for quick and thorough sanitation. Finally, it offers instantaneous stop-start capability. The precise motion control allows for accurate and immediate stopping of product flow, which is crucial for feeding multihead weighers.

Linear & Bowl Vibration Feeder: Precision Dosing for Small Components

Linear and Bowl Vibration Feeders are designed for the precise orientation and metered feeding of small, uniform components. A Bowl Feeder uses a vibratory spiral track to separate and orient parts, delivering them in a consistent, single-file line. A Linear Feeder then transports these oriented parts to the next stage, such as a counting machine or assembly station.

These systems are best suited for small hardware like screws, nuts, bolts, and washers for kitting operations. They are also ideal for pharmaceuticals, including pills, tablets, and capsules for bottling lines. In electronics manufacturing, they handle small components for automated assembly. In packaging, they feed bottle caps, lids, or scoops with precision.

The core advantages include high-speed orientation, which automatically orients irregularly shaped parts into a consistent position for downstream automation. They provide accurate metering, offering a reliable, controllable, and precise flow rate that prevents jams and ensures accuracy. They deliver automated efficiency, dramatically reducing the need for manual labor in parts handling and sorting, thereby increasing throughput. Finally, they offer a compact footprint, providing a high-density feeding solution within a minimal space.

How to Select the Right Conveyor System – A Step-by-Step Guide

Choosing the optimal conveyor system is a strategic decision that impacts your entire production line’s efficiency. A mismatched conveyor can lead to product damage, bottlenecks, and excessive maintenance. Use this guide to navigate the selection process and build a material handling system that is perfectly aligned with your products, processes, and goals.

Step 1: Analyze Your Product Characteristics

The product itself is the most important factor. Start by examining the form and size. Is it a fine powder, a uniform granule, a delicate solid, or an irregular-shaped item? Powders and granules are best handled by a Flexible Screw Conveyor. Small, uniform parts are ideal for a Bowl or Linear Feeder. Most other items work well with a Belt or Vibratory Conveyor.

Next, consider fragility. Is the product easily broken, crumbled, or bruised? Does it have an expensive coating? Highly fragile or coated products require a Vibratory Fastback Conveyor to prevent breakage and coating loss. Moderately durable products can be handled by a standard Belt Conveyor.

Finally, assess flowability. Is the product free-flowing, sticky, or prone to clumping? Sticky or wet products benefit from a Vibratory Fastback Conveyor, which prevents sticking to the surface. Free-flowing products work well with a Belt or Screw Conveyor.

Step 2: Define the Process Requirements

Once you understand the product, consider the conveyor’s function within your line. For bulk transfer, a Belt or Screw Conveyor is appropriate. For elevation, an Incline Belt or Bucket Elevator is needed. For precision dosing or feeding, a Vibratory or Screw Feeder is the right choice. For orientation and sorting, a Bowl Feeder is essential.

You must also define the required throughput. What is the target volume or weight per hour? This will determine the necessary conveyor width, speed, and motor size. Additionally, evaluate the environment. In washdown or hygienic settings, a Stainless Steel Belt or Vibratory Conveyor is required. In dusty environments, an Enclosed Flexible Screw Conveyor is the best option.

Step 3: Map the Physical Layout

Finally, evaluate the physical space and path. Consider the path the product must take. Does it need to move in a straight line, go around corners, or change elevation? Straight-line movement is suited for Flat Belt, Vibratory, or Screw Conveyors. Corners require a Curved Belt Conveyor. Inclines or declines need an Incline or Decline Belt, or a Flexible Screw Conveyor.

Also consider the available footprint. How much floor space is available? In limited space, a Flexible Screw Conveyor can be routed vertically and around obstacles. Alternatively, a Bucket Elevator provides efficient vertical lift in a compact footprint.

By systematically working through these three steps, you can confidently identify the most effective and efficient conveyor technology for each stage of your packaging process. Our engineering team is always available to provide expert consultation and design a fully integrated solution tailored to your unique needs.

System Integration Capabilities – The Intelligence Behind the Flow

A conveyor system is more than a collection of individual machines. It is an intelligent, coordinated network that responds to real-time production demands. Our integration capabilities ensure that every conveyor, sensor, and control point works together seamlessly, creating a unified production line that maximizes efficiency and minimizes downtime.

PLC-Based Control Systems

We design and program custom PLC (Programmable Logic Controller) systems that serve as the brain of your conveyor network. These systems monitor sensor inputs, manage motor speeds, and coordinate start-stop sequences across multiple conveyors. The result is a line that automatically adjusts to changing conditions, preventing jams and ensuring smooth product flow.

Equipment Communication & Handshaking

Our conveyor systems are designed to communicate with your existing packaging machinery, including multihead weighers, VFFS baggers, and case packers. We use standard industry protocols to create electronic handshakes, ensuring that conveyors start and stop based on signals from upstream or downstream equipment. This coordination eliminates product waste and prevents machine collisions.

Intelligent Buffering & Accumulation

To handle brief stoppages or variations in production speed, we incorporate accumulation tables and buffering conveyors into the system. These sections temporarily hold a buffer of product, allowing upstream equipment to continue running even when downstream equipment is momentarily stopped. When the downstream machine comes back online, the buffer is automatically cleared, maintaining overall line efficiency.

Hygienic Design for Food Safety

For food applications, hygienic design is non-negotiable. Our stainless steel conveyors feature open-frame construction to eliminate hidden areas where bacteria can grow, tool-less removal of belts and components for easy cleaning, and smooth surfaces free of crevices. All materials are food-grade, and the systems are designed to withstand high-pressure washdowns.

Why Choose Fill Package for Your Conveyor System Integration?

Proven Expertise in Packaging Lines: We specialize in packaging automation, not just conveyors. We understand how material flow impacts weighing accuracy, filling speed, and overall line performance.

Customized Solutions, Not Off-the-Shelf Products: Every line is different. We design each system to match your specific products, processes, and facility layout.

Seamless Integration with Existing Equipment: Our systems are built to work with your current machinery, whether it is a pesadora multicabezal, Máquina VFFS, or case packer.

Focus on Hygienic Design: For food and pharmaceutical applications, we prioritize easy cleaning, food-grade materials, and compliance with industry standards.

Reliable Support & Service: We provide comprehensive installation, training, and ongoing technical support to keep your line running smoothly.

Eficiencia energética: Our control systems can be programmed to run conveyors only when product is present, significantly reducing electricity usage during production gaps.

Fast Lead Times: We maintain stock of common components and work efficiently to minimize project timelines.

Producto relacionado

Related Blogs :

1.Why Conveyor Systems Dictate Your Packaging Line Output: The Hidden Killer of OEE

2.How to Design an Efficient Conveyor System for Packaging Lines: An Engineering Guide

3.Conveyor System vs. Individual Conveyors: What’s the Difference?

Frequently Asked Questions (FAQ) about Conveyor System Integration

A single “conveyor” is a piece of equipment that moves materials from one point to another, such as a belt conveyor or a screw conveyor. A “conveyor system,” on the other hand, is a fully integrated solution that often involves multiple types of conveyors working together. It also includes the necessary controls, sensors, and logic (like PLCs) to manage the flow of product across an entire packaging line. A system is designed to solve a complete material handling challenge, not just move a product along a single path.

Smooth transfers are critical to prevent product damage and jams. We achieve this through careful engineering of the transfer points. This can involve using small-radius nose bars for tight transfers of small products, powered transfer plates, or ensuring the discharge of one conveyor is positioned perfectly over the receiving end of the next. For delicate products, we use vibratory feeders to gently spread the product onto the next conveyor, ensuring it does not drop and break.

Absolutely. Our primary expertise lies in system integration. We design our conveyor control systems to communicate seamlessly with other machinery, such as multihead weighers, VFFS baggers, and case packers. We use standard industry protocols and can customize the electronic handshakes to ensure our conveyors start and stop based on the signals from your upstream or downstream equipment, creating a truly unified production line.

OEE stands for Overall Equipment Effectiveness, a key metric for measuring manufacturing productivity. It multiplies Availability (runtime), Performance (speed), and Quality (good products). A well-designed conveyor system directly boosts all three. It improves Availability by reducing jams and downtime. It enhances Performance by consistently feeding product at the optimal rate. And it increases Quality by gently handling products to prevent damage and waste.

Product accumulation is essential for keeping the line running smoothly, especially when there is a brief stoppage downstream. We can incorporate accumulation tables or buffering conveyors (often using low-friction modular belts) into the system. These sections can temporarily hold a buffer of product, allowing the upstream equipment to continue running for a short period. When the downstream machine comes back online, the buffer is automatically cleared.

For food applications, hygienic design is non-negotiable. Our stainless steel conveyors are built with this in mind. Key features include open-frame construction to eliminate hidden areas where bacteria can grow, tool-less removal of belts and components for easy cleaning, and surfaces that are smooth and free of crevices. All materials are food-grade, and the system is designed to withstand high-pressure washdowns.

Energy consumption depends on the total length, load, and number of motors in the system. However, we prioritize energy efficiency in our designs. We use high-efficiency motors and gearboxes. More importantly, our control systems can be programmed to run conveyors only when product is present (run-on-demand), significantly reducing electricity usage during gaps in production compared to systems that run continuously.

We design our systems for low maintenance. The most common tasks are periodic inspection of belt tension and tracking, checking gearbox lubrication, and ensuring sensors are clean. For our Fastback vibratory conveyors, there are virtually no moving parts in the product zone, making them extremely low-maintenance. We provide a detailed maintenance schedule and manual with every system we deliver.

This is a common challenge, especially with mixes of different-sized particles (like a nut and raisin mix). The best solution for this is a Fastback horizontal motion conveyor. Its gentle, non-vibratory gliding action moves the entire product bed as one, ensuring the mix ratio remains consistent from the beginning of the line to the package.

Lead time varies depending on the complexity of the system. A simple, single conveyor might be ready in a few weeks. A large, multi-conveyor integrated system with custom controls can take several months. The process involves a detailed design and approval phase before manufacturing begins. We work closely with you to establish a clear timeline from the outset and keep you updated throughout the project.

Ready to Optimize Your Material Flow?

Contact our engineering team today to discuss your specific conveyor system needs. We will work with you to design a solution that maximizes efficiency, protects product quality, and integrates seamlessly with your existing packaging line.