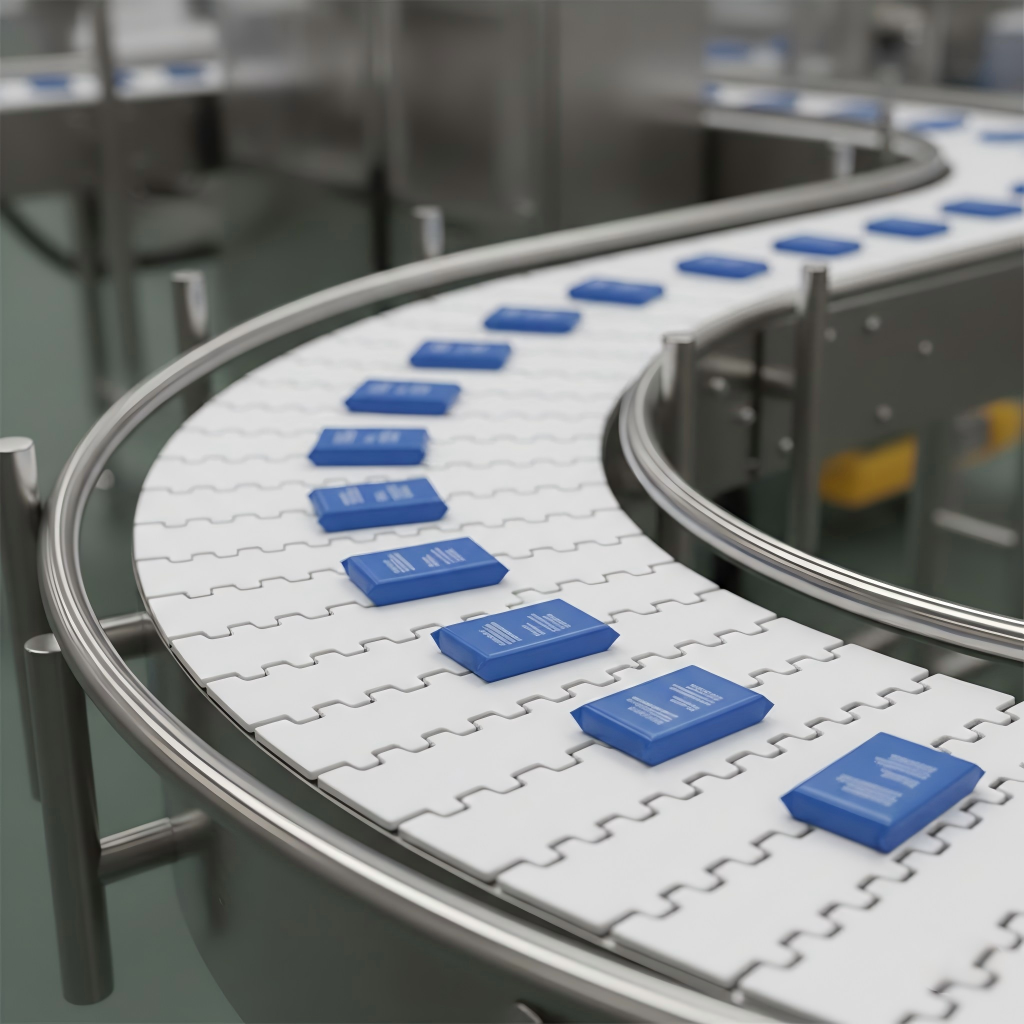

In the world of automated manufacturing and packaging, the “little things” often matter the most. When you are dealing with delicate electronics, pharmaceutical vials, or small food items, a standard conveyor belt simply won’t cut it.

If your production line struggles with product tipping, misalignment, or damage during transfers, the solution lies in a specific engineering marvel: the small-pitch modular conveyor belt.

What is “Small Pitch” and Why Does It Matter?

In conveyor terminology, “pitch” refers to the distance between the center points of two contiguous pins. While standard belts might use larger links, a small-pitch modular belt (typically inches or smaller) is designed for high-precision movements.

The smaller the pitch, the tighter the radius it can navigate around sprockets. This creates a “tight transfer” effect that is crucial for maintaining product orientation.

3 Key Benefits for Precision Product Handling

1. Seamless Transfers (The End of the “Gap”)

Traditional belts often require large rollers, creating a significant gap between two conveyor sections. For small products, these gaps are “dead zones” where items can get stuck or fall. Small-pitch belts allow for nose-bar transfers, minimizing the gap so even the smallest items glide smoothly from one stage to the next.

2. Reduced “Chordal Action”

Large-pitch belts experience a pulsing effect known as chordal action as they wrap around sprockets. This vibration can cause delicate products to bounce or shift. Small-pitch designs significantly reduce this vibration, ensuring a stable, “glass-like” flow of goods.

3. Exceptional Durability and Hygiene

Unlike fabric belts that fray or slip, modular belts are made of high-performance polymers. They are:

Easy to clean: Ideal for food and pharma packaging.

Self-tracking: No more downtime spent adjusting belt tension or alignment.

Versatile Applications: Where Precision Meets Performance

From the cleanroom to the packaging floor, these belts are the backbone of various industries:

Dược phẩm: Handling small vials and blister packs without tipping.

Thực phẩm & Đồ uống: Navigating tight turns in cooling or proofing processes for baked goods.

Thiết bị điện tử: Static-dissipative materials for transporting microchips and sensors.

E-commerce & Packaging: Perfect for compact conveyor solutions where floor space is limited but throughput must remain high.

Choosing the Right Modular Belt for Small Products

Selecting a compact conveyor solution isn’t just about size; it’s about the synergy between the material, the pitch, and the surface texture. Whether you need a “Flush Grid” for airflow or a “Flat Top” for maximum stability, the right modular belt is an investment in your line’s overall efficiency.

Efficiency Tip: If you are currently using traditional fabric belts for small parts, switching to a modular small-pitch system can reduce product loss by up to 30% and cut maintenance costs in half.

Phần kết luận

Precision handling is the difference between a high-yield production line and a logistical headache. By implementing small-pitch modular conveyor belts, you ensure that even your smallest products are treated with the highest level of care and accuracy.

Ready to optimize your production line? Nếu bạn đang tìm kiếm một modular belt for small products or need a custom precision product transfer conveyor design, our team is here to help.

Contact us today for a technical consultation or a quick quote!