History

In 1972, the first multi-head combination scale was born in Japan, which solved the problems of large error and inefficiency in weighing by manual. With the continuous improvement and perfection of multi-head scale technology, its weighing accuracy and weighing speed and application has been significantly improved, and the multi-head weigher has gradually become an indispensable key equipment in the automatic packaging production line. With the automatic weighing and packaging of easy to flow solid food ,such like :snack food, fruit, etc, in order to satisfy the needs of the new food market, more and more weighing and packaging of different products are required,Among them,The weighing and packaging solution for sticky products has become a representative for distinguishing the technological differences among combination scale manufacturers. The screw feeder weigher was born for market requirement .

Work Objectives

Our manufacturing goal for the Screw Feeder Weigher is to enable sticky products to flow smoothly at every contact with the weigher,Ensure that there is no residue left on the weighing equipment throughout the entire weighing process to avoid affecting accuracy, and enable automated weighing of sticky products to increase production capacity. However, the linear vibratory plans are often prone to material blockage due to its shape, horizontal installation direction, and its can only work using vibration ,which is not strong enough to make sticky products to move.Adding screw pushers to on vibrating plate can perfectly solve the problem of material blocking,It is worth noting that,The shape, quantity, and configuration of screws used for different sticky products vary, and selecting the appropriate screw type is particularly important. For some materials, twin screws are more suitable.

Diversity

However, the screw linear plates only solves the problem of material blocking on the vibrating plate, but this does not mean that all the problems of material sticking or material blocking in contacted are solved, and our careful and professional design team had considered every external contact surface of the material carefully. The following are the different solutions we have made.

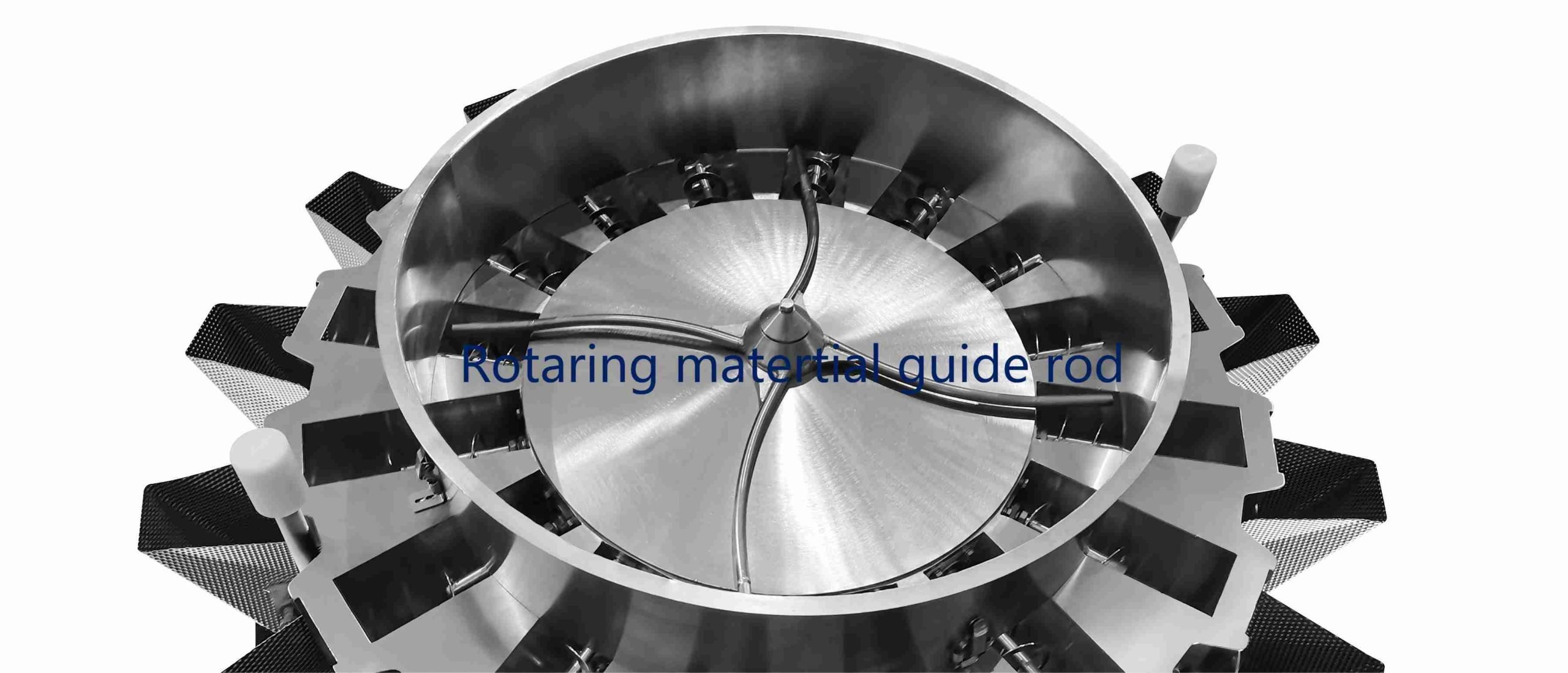

Main feeder plate :For sticky products ,our stanadrd main vibration plate is rotation with steep angle .which is convenient for sticky products to follow dorwn ,and a rotaring matertial guide rod is added on the main feeder plate to push the products into linear plate quickly and steadily.

Hoppers :The design of the hopper has taken into consideration all possible scenarios. The door opening direction has been changed from the standard vertical opening to a horizontal push-door opening, to prevent materials from sticking to the hopper door.

In addition, We have also pioneered a 180-degree rotating dumping grid hopper, which is made of stainless steel grid coated with Teflon, with 180 degree rotary discharge , to prevent materials from sticking to the weigh hopper door .effectively preventing most of the sticky materials from sticky on the hoppers.

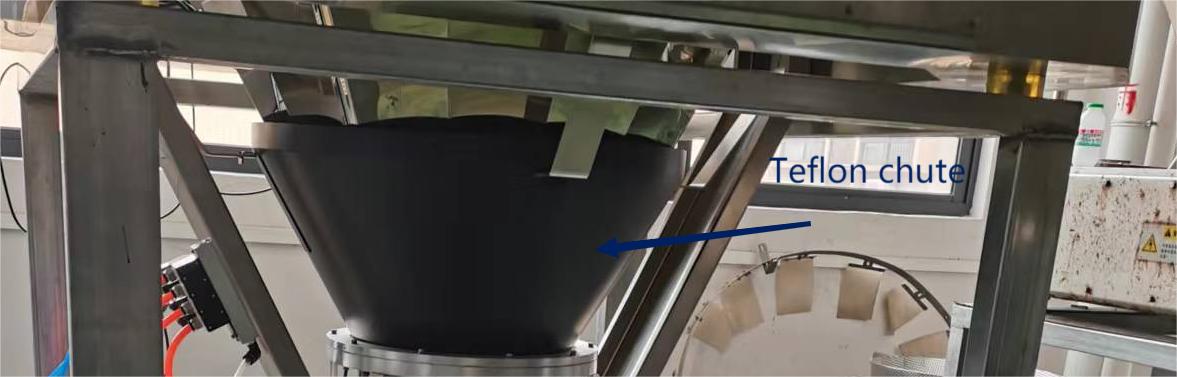

Chute :At the end of the process, chute generally has a steep angle , so the materials do not stick much during the fall. However, for some special products, we may add teflon on the chute or even use air-blow feeding.

Of course, all these mechanical modifications mentioned above vary depending on different materials and not all sticky products are suitable for these modifications. So our Screw feeder weigher is not the only one, there are various types.

Application

So far, screw feeder weighers are mainly used in the weighing and packaging of food products, commonly seen in fresh meat, cured meats, oily food products, ready-to-eat fast food, pickles, and more. In addition, they are widely used in production lines of liquid or semi-fluid food products such as fruit juice, beverages, condiments, salad dressings, and sauces, to ensure precise weighing and packaging for consistent product quality and packaging.

Screw material

The screw material used in the screw feeder weigher is made of stainless steel and has a spiral structure. The pitch, shape, and diameter of the screw are determined based on different products, The product on the multi-head weigher linear plate can be moved steadily to the hopper to realize automatic weighing.

Price

As the leading screw feeder multihead weighers company in China, we have already installed over 2200 units of screw feeder weighers all the world . Therefore, we have confidence that our multihead weigher prices are highly competitive, and our product quality is recognized by our customers. We also build our production solutions to meet the budget requirements of our customers

Contact us to let more sticky products use automatic weighing to create more benefits for you.