Băng tải chuyển động ngang FASTBACK

Nhẹ nhàng, Đáng tin cậy, Mang tính cách mạng

Băng tải FASTBACK là gì?

Tổng quan về sản phẩm

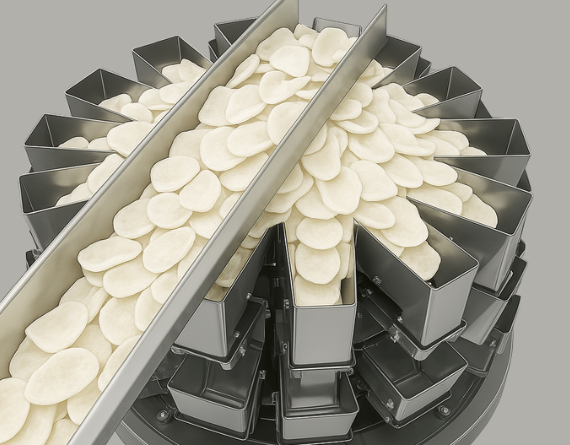

Băng tải chuyển động ngang FASTBACK, được phát triển bởi Heat and Control, là một giải pháp vận chuyển mang tính cách mạng, đại diện cho đỉnh cao của công nghệ vận chuyển công nghiệp hiện đại. Sử dụng các cải tiến được cấp bằng sáng chế, băng tải này mang đến khả năng xử lý sản phẩm nhẹ nhàng, hiệu quả và đáng tin cậy cho các ngành chế biến thực phẩm, đóng gói và xử lý vật liệu.

Định nghĩa sản phẩm

Băng tải chuyển động ngang FASTBACK là hệ thống vận chuyển tiên tiến với công nghệ chuyển đổi chuyển động tròn sang chuyển động thẳng đã được cấp bằng sáng chế. Chuyển động ngang chậm về phía trước và nhanh về phía sau đặc trưng của nó đảm bảo vận chuyển nhẹ nhàng các sản phẩm mỏng manh, dễ vỡ và được phủ lớp bảo vệ, giảm đáng kể hư hỏng sản phẩm và đảm bảo tính toàn vẹn của sản phẩm.

Các tính năng chính:

- Xử lý sản phẩm nhẹ nhàng

- Giảm thiểu sản phẩm bị vỡ

- Cải thiện khả năng giữ lớp phủ

Công nghệ chuyển động độc đáo:

Sử dụng chuyển động tiến chậm, lùi nhanh, sản phẩm di chuyển nhẹ nhàng về phía trước mà không bị hư hại, giảm thiểu đáng kể tình trạng thất thoát sản phẩm.

Đổi mới kỹ thuật

Băng tải FASTBACK được giới thiệu vào năm 1995 và liên tục phát triển với hơn 30 bằng sáng chế toàn cầu.

QUAY LẠI NHANH 4.0:

Mẫu máy mới nhất này cung cấp tốc độ, tính linh hoạt và độ tin cậy cao hơn, trở thành chuẩn mực cho ngành công nghiệp đồ ăn nhẹ trên toàn thế giới, bao gồm cả sản lượng đáng kể tại Trung Quốc.

Lợi ích với băng tải của chúng tôi

Giảm thiểu hư hỏng sản phẩm so với băng tải rung truyền thống.

Bảo vệ lớp phủ mỏng manh và hương liệu, giảm thiểu thất thoát.

Thép không gỉ dễ vệ sinh, đáp ứng các tiêu chuẩn vệ sinh nghiêm ngặt.

Thiết kế đơn giản hơn với 70% có ít bộ phận chuyển động hơn.

Nguyên lý hoạt động

Cơ chế chuyển động cơ bản:

Chuyển động chậm về phía trước, nhanh về phía sau giúp vận chuyển sản phẩm một cách nhẹ nhàng về phía trước.

Chuyển đổi chuyển động tròn sang chuyển động thẳng:

Công nghệ chuyển đổi tiên tiến cho hoạt động chính xác và đáng tin cậy hơn.

Kiểm soát ma sát:

Quản lý ma sát được tối ưu hóa đảm bảo chuyển động trơn tru mà không làm sản phẩm bị trượt ngược.

Chống rung:

Chuyển động ngang được kiểm soát làm giảm đáng kể độ rung.

Kiểm soát tốc độ và lưu lượng:

Điều chỉnh tốc độ thay đổi để tối ưu hóa lưu lượng và phân phối.

Tối ưu hóa năng lượng:

Chuyển động hiệu quả cao giúp giảm tổng mức tiêu thụ năng lượng.

Thiết bị tương thích

- Hệ thống cân: Máy cân nhiều đầu và kiểm tra để đóng gói chính xác.

- Thiết bị đóng gói: Máy tạo hình-đổ-niêm phong dạng đứng và ngang.

- Hệ thống gia vị và phủ: Hệ thống gia vị Revolution trên tàu và trong thùng.

- Thiết bị trộn và phân phối: Trộn hiệu quả và phân phối sản phẩm chính xác.

- Thiết bị kiểm tra và phân loại: Máy dò kim loại tích hợp, tia X và kiểm tra trực quan.

- Vệ sinh và vệ sinh: Khả năng tương thích với CIP và làm sạch áp suất cao.

Thông số kỹ thuật

Dung tích: Lên đến 60.000 lbs/giờ.

Tốc độ: Có thể điều chỉnh 5-40 ft/phút.

Vật liệu: Thép không gỉ (304/316).

Quyền lực: Ba pha 380/480V.

Cách chọn mẫu FASTBACK phù hợp

Việc lựa chọn băng tải FASTBACK phù hợp là chìa khóa để tối đa hóa hiệu quả và hiệu suất. Dưới đây là hướng dẫn đơn giản giúp bạn chọn được mẫu băng tải hoàn hảo:

Hiểu rõ sản phẩm của bạn

Hãy nghĩ đến sản phẩm của bạn trước. Các mặt hàng dễ vỡ như đồ ăn nhẹ, bánh quy hoặc kẹo cần được xử lý nhẹ nhàng, vì vậy băng tải FASTBACK là một lựa chọn tuyệt vời. Ngoài ra, hãy cân nhắc kích thước, trọng lượng sản phẩm và các tính năng đặc biệt như lớp phủ hoặc gia vị để phù hợp hoàn hảo với băng tải của bạn.

Kiểm tra năng lực của bạn

Tính toán lượng sản phẩm bạn sẽ xử lý. Băng tải FASTBACK có thể xử lý nhiều công suất khác nhau, lên đến 60.000 pound/giờ. Hãy chọn loại băng tải phù hợp với nhu cầu sản xuất thông thường và cao điểm của bạn để tránh chậm trễ.

Đo không gian của bạn

Hãy kiểm tra kỹ không gian hiện có của bạn. Băng tải FASTBACK có thiết kế nhỏ gọn và dạng mô-đun, vì vậy việc tìm kiếm sản phẩm phù hợp với bố trí nhà máy của bạn rất dễ dàng. Hãy đảm bảo chọn kích thước phù hợp với không gian hiện có.

Vấn đề vệ sinh

Chế biến và đóng gói thực phẩm đòi hỏi tiêu chuẩn vệ sinh cao. Băng tải FASTBACK có bề mặt thép không gỉ dễ vệ sinh. Hãy chọn loại có bề mặt liền mạch và các bộ phận dễ tiếp cận để dễ dàng vệ sinh và bảo trì.

Tích hợp thiết bị

Đảm bảo băng tải FASTBACK mới của bạn kết nối liền mạch với các thiết bị hiện có, chẳng hạn như máy cân, máy đóng gói và dụng cụ kiểm tra. Sự tích hợp này sẽ tăng hiệu quả và giảm thời gian cũng như chi phí lắp đặt.

Ứng dụng

Ngành chế biến thực phẩm:

- Đồ ăn nhẹ và khoai tây chiên: Giảm đáng kể tỷ lệ vỡ 60%.

- Sản phẩm bánh mì: Thích hợp cho bánh quy, bánh quy giòn và bánh quy giòn.

- Kẹo và bánh kẹo: Bảo vệ lớp phủ trang trí.

Ngành thực phẩm đông lạnh:

Đảm bảo tính toàn vẹn của rau củ, trái cây và các sản phẩm thịt đông lạnh, đặc biệt lý tưởng cho khoai tây chiên đông lạnh.

Ngành công nghiệp thực phẩm cho thú cưng:

Duy trì chất lượng dinh dưỡng và độ bao phủ của thức ăn cho vật nuôi.

Chế biến ngũ cốc:

Thích hợp cho ngũ cốc, yến mạch và ngũ cốc dạng mảnh.

Chế biến thịt và gia cầm:

Hoàn toàn phù hợp cho các loại thịt thay thế và thịt chế biến.

Bảo trì và Chăm sóc

Bảo trì tốt sẽ giúp băng tải FASTBACK của bạn hoạt động trơn tru và hiệu quả. Dưới đây là một số mẹo đơn giản bạn có thể áp dụng:

Vệ sinh hàng ngày

Vệ sinh thường xuyên sau mỗi ca làm việc để loại bỏ cặn sản phẩm và bụi bẩn. Sử dụng chất tẩy rửa phù hợp dành riêng cho bề mặt thép không gỉ sẽ giúp băng tải luôn sạch sẽ và hợp vệ sinh.

Kiểm tra thường xuyên

Lên kế hoạch kiểm tra hàng tuần hoặc hàng tháng để phát hiện sớm các vấn đề tiềm ẩn. Thường xuyên kiểm tra dây đai, động cơ, ổ trục và bộ điều khiển để phát hiện dấu hiệu hao mòn hoặc hư hỏng. Phát hiện sớm đồng nghĩa với việc giảm thiểu sự cố bất ngờ và thời gian ngừng hoạt động.

Chăm sóc linh kiện

Mặc dù băng tải FASTBACK có ít bộ phận chuyển động hơn, nhưng việc bôi trơn các bộ phận cụ thể đôi khi có thể giúp duy trì hoạt động trơn tru. Luôn tuân thủ khuyến nghị của nhà sản xuất về chất bôi trơn và lịch trình.

Bảo trì phòng ngừa

Hãy chủ động kiểm tra và siết chặt các chốt, kiểm tra độ căng của dây đai và hiệu chuẩn hệ thống điều khiển thường xuyên. Bảo trì định kỳ giúp ngăn ngừa các sự cố bất ngờ và kéo dài tuổi thọ băng tải.

Đào tạo và Hồ sơ

Đảm bảo đội ngũ của bạn được đào tạo về vận hành, vệ sinh và xử lý sự cố băng tải FASTBACK. Lưu giữ hồ sơ bảo trì rõ ràng để bạn có thể theo dõi tình trạng băng tải và lên lịch bảo trì kịp thời.

Thực hiện các bước bảo trì đơn giản sau sẽ giúp băng tải FASTBACK của bạn luôn hiệu quả và đáng tin cậy trong nhiều năm tới.

Ưu điểm của gói điền

Tại FILL PACKAGE, chúng tôi tùy chỉnh từng băng tải FASTBACK để đáp ứng chính xác các tiêu chuẩn của bạn, đảm bảo tích hợp liền mạch vào dây chuyền sản xuất của bạn.

Chúng tôi cung cấp dịch vụ hỗ trợ cá nhân hóa tuyệt vời từ khâu thiết kế ban đầu cho đến lắp đặt và bảo trì liên tục, coi sự hài lòng của bạn là ưu tiên hàng đầu.

Sản phẩm liên quan

Các sản phẩm dễ vỡ và có lớp phủ như khoai tây chiên, kẹo và đồ đông lạnh.

Có, đáng kể là bằng cách loại bỏ các bộ phận chuyển động phức tạp.

Chắc chắn rồi, chúng rất hiệu quả trong việc bảo quản sản phẩm đông lạnh.

Kết cấu bằng thép không gỉ và thiết kế liền mạch giúp loại bỏ bụi bẩn tích tụ.

Có, thiết kế sáng tạo của nó làm giảm đáng kể mức tiêu thụ điện năng

Có. Hệ thống được chế tạo với chiều dài vượt quá 200 feet và chiều rộng chảo vượt quá 10 feet—xử lý khối lượng lớn và tải trọng tác động mạnh trong các ứng dụng đòi hỏi khắt khe.

Có. Hệ thống được chế tạo với chiều dài vượt quá 200 feet và chiều rộng chảo vượt quá 10 feet—xử lý khối lượng lớn và tải trọng tác động mạnh trong các ứng dụng đòi hỏi khắt khe.