— Una guía práctica sobre la relación coste-rendimiento en equipos de envasado automático

Cuando se trata de máquina envasadora automática En lo que respecta a la selección, muchos compradores se encuentran en una encrucijada entre el prestigio y la practicidad.

¿Debería optar por la ingeniería probada en el tiempo de Alemania, Japón o los EE. UU.?

¿O debería considerar una solución de rápida evolución y rentable? Fabricante chino de máquinas de embalaje?

Seamos honestos: en términos de materiales base, mecanizado de precisión, lógica de control y legado industrial, las máquinas de envasado de países desarrollados aún representan la cumbre mundial. Marcas como Ishida pueden alcanzar... Más de 180 paquetes por minuto, con tolerancias de piezas de hasta ±0,01 mm, hermosa estética y vida útil prolongada de más de 10 años.

Pero cuando estás tratando con productos no estándar, un presupuesto limitado o simplemente necesita algo que comience a funcionar rápidamente, la automatización china está reescribiendo la ecuación del valor.

¿Qué hacen mejor las máquinas de embalaje chinas?

No, no son perfectos. Pero lo son. Lo suficientemente bueno para resolver problemas de embalaje del mundo real, de manera asequible, rápida y flexible..

✅ 1. Diseño que prioriza la función

Olvídese de las comodidades: los equipos de envasado chinos están diseñados para funcionar de manera eficiente, reducir el tiempo de inactividad y manejar desafíos específicos del producto, como salsas, artículos irregulares o SKU de múltiples tamaños.

✅ 2. Ventaja de costo: 40–60% menos

Un estándar pesadora multicabezal Desde Llenar paquete comienza en $4,500, en comparación con $80,000 o más para una marca global, eso es menos de la mitad del costo con 85% de la funcionalidad.

✅ 3. Plazos de entrega rápidos, personalización rápida

-

Máquinas estándar: 10–30 días

-

Máquinas personalizadas: hasta 60–65 días

Las máquinas occidentales a menudo requieren 14–18 semanas o más largo.

✅ 4. Servicio posventa rápido, especialmente en Asia

Con agentes de Fill Package en todo el sudeste asiático, podemos ofrecer:

-

Diagnóstico remoto en 24 horas

-

Soporte en sitio en menos de 72 horas

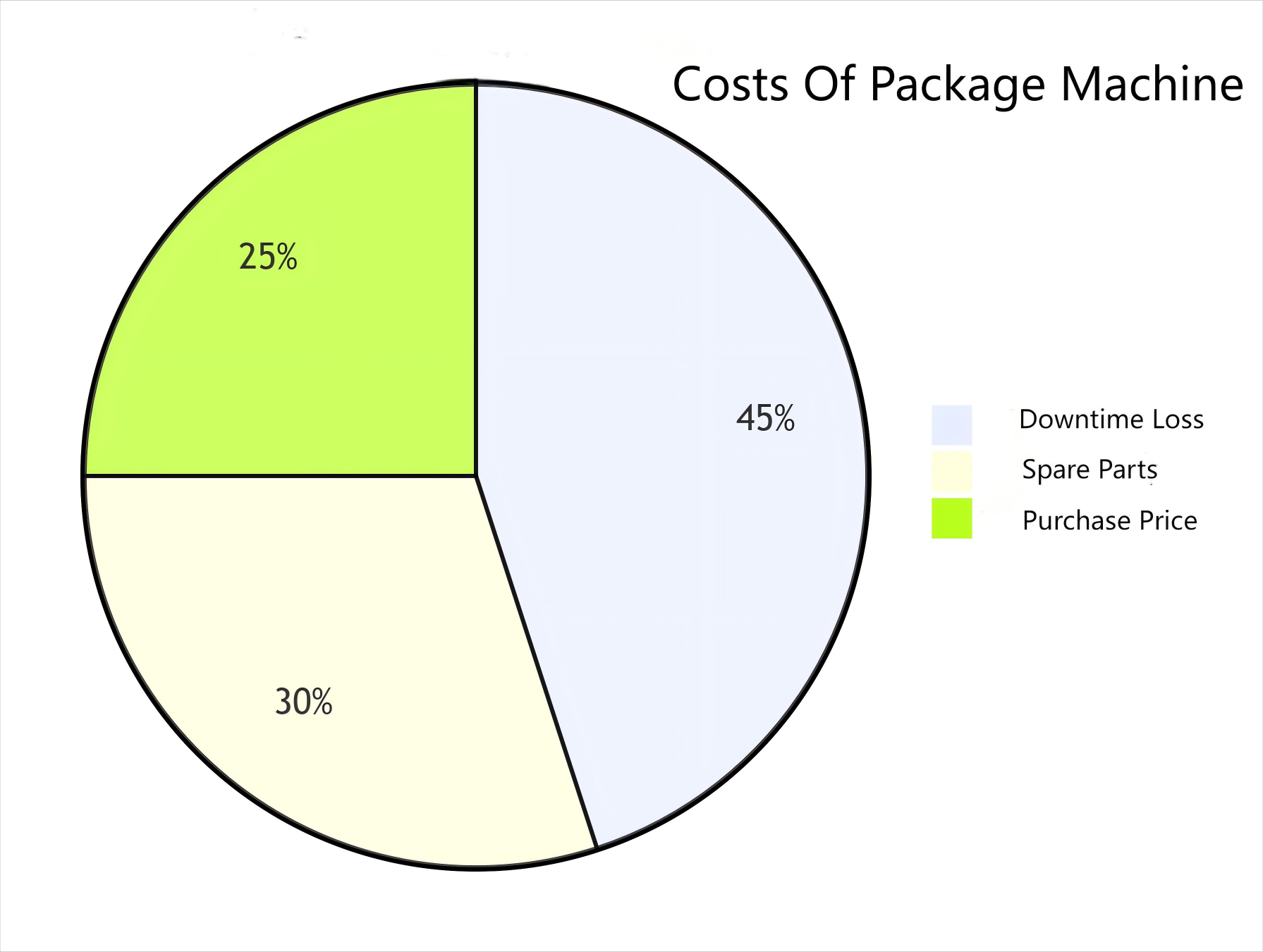

Análisis de la realidad del ROI: Comparación de costos a 3 años

Tomemos un ejemplo real: comparar un 10 cabezas pesadora automática multicabezal:

| Categoría | Gran marca | Llenar el paquete |

|---|---|---|

| Precio de compra | $80,000 | $4,500 |

| Repuestos (3 años) | $12,000 | $1,000 (1er año gratis) |

| Pérdida por tiempo de inactividad* | $9,000/año × 3 = $27,000 | $3.000/año × 3 = $9.000 |

| Costo total de 3 años | $119,000 | $14,500 |

*Estimado en $3,000/día x 3 días/año por tiempo de inactividad de producción.

Pregúntese: ¿Gastaría 1/10 del costo del 85% en relación calidad-precio? Soporte de “nivel de seguro” 24/7?

Construimos con componentes premium de origen global

Aunque tengamos nuestra sede en China, seguimos estándares de calidad globales. Aquí tienes un vistazo a... componentes principales de nuestro equipos de envasado de alimentos:

Sistema de control

-

Pantalla táctil: WEINVIEW / Taiwán

-

PLC: Mitsubishi / Japón

-

Servomotor: Schneider / Francia

-

Controlador de temperatura: AESET / China

-

Sensor fotoeléctrico: CNBDL / China

Neumática

-

Todos los cilindros y válvulas: AirTAC / Taiwán

Electricidad

-

Relés: OMRON / Japón

-

Estado sólido: JIALE / Suiza

Seguridad y movimiento

-

Sensor de proximidad: FOTEK / Taiwán

-

Disyuntor: CHNT / China

-

Cinturón: YONGLI o Hongsbelt

-

Motores: SEW

Palabra final: No es el más caro, pero sí el más adecuado

Hay un dicho:

Una marca global es como la pareja ideal, pero no todos se casan con su sueño. La compatibilidad perfecta es más importante.

En la automatización del embalaje, la la mejor inversión es el que equilibra costo, rendimiento y flexibilidad para su etapa actual, no solo la marca en la placa de identificación.

Cuéntenos cuál es su producto y su problema: le mostraremos la solución ideal

Sólo dinos:

✅ ¿Qué estás empaquetando? (por ejemplo, papas fritas, rodajas de mango, pasta de camarones)

✅ Tu experiencia de inactividad más dolorosa

✅ Rango de presupuesto

Te enviaremos:

🎁 Un informe de recomendación de equipos personalizado

🎥 Un video del mundo real que resuelve tu problema exacto