Pequeño en tamaño, gigante en impacto

¿Qué tan importante puede ser una soldadura? A simple vista, las soldaduras son diminutas, a menudo ocultas bajo elegantes paneles de acero inoxidable, invisibles para los clientes. Sin embargo, en nuestro taller, cada técnico las trata con sumo cuidado. ¿Por qué?

Porque cada soldadura es una promesa: de resistencia, seguridad y fiabilidad a largo plazo.

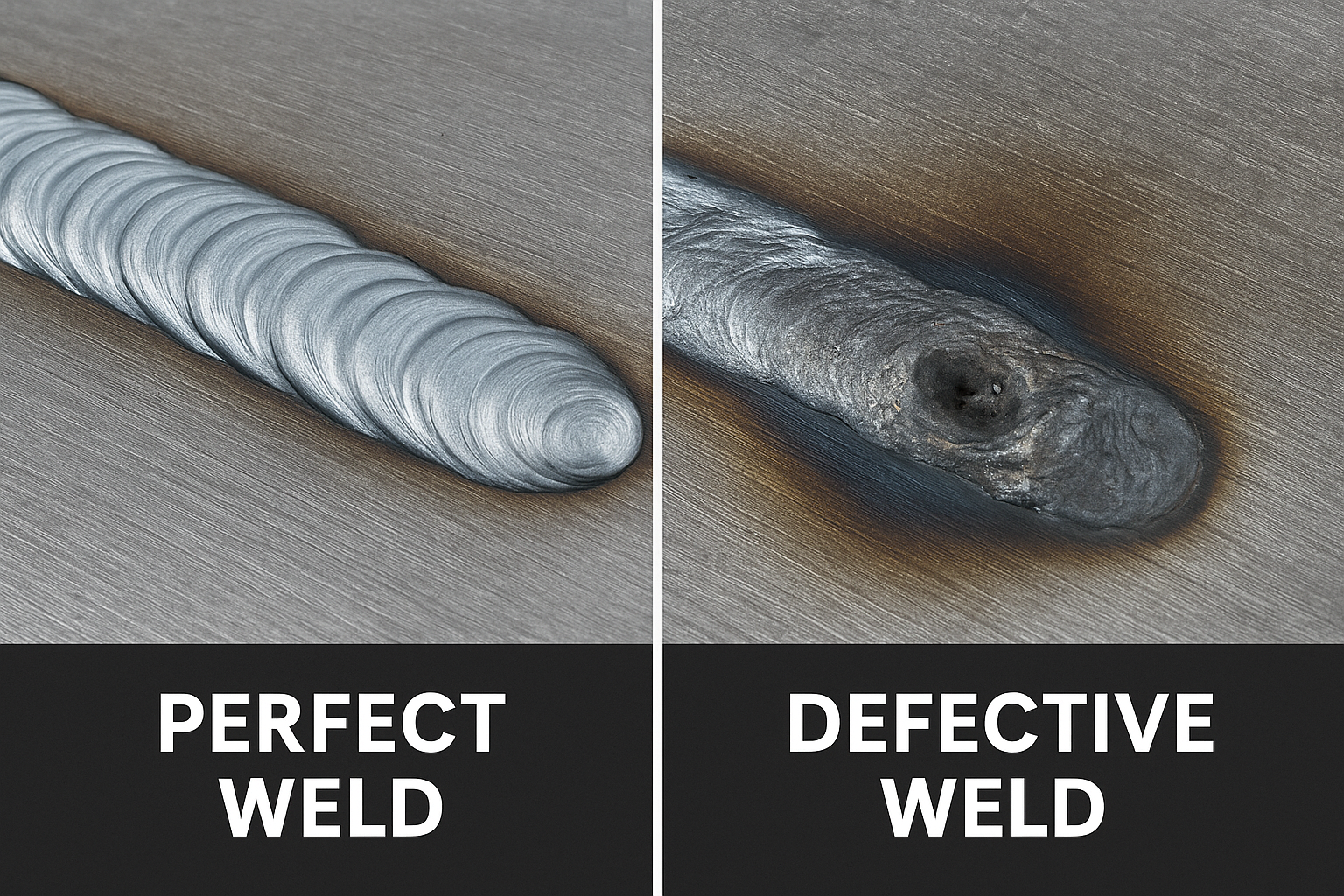

En las máquinas de envasado de alimentos, las soldaduras sirven como enlaces neuronales, uniones estructurales y vías eléctricasUna sola soldadura fría, un punto quemado en exceso o una grieta invisible pueden provocar acumulación de calor, cortocircuito, cambios estructurales o, peor aún, un colapso bajo carga.

Tomemos como ejemplo la plataforma de soporte de una pesadora multicabezal: una soldadura defectuosa puede provocar deformaciones estructurales con el tiempo. Esto no solo afecta la precisión, sino que pone en riesgo la seguridad de la máquina y del trabajador. Un defecto aparentemente invisible se convierte en una bomba de relojería.

La mano de un maestro: Li el soldador

Li es nuestro ensamblador más experimentado. Con más de 15 años de experiencia en el sector, sus movimientos de soldadura son rítmicos y serenos: comienza con los puntos de anclaje, luego une cada terminal con calor constante y termina con un pulido minucioso.

No se apresura. Su regla: «Siempre puedes ir más rápido, pero ¿puedes garantizar que la soldadura dure diez años?».

Incluso si una unión está oculta a la vista, Li insiste en la perfección. ¿Un acabado tosco? Lo rehará. "Si no lo aceptaría yo mismo, ¿cómo puedo enviárselo a un cliente?"

Y cuando entrena a nuevos soldadores, siempre comienza con esta frase:

Mantén la mano firme, pero el corazón en calma. Una soldadura inestable puede acortar la vida útil de una máquina en años.

El ojo agudo del control de calidad

Cada soldadura pasa por tres capas de inspección: autoverificación, verificación por pares y luego nuestro equipo de control de calidad oficial, equipado con lupas, medidores y herramientas de prueba no destructivas.

Sus estándares son estrictos, y con orgullo. La tolerancia es de ±0,1 mm. ¿Una pequeña picadura superficial? Marcada para retrabajo.

Tomemos esta escena de nuestra tienda:

Li termina una soldadura impecable en un soporte. Se siente seguro. El técnico de control de calidad frunce el ceño: demasiado estrecho. Saca la lámina estándar, el calibre de ángulos y luego una solicitud firme de retrabajo. "Esa punta no aguantará la vibración lateral".

Nunca es personal. Ambos comparten la misma misión: crear una máquina que no falle.

Nuestro responsable de control de calidad dice:

Mi firma significa que esta estación pasó. Firmo por la seguridad del cliente, no por la velocidad.

Construido sobre sistemas, respaldado por la cultura

Nuestra soldadura de alta calidad no es solo artesanía, es una sistema:

- Normas de procedimiento de soldadura (WPS) Guía cada material, corriente y ángulo

- Solo soldadores certificados:Todos los operadores pasan evaluaciones internas antes de tocar construcciones reales.

- Registros de calidad trazables Vincular el historial de soldadura de cada máquina a técnicos específicos

- Mejora continua:Registramos y analizamos todos los defectos detectados para evitar que vuelvan a ocurrir.

En nuestro taller, las pancartas dicen:

“Suelda como si fuera tu nombre el que está en juego”.

Incluso organizamos competiciones periódicas en las que otorgamos el título de “Estrella de la soldadura” por la excelencia constante.

Por qué la calidad de la soldadura es importante para usted

¿Qué significa una buena soldadura para nuestros usuarios?

Significa una línea de envasado ininterrumpida. Una selladora de bolsas que aguanta. Un soporte de cinta transportadora que no se rompe tras dos años de uso intensivo. No se trata solo de rendimiento, sino de tranquilidad.

Una sola soldadura une más que metal: nos conecta con su confianza.

Nuestro compromiso

En Fill Package, tratamos cada soldadura como si fuera una firma. Representa nuestra promesa de durabilidad, seguridad y calidad duradera.

Creemos Cada pequeña soldadura refleja un gran compromiso.

Entonces, la próxima vez que presione el botón de Inicio y su máquina comience a funcionar, recuerde que no solo funciona con electricidad, sino con la concentración de cada soldador, la diligencia de cada inspector y nuestra definición compartida de la palabra: "confiable".