Precisión de 0,01 g: Máquinas de envasado de cannabis inteligentes para la industria del cannabis

Cuando cada gramo vale más, la precisión lo es todo. Nuestras máquinas de envasado de cannabis de alta precisión garantizan la mejor presentación de sus productos, maximizando sus márgenes de beneficio y cumpliendo con los estrictos requisitos de cumplimiento.

Dile adiós al desperdicio y adopta la precisión rentable

En la industria del cannabis, la precisión no es solo una métrica técnica; está directamente relacionada con el resultado final. Los métodos tradicionales de pesaje y envasado suelen enfrentarse a graves desafíos:

-

El pesaje manual es lento, ineficiente y propenso a errores.

-

El llenado excesivo consume silenciosamente las ganancias todos los días.

-

El manejo brusco daña los frágiles tricomas, lo que reduce la calidad del producto y el valor minorista.

-

Las regulaciones cada vez más estrictas exigen dosis exactas de 3,5 g, 5 g o 10 g.

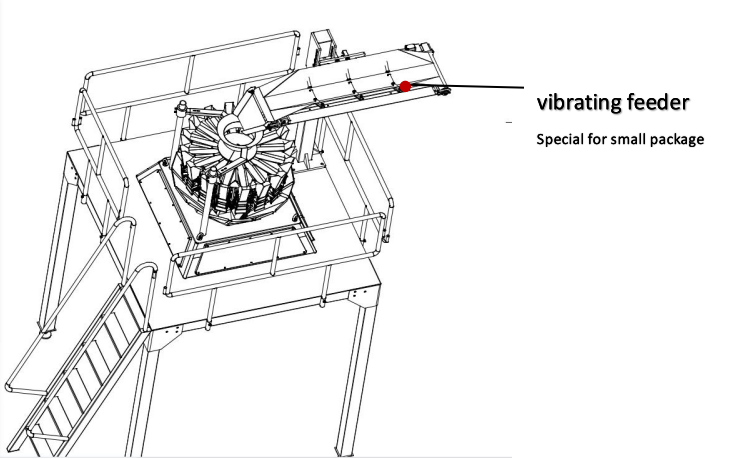

Nuestro Mini sistema de pesaje de cannabis multicabezal fue diseñado para resolver estos problemas. Con revolucionarios Tecnología de pesaje de alta precisión de ±0,03 g, minimiza el desperdicio y ahorra decenas de miles en costos de materia prima cada año. Combinado con nuestro sistema de alimentación por vibración ultraligero y lógica de pesaje madre-hijoCada flor se manipula con cuidado, logrando una distribución de peso impecable. Ya sea envasando frascos de 3,5 g listos para la venta o bolsas premium de 5 g, nuestras máquinas le permiten cumplir con las normativas y ser competitivo.

Por qué el cannabis requiere una máquina de envasado diferente

Los productos de cannabis tienen propiedades físicas únicas que hacen que los equipos de pesaje tradicionales no sean adecuados:

- Baja densidad aparente, alto valor minorista

- Tricomas frágiles Se daña fácilmente por vibración o caídas desde cierta altura.

- Formas irregulares de los cogollos y fragmentos de tamaño mixto

- Residuos pegajosos y polen que obstruyen los alimentadores estándar

- Normas estrictas de cumplimiento requiriendo pesos exactos

Por eso no construimos máquinas “estándar”. Diseñamos máquinas especializadas de envasado de cannabis que satisfacen las necesidades reales de los productores, procesadores y distribuidores.

Nuestras ventajas tecnológicas

Sistema revolucionario de alimentación personalizado

- Evita el sobrellenado causado por la vibración.

- La alimentación con poca fuerza garantiza un movimiento suave y una rotura mínima del producto.

- Optimizado para material de cannabis ligero con Alimentación incremental de 0,1 g y altura de caída mínima.

Pesaje de alta precisión inigualable

- Sensores con Sensibilidad de 0,01 g.

- Logra Precisión de ±0,03 g en el rango de 3 a 10 g.

- La precisión líder en la industria garantiza un cumplimiento constante.

Lógica inteligente para pesar madre e hijo

- Los cogollos grandes tienen prioridad.

- Se añaden segundos pequeños fragmentos para alcanzar el peso objetivo exacto.

- Inspirado en la lógica de pesaje de Ishida, personalizado para los flujos de trabajo de cannabis.

Diseño resistente al polvo y antiadherente

- Tolva de bajos residuos con ángulo poco profundo para reducir la acumulación.

- Cubiertas protectoras para controlar partículas finas.

- Las superficies antiestáticas garantizan un funcionamiento limpio.

-

Rendimiento estable a largo plazo con fácil limpieza.

Especificaciones técnicas clave

| Parámetro | Especificación | Ventaja |

|---|---|---|

| Precisión de pesaje | Hasta ±0,03 g | La precisión líder en la industria reduce la pérdida de materia prima |

| Rango de peso objetivo | 0,5 g – 10 g | Perfecto para paquetes minoristas de cannabis. |

| Sistema de alimentación | Vibración ultraligera / micropasos | Manipulación cuidadosa de brotes y fragmentos |

| Número de cabezales de pesaje | 10–14 minicabezales de pesaje (0,2 L) | Diseño compacto, alta eficiencia. |

| Funciones lógicas | Madre-hijo, autoajuste, memoria | Operaciones inteligentes para diferentes cepas |

| Acabado de la superficie | Teflón, acero inoxidable pulido, antiestático. | Antiadherente, fácil limpieza, estándar GMP |

| Integración | Compatible con frascos, bolsas, bandejas y pre-rolls. | Configuraciones de línea flexibles |

Amplia gama de aplicaciones

Nuestro pesadoras multicabezal para cannabis Están diseñados para el cannabis pero también funcionan con otros productos de alto valor y pequeño volumen:

-

Flor de cannabis (cogollos y batidos): paquetes intactos y precisos

-

Gomitas de cannabis – dosificación precisa, conformidad con la normativa alimentaria

-

Hojas de té de primera calidad – Estructura de la hoja conservada, mezclas exactas

-

Semillas (cáñamo, chía, girasol, etc.) – relleno suave y preciso

-

Hierbas y botánicos – medición precisa sin pérdida de potencia

-

Otros productos de alto valor necesitando precisión de subgramos

¿Por qué elegir nuestras máquinas de envasado de cannabis?

ROI tangible

-

Reducir el desperdicio de productosAhorre miles anualmente en materia prima.

-

Cumplimiento garantizado:Eliminar riesgos de sobrepeso/bajo peso.

-

Imagen de marca más fuerte:Ofrecer una calidad de producto constante.

-

Márgenes de beneficio más altos:Cada gramo se mide y se maximiza.

Soporte técnico completo

-

Prueba de producto gratuita para tus cepas.

-

Configuraciones personalizadas para sus formatos de producto.

-

Capacitación en sitio para sus operadores.

-

Soporte 24/7 con compromiso de servicio de por vida.

Mejores prácticas para el pesaje y envasado de cannabis

Controles ambientales

-

Temperatura y humedad: 18–22 °C, 45–551 TP3T humedad relativa.

-

Configuración antiestática:Evita que los brotes y el polen se adhieran.

-

Control del flujo de aire:Elimina corrientes de aire que afecten la precisión en microgramos.

Manipulación de productos

-

Estabilidad de la humedad:El contenido de agua equilibrado garantiza un peso constante.

-

Diferencias de densidad de tensión:Ajuste la configuración de vibración para Sativa vs Indica.

-

Gestión del polvo y el polen:El sistema de recolección evita la contaminación.

Protocolos operativos

-

Estabilización del precalentamiento:30 minutos antes de la operación.

-

Calibración de rutina:Comprobación rápida diaria, calibración completa semanal.

-

Saneamiento:Limpie profundamente antes de cambiar de cepa para evitar la contaminación cruzada.

Guía de selección de equipos de envasado de cannabis

-

Escala de producción:Máquinas de 10 cabezales (200–400 paquetes/hora) vs. máquinas de 14 cabezales (500–800 paquetes/hora).

-

Nivel de precisión:±0,05 g para granel, ±0,03 g para venta minorista comercial, ±0,01 g para productos premium.

-

Cumplimiento:Asegurarse de que las máquinas cumplan Certificaciones NTEP/OIML donde sea necesario.

-

Integración:Compatible con Máquinas para embolsar cannabis, llenadoras de frascos, líneas de envasado de pre-rollos.

-

ROI:Ahorre entre 2 y 51 TP3T en costos de materia prima, reduzca los costos laborales hasta en 801 TP3T y mejore la competitividad del mercado.

Comience hoy su viaje hacia el embalaje de precisión

No permita que un embalaje impreciso afecte sus ganancias. Contacte con Fill-Package hoy mismo para obtener un paquete a su medida. solución de envasado de cannabis.

✔ Pruebas y optimización de productos gratuitas

✔ Asesoramiento experto en el lugar

✔ Garantía de 1 año, soporte de por vida

✔ Pago y financiación flexibles

📩 Correo electrónico: info@fill-package.com

📞 Teléfono: +86-13536680274