En la producción industrial moderna, transportadores de banda Son equipos esenciales para la manipulación de materiales y desempeñan un papel crucial en numerosos sectores, desde el procesamiento de alimentos hasta la fabricación pesada, la minería y la logística de embalaje. Sin embargo, con la enorme variedad de productos y los diversos escenarios de aplicación, seleccionar el sistema de cinta transportadora más adecuado puede suponer un reto considerable para las empresas.

Esta guía ofrece información completa sobre los criterios de selección, las características técnicas, los problemas comunes y las soluciones prácticas de los sistemas de cintas transportadoras. Tanto si es nuevo en la tecnología de transportadores como si es un ingeniero experimentado que busca optimizar su sistema actual, esta guía le ofrece valiosos consejos para ayudarle a tomar decisiones.

Descripción general de los sistemas transportadores de banda

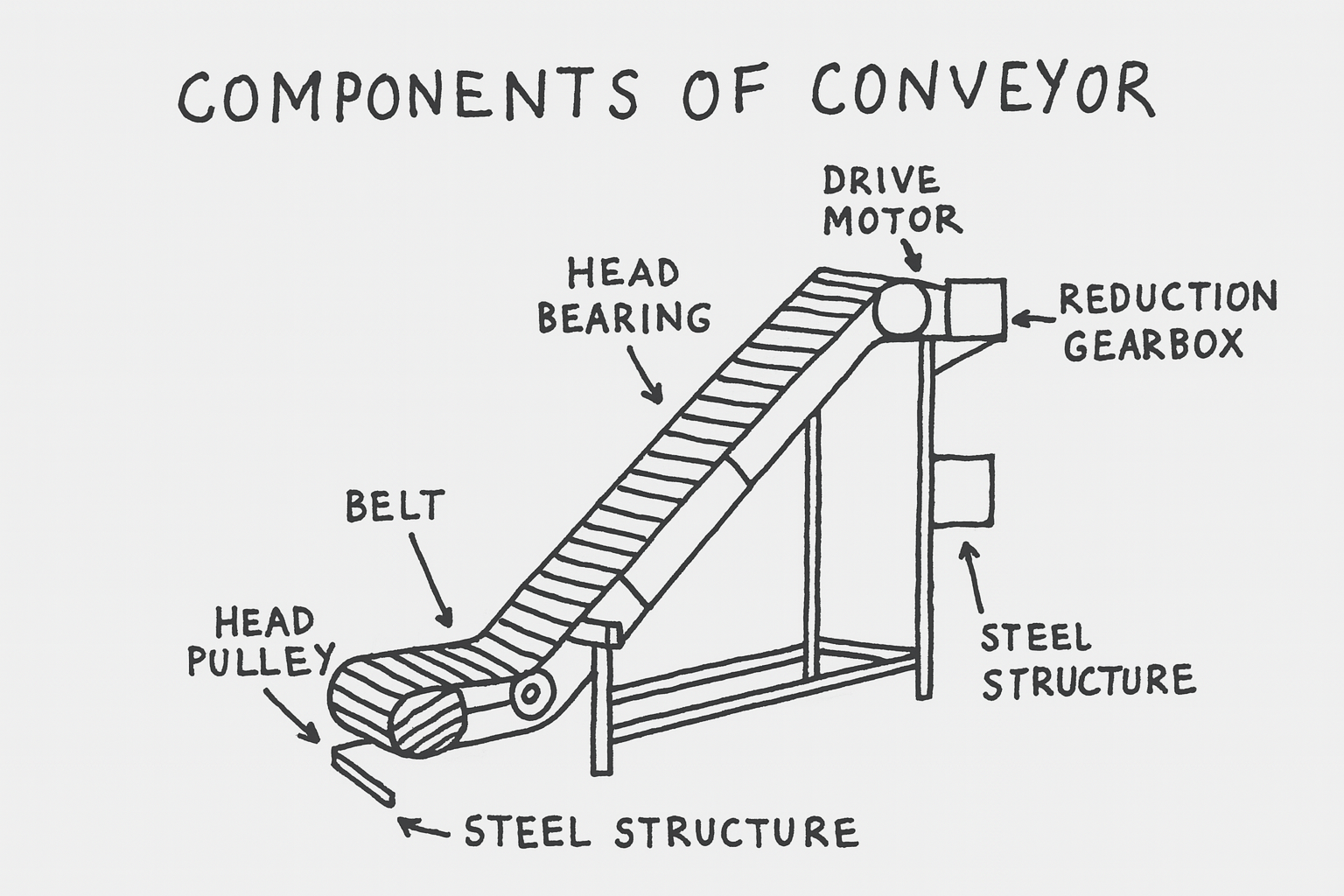

Una banda transportadora es un dispositivo de transporte continuo de materiales accionado por un motor que acciona tambores o ruedas dentadas para mover una banda transportadora, permitiendo el movimiento horizontal, inclinado o vertical. Sus componentes básicos incluyen la banda, el motor, la estructura de soporte, el tensor y el sistema de limpieza. En comparación con otros métodos de manipulación de materiales, las bandas transportadoras ofrecen ventajas significativas, como alta capacidad de transporte, funcionamiento suave, eficiencia energética y fácil mantenimiento.

Además, los sistemas de transporte modernos han evolucionado desde simples herramientas de transporte hasta soluciones logísticas integradas e inteligentes. Al integrarse con sistemas de control de automatización, redes de sensores y plataformas de análisis de datos, los transportadores modernos ofrecen posicionamiento preciso de materiales, control de flujo, monitoreo en tiempo real y capacidades de mantenimiento predictivo.

¿Está interesado en actualizar su sistema de manejo de materiales? Contáctanos ¡Hoy para discutir sus necesidades específicas!

Factores clave en la selección de transportadores de banda

La selección del sistema transportador de banda adecuado requiere una cuidadosa consideración de múltiples factores y condiciones de aplicación:

Características del producto

En primer lugar, el tamaño, el peso y las propiedades específicas del material del producto influyen significativamente en la selección del transportador, lo que afecta la estabilidad, la capacidad de carga y la durabilidad requerida. Las propiedades del material influyen considerablemente en el diseño del transportador. Los polvos requieren sellos herméticos y sistemas de limpieza; los sólidos requieren consideraciones de fricción superficial y desgaste; los líquidos exigen diseños a prueba de fugas. El manejo de polvos a menudo utiliza Transportadores de tornillo flexibles, Mientras que los sólidos dependen de correas de fricción o grapas. Los materiales corrosivos requieren opciones protectoras y resistentes a la corrosión, como... transportador de banda inclinada.

Requisitos del proceso

Además, el control adecuado de la orientación del producto y los métodos de carga efectivos deben adaptarse a sus procesos de producción específicos, garantizando un funcionamiento fluido y mínimas interrupciones.

Condiciones del entorno operativo

Además, evalúe las capacidades de inclinación, considere sistemas antirretroceso y seleccione materiales resistentes a las fluctuaciones de temperatura, la humedad y la posible corrosión.

Parámetros operativos

Por último, los sistemas de control de velocidad óptimos y la adaptabilidad a las condiciones ambientales ayudan a mantener una producción eficiente y la integridad del producto.

¿Necesita ayuda personalizada para seleccionar el sistema de transporte adecuado? ¡Contacte con nuestros expertos ahora!

Tipos y selección de materiales para cintas transportadoras

Diferentes materiales de cintas transportadoras se adaptan a requisitos ambientales y de aplicación específicos:

Materiales sintéticos

- Poliuretano (PU):Excelente para durabilidad, resistencia química y aplicaciones de grado alimenticio.

- Cloruro de polivinilo (PVC): Rentable, versátil y adecuado para usos industriales generales.

Materiales naturales

- Caucho natural:Ideal para aplicaciones pesadas debido a su excepcional elasticidad y resistencia al impacto.

- Reforzado con fibra natural:Ofrece alta estabilidad estructural y es adecuado para cargas pesadas.

Cinturones modulares de plástico

Conocido por su fácil mantenimiento, excelente higiene y flexibilidad, comúnmente utilizado en las industrias de procesamiento de alimentos, automotriz y electrónica.

Cinturones de funciones especiales

- Caucho de silicona:Proporciona resistencia a altas temperaturas y flexibilidad.

- reforzado con aramida:Ofrece una resistencia a la tracción superior para aplicaciones industriales extremas.

- Cinturones de calidad alimentaria:Garantiza el cumplimiento de estrictos estándares de higiene y el procesamiento seguro de alimentos.

Problemas comunes y soluciones

Limpieza y mantenimiento

El uso regular de sistemas de tensión de liberación rápida evita la sobrecarga del motor y simplifica el mantenimiento.

Desalineación de la correa

Además, la precisión en la alineación de los rodillos y la geometría del bastidor reducen significativamente las interrupciones operativas.

Seguridad alimentaria

Además, utilizamos materiales de grado alimenticio aprobados por la FDA y diseños higiénicos para minimizar los riesgos de contaminación.

Manipulación de productos

Además, la adaptación de los coeficientes de fricción y la optimización de las velocidades del transportador evitan la acumulación de producto y mejoran la estabilidad.

¿Tiene problemas con su sistema de transporte actual? Nuestro equipo puede ayudarle a identificar y resolver sus problemas. ¡Contáctenos ahora!

Parámetros técnicos y optimización del rendimiento

Las velocidades de operación suelen oscilar entre 2 y 50 metros por minuto, según las dimensiones, el peso y los requisitos específicos de producción del producto. Además, el ancho de la banda, generalmente estandarizado entre 100 mm y 800 mm, debe superar el ancho del producto en 20-301 TP3T para garantizar una estabilidad y una capacidad de manipulación adecuadas.

Consideraciones sobre el transporte inclinado

Los ángulos máximos de inclinación dependen de los coeficientes de fricción de la banda. Por lo tanto, las bandas especializadas o los sistemas de tacos integrados pueden facilitar la manipulación eficaz del material en pendientes más pronunciadas.

Integración de sistemas y optimización de transferencia

La integración eficiente del sistema, a través de espacios minimizados entre transportadores, mejora las transiciones fluidas de productos y reduce el tiempo de inactividad.

Gestión del mantenimiento y la vida útil

La implementación de ajustes regulares de tensión, un monitoreo preciso del estiramiento de la cinta transportadora y intervenciones de mantenimiento oportunas prolongan la vida útil del equipo y garantizan un rendimiento constante del sistema.

Conclusión y perspectivas

En conclusión, las bandas transportadoras siguen siendo indispensables para una manipulación de materiales eficiente y fiable en todas las industrias. Además, la innovación continua en la ciencia de los materiales, el diseño de transportadores y las tecnologías de integración promete mejoras adicionales en la versatilidad y la eficiencia operativa de los sistemas de transporte, lo que en última instancia ayuda a las empresas a lograr una mayor productividad y una mayor fiabilidad.

¿Listo para optimizar las operaciones de su transportador de banda? Hablemos sobre cómo podemos ayudarle a alcanzar el máximo rendimiento. ¡Contáctenos hoy mismo!