Giới thiệu

Trong sản xuất hiện đại, hệ thống xử lý vật liệu hiệu quả và linh hoạt là chìa khóa cho hoạt động nhà máy liền mạch. Khi quy trình sản xuất trở nên phức tạp hơn và việc sử dụng không gian trở nên quan trọng hơn, các giải pháp vận chuyển truyền thống thường không đáp ứng được yêu cầu bố trí đa dạng của các nhà máy hiện đại.

Điều này đặc biệt đúng đối với ngành chế biến thực phẩm, trong đó khả năng thích ứng của băng tải không chỉ ảnh hưởng đến năng suất mà còn cả chất lượng sản phẩm và an toàn thực phẩm.

Trong bài viết này, chúng tôi khám phá cách hệ thống băng tải—thông qua băng tải thẳng, băng tải nghiêng và băng tải cong —có thể được điều chỉnh để phù hợp với môi trường nhà máy phức tạp. Chúng tôi cũng sẽ nêu bật những cân nhắc cụ thể cho băng tải cấp thực phẩm. Cho dù bạn đang thiết kế dây chuyền sản xuất mới hay nâng cấp dây chuyền hiện có, hướng dẫn này có thể giúp bạn chọn hệ thống băng tải có bố cục phù hợp cho cơ sở của mình.

🟩 Băng tải thẳng: Nền tảng của sản xuất công nghiệp

Băng tải thẳng là những hệ thống cơ bản nhất và được sử dụng rộng rãi nhất trong các dây chuyền sản xuất. cấu trúc đơn giản, hoạt động ổn định, Và bảo trì dễ dàng làm cho chúng trở nên lý tưởng cho chuyển vật liệu theo chiều ngang.

✅ Các tính năng chính:

-

Cấu trúc đơn giản, hoạt động ổn định

Thông thường bao gồm khung, dây đai, động cơ truyền động và hệ thống căng, băng tải thẳng có cấu tạo cơ học đơn giản và đáng tin cậy, có thể sử dụng liên tục trong thời gian dài. -

Thông lượng cao, ứng dụng rộng rãi

Có khả năng vận chuyển khối lượng lớn trên khoảng cách xa, chúng lý tưởng cho bột, hạt, hàng đóng hộp và các sản phẩm thực phẩm đóng gói. Trong ngành thực phẩm, chúng thường được sử dụng cho vận chuyển nguyên liệu thô, chuyển giao giữa các quy trình, Và phong trào hậu đóng gói. -

Vệ sinh và dễ vệ sinh

Băng tải thẳng cấp thực phẩm sử dụng vật liệu không độc hại, chống ăn mòn, chẳng hạn như khung thép không gỉ Và Dây đai cấp thực phẩm PU hoặc PVC, đáp ứng các tiêu chuẩn vệ sinh và giảm thiểu nguy cơ lây nhiễm chéo. -

Sẵn sàng tích hợp hệ thống

Băng tải thẳng đóng vai trò như cấu trúc cơ sở cho các hệ thống hoàn chỉnh. Chúng có thể được tích hợp với băng tải nghiêng và cong để xây dựng một mạng lưới vận chuyển mô-đun có khả năng thích ứng cao.

🔺 Băng tải nghiêng: Phá vỡ ranh giới theo chiều dọc

Trong các nhà máy nhiều tầng hoặc khu vực cần vận chuyển theo chiều thẳng đứng, băng tải nghiêng đóng một vai trò không thể thay thế. Chúng cung cấp một giải pháp nhỏ gọn và hiệu quả cho nâng vật liệu giữa các tầng, tối đa hóa việc sử dụng không gian theo chiều dọc.

✅ Ưu điểm cốt lõi:

-

Khả năng nghiêng dốc

Với các vành đai chuyên dụng—chẳng hạn như thành bên lượn sóng, thanh giằng hoặc các cạnh có viền—băng tải nghiêng có thể đạt tới độ dốc 30° đến 90°, ngăn ngừa sản phẩm bị trượt và đổ.

👉 Ví dụ: Nâng rau đã rửa lên trạm cắt hoặc chuyển hàng hóa đóng gói lên kho trên cao. -

Tiết kiệm không gian và chi phí

So với thang máy hoặc thang nâng thẳng đứng, băng tải nghiêng có cơ chế đơn giản hơn, bảo trì ít hơn, Và dấu chân nhỏ hơn, giảm đầu tư vốn và cơ sở hạ tầng. -

Tương thích với thực phẩm và có thể rửa sạch

Được xây dựng với khung thép không gỉ và dây đai an toàn thực phẩm, băng tải nghiêng trong ngành công nghiệp thực phẩm dễ vệ sinh và bền bỉ trong môi trường rửa sạch.

👉 Ví dụ: Trong các nhà máy làm bánh, họ chuyển bột từ máy trộn sang máy chia trong khi vẫn đảm bảo vệ sinh. -

Ứng dụng đa ngành

Cũng được sử dụng trong hậu cần thương mại điện tử, kho lạnh, trung tâm dược phẩm và trung tâm bưu kiện, băng tải nghiêng xử lý việc chuyển tải qua sàn, đường dốc, cầu và địa hình dốc.

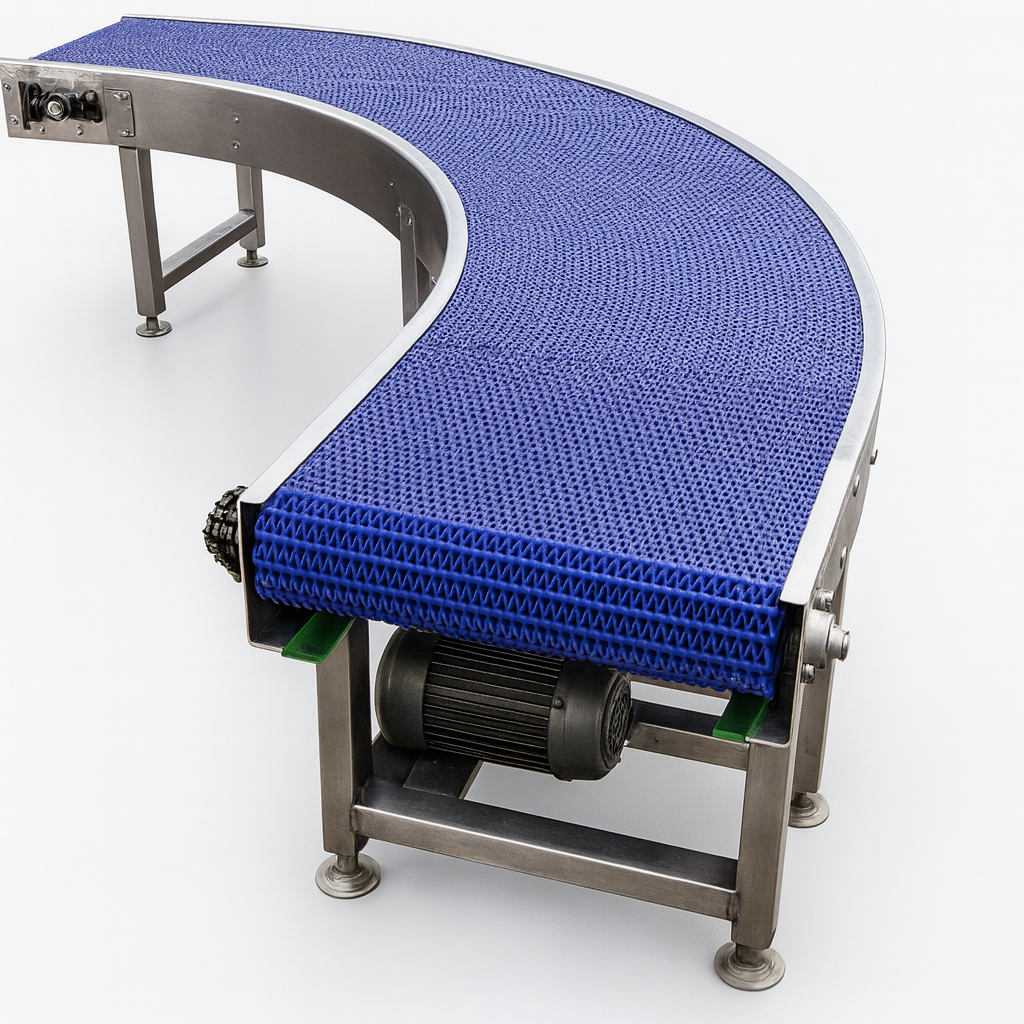

🔄 Băng tải cong: Tính linh hoạt cho các đường dẫn phức tạp

Trong nhiều cách bố trí nhà máy, vận chuyển theo đường thẳng không phải lúc nào cũng khả thi. Đó là nơi băng tải cong đi vào—cho phép dòng vật liệu thay đổi hướng, di chuyển xung quanh chướng ngại vật hoặc liên kết các giai đoạn sản xuất khác nhau một cách liền mạch.

✅ Lợi ích chính:

-

Nhiều góc quay

Băng tải cong có thể được tùy chỉnh cho 30°, 45°, 60°, 90°, 180°, hoặc thậm chí Đường vòng chữ U và đường tròn. Bán kính quay có thể được điều chỉnh dựa trên kích thước sản phẩm và không gian có sẵn, tối đa hóa hiệu quả bố trí nhà máy. -

Chuyển đổi mượt mà

Hệ thống băng tải cong chất lượng cao đảm bảo vật liệu di chuyển trơn tru quanh khúc cua không bị đổ, tắc nghẽn hoặc hư hỏng—đặc biệt quan trọng đối với các sản phẩm thực phẩm dễ vỡ hoặc có hình dạng không đều.

👉 Ví dụ: Dây chuyền đóng chai đồ uống sử dụng băng tải cong để vận chuyển chai giữa các trạm chiết rót và đóng nắp mà không bị tràn. -

Nhiều biến thể

Bao gồm đường cong đai, đường cong đĩa xích, đường cong đai nhựa mô-đun và đường cong con lăn. Đối với các ứng dụng thực phẩm, vật liệu như thép không gỉ hoặc nhựa dùng trong thực phẩm được sử dụng vì độ bền và vệ sinh. -

Tối ưu hóa bố cục

Băng tải cong giúp các nhà máy thiết kế dây chuyền sản xuất tự động, nhỏ gọn hơn, giảm thiểu việc xử lý thủ công và tăng cường luồng hoạt động.

👉 Ví dụ: Trong sản xuất bánh ngọt, chúng dẫn hướng các sản phẩm nướng từ lò nướng đến khu vực làm mát và đóng gói theo một đường đi liền mạch.

🍽️ Tập trung ứng dụng: Khả năng thích ứng của băng tải cấp thực phẩm

Trong ngành công nghiệp thực phẩm, khả năng thích ứng của băng tải là nhiều hơn chỉ là vấn đề không gian—đây là yếu tố quan trọng trong việc duy trì vệ sinh, khả năng truy xuất nguồn gốc và hiệu quả.

✅ Điều gì làm cho máy vận chuyển thực phẩm trở nên đặc biệt?

-

Vật liệu được chứng nhận đạt tiêu chuẩn thực phẩm

Chỉ sử dụng Vật liệu không độc hại, tuân thủ FDA giống Thép không gỉ 304/316L, Và Dây đai PU/PVC an toàn khi tiếp xúc trực tiếp với thực phẩm. -

Thiết kế mở, dễ rửa

Các cấu trúc được xây dựng bằng không có vùng chết, bề mặt dốc để thoát nước, Và Linh kiện kín đạt chuẩn IP để chịu được vệ sinh hàng ngày. -

Tích hợp chặt chẽ với HACCP và Tiêu chuẩn An toàn

Tất cả các đường dẫn băng tải phải hỗ trợ phòng ngừa lây nhiễm chéo, dễ vệ sinh và có thể truy xuất nguồn gốc trong kiểm tra an toàn thực phẩm. -

Bố trí nhà máy Harmony

Bằng cách kết hợp các băng tải thẳng, nghiêng và cong, các nhà máy thực phẩm có thể tạo ra dây chuyền sản xuất liên tục, khép kín chuyển nguyên liệu từ khâu chuẩn bị đến khâu đóng gói mà không có sự thỏa hiệp.

🧾 Kết luận

Các nhà máy hiện đại đòi hỏi nhiều hơn là chỉ vận chuyển vật liệu cơ bản—chúng đòi hỏi hệ thống băng tải có thể tùy chỉnh, hiệu quả và hợp vệ sinh thích ứng với nhu cầu về không gian, luồng và quy trình.

Cảm ơn công nghệ băng tải thẳng, nghiêng và cong, các hệ thống ngày nay có thể điều hướng bất kỳ môi trường sản xuất nào—tiết kiệm không gian, tăng năng suất và đảm bảo an toàn thực phẩm.

Tại [Tên công ty của bạn], chúng tôi hiểu rằng mỗi cách bố trí nhà máy là duy nhất. Đó là lý do tại sao chúng tôi chuyên thiết kế giải pháp băng tải phù hợp phù hợp với không gian, vật liệu, nhu cầu vệ sinh và mục tiêu tự động hóa của bạn.

📞 Hãy thiết kế băng tải phù hợp cho cơ sở của bạn

Bạn đang muốn xây dựng một hệ thống băng tải phù hợp hoàn hảo với bố trí nhà máy của mình?

Bạn có muốn kết hợp vệ sinh, hiệu quả và tối ưu hóa không gian trong cùng một giải pháp không?

👉 Liên hệ với đội ngũ kỹ sư của chúng tôi hôm nay để được tư vấn miễn phí.

📩 Hãy gửi cho chúng tôi bản vẽ hoặc ảnh bố trí của bạn—chúng tôi sẽ giúp thiết kế một kế hoạch băng tải hoàn chỉnh.

📞 Bạn muốn trò chuyện? Hãy gọi trực tiếp cho chúng tôi để trao đổi với các chuyên gia băng tải của chúng tôi.