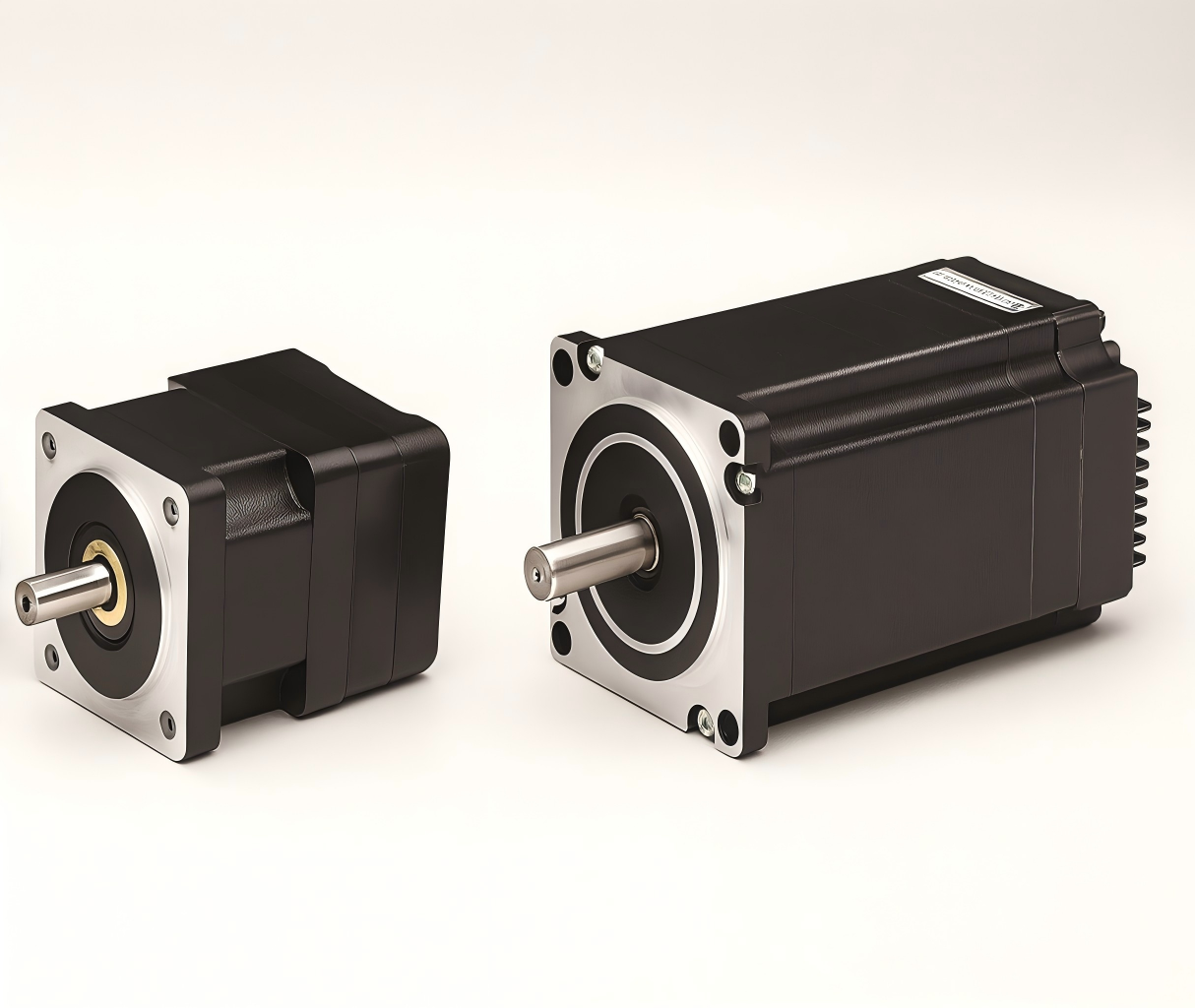

Introduction to Stepper Motors

A stepper motor is a brushless, synchronous electric motor designed to divide a full rotation into a large number of equal steps. Its construction typically includes:Stator: Equipped with multiple electromagnetic coils arranged in phases.Rotor: Either a permanent magnet or a variable reluctance design with finely toothed poles.Drive Circuit (Controller): Sends timed pulses to the stator coils, creating a rotating magnetic field.

Each incoming pulse rotates the shaft by a fixed step angle (commonly 1.8° or 0.9°). By controlling the number and frequency of these pulses, stepper motors achieve precise position and speed control without needing feedback sensors in open-loop systems.

Key Advantages:Exactitud: Ideal for applications requiring repeatable movement;Simple Control: Position and speed directly proportional to input pulses;Reliability: No brushes = less wear and maintenance.

Typical Applications: 3D Printers, CNC Machines, Robotics, Food Packaging machines & Labeling Machinery .Etc

In short, stepper motors are the backbone of modern automation, offering a cost-effective balance between precision, durability, and control simplicity.

What is a Stepper Motor Used For?

A stepper motor is a brushless DC motor that converts digital pulse signals into precise mechanical angular displacement. Each input pulse makes the shaft rotate by a fixed angle—called a “step.” This step-by-step motion allows excellent positioning accuracy, speed control, and repeatability.

Aplicaciones comunes:

- Package Machine: Food package machines, Pesadora multicabezal, Transportadores …

- 3D Printers: Precisely control print head and bed movement.

- CNC Machines: Drive tools for accurate cutting and carving.

- Robotics: Achieve precise joint rotation.

- Medical Machines: Ensure accurate sample positioning in analyzers and scanners.

Stepper Motor Working Principle

The principle of a stepper motor is based on electromagnetism and step-by-step control.Each time an input pulse signal is received, the motor rotates by a fixed angle (known as the “step angle”).

- Electromagnetic Excitation: The controller energizes one set of stator coils, creating a magnetic field.

- Rotor Alignment: The rotor (a toothed permanent magnet) aligns itself with the energized stator teeth.

- Sequential Switching: The controller de-energizes the current coil and then energizes the next one, shifting the stator field.

- Stepping Motion: The rotor moves in steps, following the rotating magnetic field.

- Pulse Frequency = Speed

- Pulse Count = Position

This makes stepper motor speed control and position control straightforward, highly repeatable, and precise.

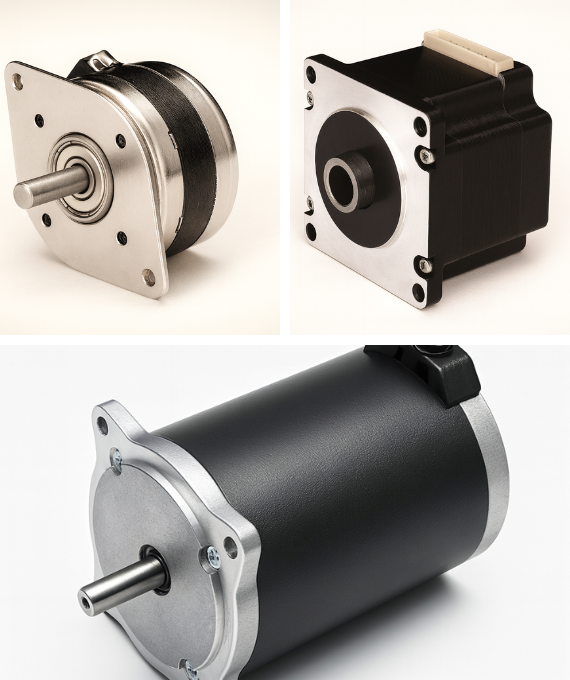

Stepper Motor Types

1. Standard Two-Phase / Three-Phase / Five-Phase Stepper Motors

- Description: The foundation of our product line. More phases = smoother performance.

- Best For: Automatic food machines , CNC machines, textile, and packaging equipment.

2. Closed-Loop Stepper Motor with Controller

- Description: Equipped with a high-precision encoder for real-time feedback. Eliminates step loss while keeping cost advantages of steppers.

- Best For: Applications requiring absolute reliability and zero tolerance for missed steps.

3. Integrated Stepper Motors (Motor + Controller)

- Description: Combines the stepper motor and driver in one compact unit. Simplifies wiring, reduces electromagnetic interference, and saves space.

- Best For: Distributed control systems and compact equipment designs.

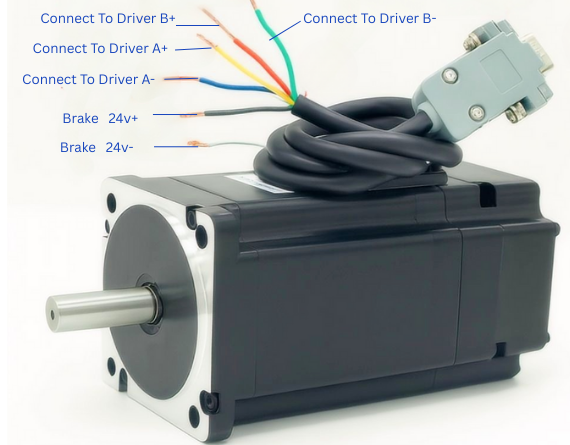

4. Special Application Stepper Motors (Hollow Shaft / With Brake)

- Hollow Shaft: Allows cable routing through the motor, simplifying layouts.

- With Brake: Ensures safety in vertical motion or power-off conditions.

- Best For: Robotics, elevators, and unique automation challenges.

Stepper Motor vs Servo Motor

One of the most common questions in motion control is: What is the difference between a servo motor and a stepper motor?

| Característica | Motor paso a paso | Servo Motor |

|---|---|---|

| Control Method | Open-loop by default; can also be closed-loop with an encoder | Always closed-loop with encoder feedback |

| Cost | Lower cost, simple system | Higher cost, complex system |

| Low-Speed Performance | High torque at low speed may show vibration | Very smooth and stable at low speed |

| Rendimiento de alta velocidad | Torque drops at higher speeds | Maintains rated torque even at high speed |

| Overload Capability | No overload tolerance—may skip steps | Strong overload capacity (up to 3× rated torque) |

| Respuesta | Quick start/stop | Faster dynamic response |

| Best Use | Precise positioning, constant speed, cost-sensitive | High dynamic motion, heavy load, torque-intensive tasks |

Conclusion:

-

Choose a stepper motor para precise positioning and cost efficiency.

-

Choose a servo motor para high-speed, high-torque, or overload-prone environments.

Core Technical Specifications

| Parámetro | Descripción | Why It Matters |

|---|---|---|

| Frame Size | Motor flange dimensions | Determines installation compatibility; larger sizes = more torque |

| Holding Torque | Static holding force | Ensures load stability |

| Step Angle | Angular movement per step | Smaller angle = higher precision |

| Phase Current | Driver matching current | Impacts torque and heating |

| Body Length | Motor body size | Longer body = more torque in same frame size |

| Phases | 2, 3, or 5 | More phases = smoother operation |

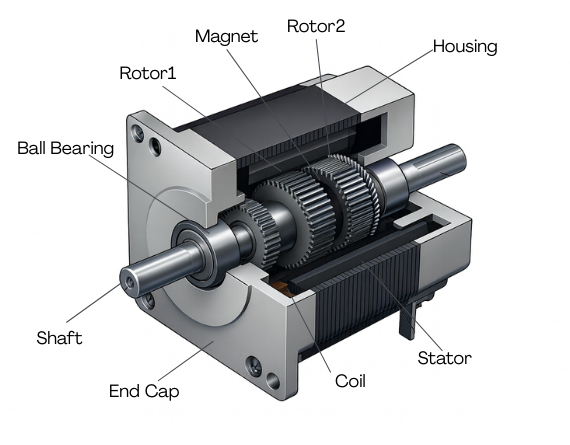

Internal Structure of Stepper Motors

El precise motion of stepper motors comes from their robust mechanical and electromagnetic structure. Every high-quality stepper motor is built with meticulous craftsmanship, designed to convert digital pulses into reliable physical motion.A typical hybrid stepper motor is composed of three major assemblies working in harmony:

Rotor (Rotating Core):

- Permanent Magnet: Provides the base magnetic field, essential for torque generation.

- Rotor Core: Laminated silicon steel sheets with finely machined micro-teeth. These teeth interact with the stator field to create stepping motion.

- Shaft: Transmits rotary motion to the external load.

- Ball Bearings: Mounted at both shaft ends, supporting smooth, low-friction rotation even at high speed.

Stator (Stationary Part):

- Stator Core: Built from laminated silicon steel, with multiple large poles around its inner wall.

- Windings (Coils): High-purity copper wires wound around each pole. By energizing these windings in sequence, a rotating magnetic field is created to drive the rotor step by step.

End Caps (Housing):

- Front & Rear End Caps: Usually made of high-strength aluminum alloy or steel, they precisely enclose the rotor and stator while holding bearings in place.

- Front End Cap (Mounting Flange): Determines the motor’s standardized frame size.

- Stepper Motor Specifications

- Stepper Motor Speed Control

- Stepper Motor Wiring

| Electrical Specifications | Mechanical Specifications | ||

|---|---|---|---|

| Step Angle Accuracy | ±5% | Dielectric Strength | AC 500V, 1 minute |

| Ambient Temperature | -20℃ ~ +50℃ (non-freezing) | Insulation Resistance | 100 MΩ Min. at 500V DC |

| Other Specifications | Radial Play | 0.02 mm Max. (500g load) | |

| Max. Allowable Temperature | 80℃ | Axial Play | 0.08 mm Max. (500g load) |

| Insulation Class | Class B |

Explanation of Terms:

- Step Angle Accuracy: The tolerance on the motor’s step angle (e.g., 1.8° ±5%).

- Max. Allowable Temperature: The maximum safe temperature of the motor body during operation.

- Ambient Temperature: The acceptable range of the temperature of the surrounding air where the motor operates.

- Insulation Class: A classification (Class B is common) defining the thermal tolerance of the motor’s insulation system.

- Dielectric Strength (Hi-Pot Test): The ability of the insulation to withstand a high voltage potential between the windings and the motor frame without breaking down.

- Insulation Resistance: A measure of the resistance of the insulation between the windings and the motor frame.

- Radial Play: The maximum permissible movement (backlash) of the shaft when a force is applied perpendicular to the shaft axis.

- Axial Play: The maximum permissible movement (backlash) of the shaft when a force is applied along the shaft axis.

Stepper motors rotate at a speed proportional to the frequency of input pulses. For smooth acceleration and deceleration, you need a controller capable of precise pulse-frequency adjustment.

Our drivers support microstepping up to 256 subdivisions, allowing ultra-smooth motion even at very low speeds.

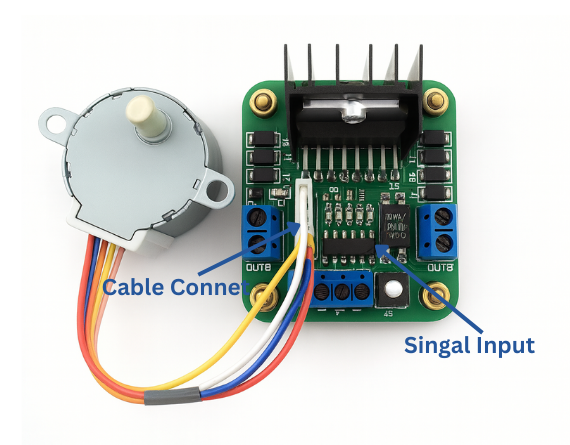

Correct wiring is essential for performance.

-

Bipolar Wiring (4 wires): Delivers higher torque, requires more complex drivers.

-

Unipolar Wiring (5 or 6 wires): Simpler to drive, slightly less torque-efficient.

We provide clear wiring diagrams and technical support to ensure seamless integration.

Producto relacionado

Ready to Power Your Next Project?

Our engineering team is ready to support your project from motor selection to full integration.

📞 Technical Hotline: +0086-13536680274

📧 Email:info@fill-package.com

💬 Online Form: https://fill-package.com/contact-us/

Let’s bring precise and powerful motion to your system.

.

Stepper motors are DC-powered devices. They cannot be driven directly from a raw DC power supply but require a stepper motor controller/driver, which translates input pulses into precise coil energizing sequences.

Most systems operate from a regulated DC supply, typically 24V to 48V, though industrial models may support wider ranges.

This is the most common selection question.

-

Control Method: Stepper motors usually operate in open-loop control (no feedback), making the system simpler and lower-cost. Servo motors must be closed-loop with encoder feedback, making them more complex and expensive.

-

Performance: Stepper motors provide high torque at low speeds, but torque drops at higher speeds, and they cannot handle overload. Servo motors maintain stable torque across the entire speed range and have strong overload capability.

-

Solicitud: Choose a stepper motor if your application requires cost-effective, precise positioning with stable loads. Choose a servo motor if your project requires very high dynamic response, speed, or torque control.

-

Nuestra solución: Nuestro closed-loop stepper motor series combines the benefits of both—servo-like reliability at a much lower cost.

Holding torque is the maximum torque a motor can provide while energized but not rotating. It is a key performance indicator of how much “force” the motor can hold.

- A higher holding torque is better, but only within reason.

- Overspecifying torque will increase cost, size, and power consumption unnecessarily.

- The best practice is to calculate the maximum torque needed for your application and select a motor with a 30–50% safety margin.

- Open-Loop: The controller only sends pulse commands without checking if the motor actually reached the position. Simple and cost-effective, suitable for most basic applications.

- Closed-Loop: The motor has an encoder that provides real-time feedback. The driver compares the command position with the actual position, correcting any errors immediately. This dramatically improves accuracy and reliability, especially under heavy loads

- Two-Phase: The most common and cost-effective, suitable for general automation.

- Three-Phase: Provides smoother motion and lower vibration compared to two-phase.

- Five-Phase: Delivers the smoothest and quietest operation, with reduced resonance, ideal for high-precision applications.

- Velocidad: Determined by the pulse frequency (pulses per second). Higher frequency = faster speed.

- Direction: Controlled by a direction signal line (DIR pin, high/low level).

- Angle: Determined by the total number of pulses. More pulses = larger rotation angle.

Microstepping is a drive technique that subdivides a motor’s full step (e.g., 1.8°) into many smaller steps.

-

Higher Resolution: Enables much finer positioning.

-

Smoother Motion: Reduces low-speed vibration and noise.

Our drivers support up to 256 microsteps per step for ultra-smooth performance.

Yes—a driver is mandatory. A stepper motor cannot run by connecting directly to a DC supply. The driver converts control signals (pulses and direction) into the correct timing and current for the motor coils.

Yes, heating is normal. Stepper motors continue to draw current even when stationary to maintain holding torque.

-

Safe operation is possible up to 80°C surface temperature.

-

Excessive heat may indicate overcurrent settings on the driver.

-

Nuestro closed-loop and integrated stepper motors include smart current control, reducing unnecessary heating and improving efficiency.

Step loss happens when the motor cannot follow input commands. Common reasons include:

- Load torque exceeding motor capacity.

- Acceleration/deceleration rates set too aggressively.

- Driver current too low.

- Mechanical jamming in the transmission system.

- Supply voltage too low, especially at high speed.

One of the main advantages of stepper motors is bajo mantenimiento:

- No brushes → minimal wear.

- Just ensure clean surfaces and good ventilation.

- Regularly check wiring and connectors.

- Monitor bearings for unusual noise after long-term use.

- Avoid corrosive or extreme environments.