What Is Sprocket ?

Sprockets are essential components in modern food processing and automation machinery, designed to ensure precise, hygienic, and reliable material handling. Fill Package’s sprockets are specifically tailored to meet stringent food industry standards, enhancing overall production efficiency and reliability.

Principio de funcionamiento

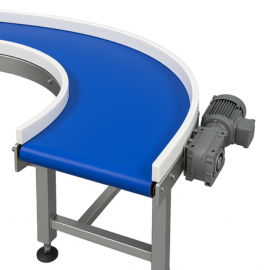

A conveyor sprocket transmits rotational motion from a motor to a conveyor chain. Precision-machined teeth engage smoothly with the conveyor chain rollers, converting rotational energy into linear motion. This design ensures minimal friction, accurate chain alignment, reduced vibration, and quiet operation, all of which are vital in food processing environments.

Detailed Industry Applications

1. Food Processing Industry

-

Hygiene-Focused Design: Food-grade stainless steel sprockets prevent bacterial growth, ideal for meat processing, dairy production, snack food packaging, and beverage bottling.

-

Application Example: On a dairy product conveyor line, electropolished sprockets ensure easy sanitation, significantly reducing downtime during daily cleaning procedures.

2. Bakery and Confectionery

-

Material Compatibility: PTFE-coated sprockets provide non-stick surfaces suitable for conveyors handling sticky substances such as chocolate, caramel, or dough.

-

Application Example: A confectionery manufacturer utilizes PTFE-coated sprockets to eliminate product adhesion issues, ensuring smooth operation and minimal waste.

3. Automated Packaging Lines

-

Precision and Speed: Balanced sprockets with optimized tooth profiles enable precise timing and synchronization essential for automated packaging equipment.

-

Application Example: High-speed snack packaging lines employ precision-balanced sprockets to maintain consistent packaging rates, reducing product loss and increasing output.

4. Pharmaceutical and Chemical Processing

-

Corrosion Resistance: High-grade stainless steel sprockets resist harsh chemicals and rigorous cleaning agents, ensuring reliability in pharmaceutical manufacturing and chemical processing.

-

Application Example: A pharmaceutical conveyor system utilizes corrosion-resistant sprockets to handle chemical cleaning routines without degradation, maintaining sterile conditions.

5. Seafood and Poultry Processing

-

Robustness and Durability: Hardened stainless steel sprockets withstand heavy loads and continuous operation under cold and wet conditions typical in seafood and poultry plants.

-

Application Example: Poultry processing lines use hardened sprockets to maintain continuous operation despite repeated washdowns and harsh conditions, improving overall plant efficiency.

Sprocket Key Features

- Precision Manufacturing: High accuracy CNC machining ensures perfect tooth alignment, reducing wear and extending the service life.

- Food-Grade Materials: Constructed using 304 and 316L stainless steel or FDA-approved plastics (POM, Nylon) for hygienic food handling.

- Easy Clean Design: Polished surfaces and rounded corners eliminate contamination points, complying with strict hygiene regulations.

- Flexible Specifications: Available from 8 to 200 teeth, accommodating diverse conveyor speeds and loads commonly found in food automation.

Industry Applications

Food Processing & Packaging Solutions

Our conveyor sprockets fully comply with FDA and USDA food safety guidelines, ensuring reliable operation in high-hygiene environments:

-

Diseño higiénico: Smooth transitions, no crevices, easy cleaning.

-

Easy Maintenance: Quick disassembly for thorough sanitation.

-

Specialized Coatings: PTFE coatings for sticky and sugary product handling.

Automation Machinery Solutions

Precision sprockets tailored for automated packaging systems and robotics:

-

High-Speed Capability: Balanced for speeds up to 15 m/s, maintaining stable operation.

-

Integration Ready: Compatible with Industry 4.0 systems, providing real-time performance data.

Installation and Maintenance Guidelines

- Precise Installation: Ensure sprocket alignment with shaft concentricity within 0.1 mm to prevent premature wear.

-

Regular Lubrication: Schedule routine lubrication based on manufacturer guidelines to optimize performance and extend equipment lifespan.

-

Inspection and Adjustment: Regularly inspect sprockets for tooth wear, adjust chain tension accordingly, and replace worn components promptly.

Quality and Certifications

-

ISO 9001 Certified: Demonstrates consistent product quality and adherence to international manufacturing standards.

-

FDA & USDA Compliance: Guarantees suitability for direct food contact applications, meeting strict international hygiene regulations.

Material Comparison: Carbon Steel vs Stainless Steel vs Plastic (Nylon/POM)

| Material | Ventajas | Desventajas | Typical Application |

|---|---|---|---|

| Carbon Steel | – High strength and wear resistance – Cost-effective |

– Prone to corrosion in wet or food environments – Heavier |

Heavy-duty conveyors in dry, industrial settings |

| Stainless Steel (304/316L) | – Excellent corrosion resistance – FDA-compliant – Hygienic and durable |

– More expensive – Slightly harder to machine |

Food processing, pharmaceutical, seafood, beverage industries |

| Plastic (Nylon, POM) | – Lightweight – Low noise – Corrosion-resistant – Economical for light loads |

– Lower load capacity – Sensitive to temperature extremes |

Light-load conveyors, high-speed packaging, dry food handling |

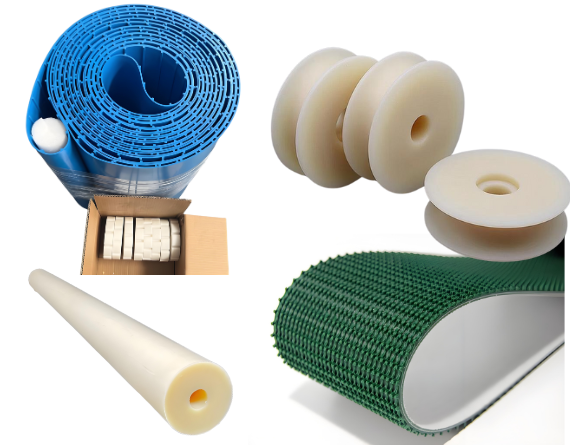

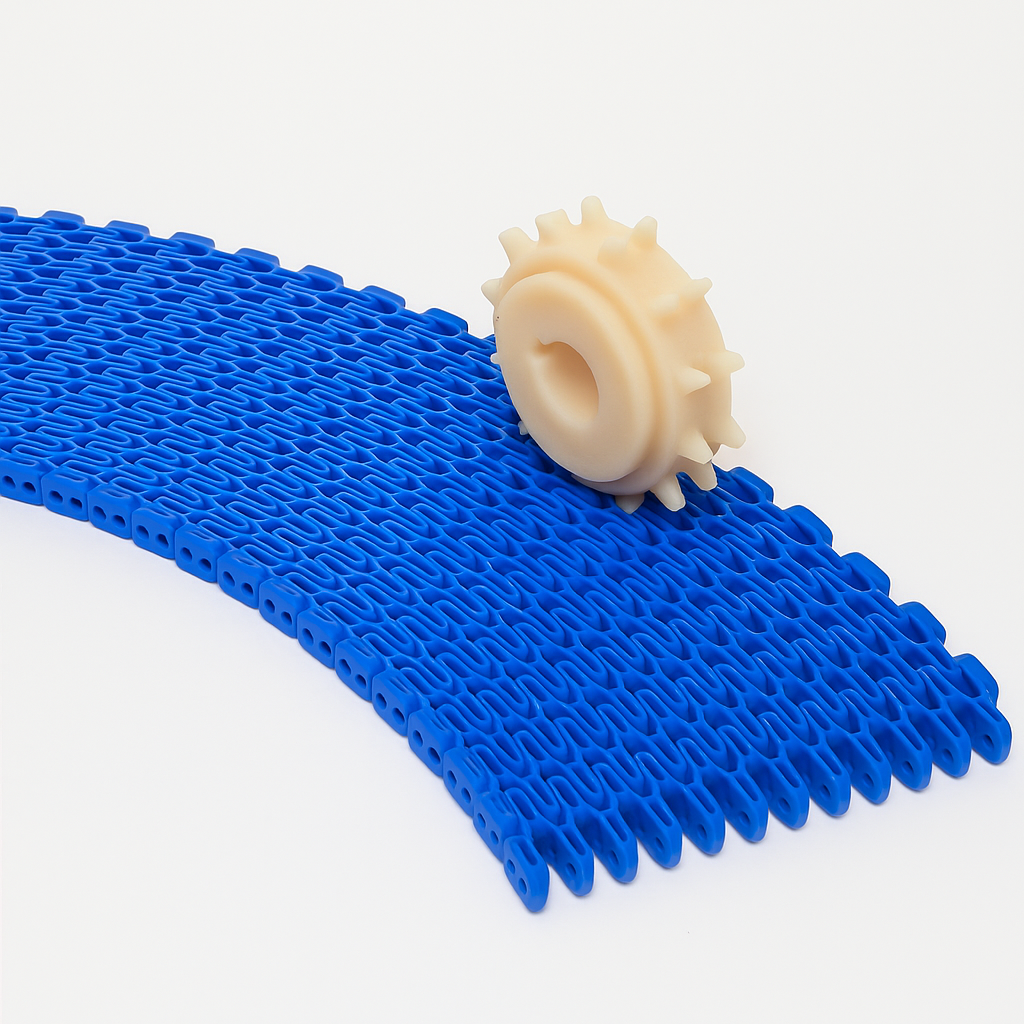

PU/PVC Belt Conveyors – Always Use Plastic Sprockets

Para PU belt y PVC belt conveyors commonly used in food packaging lines (such as snack sorting or frozen food weighing systems), plastic sprockets—typically made of Nylon (PA) o POM (acetal)—are the industry standard. These belts must not be paired with metal sprockets, as the hardness of metal can damage the belt surface, leading to premature failure, misalignment, or contamination.

In these conveyors:

- Most plastic sprockets are produced through CNC machining, ensuring tighter tolerances and smooth surface finish—ideal for sanitary environments.

- Some idler rollers may be made with injection-molded plastic, which is more cost-effective in volume but tends to have shorter lifespan due to lower-grade raw materials commonly used in mass production.

- CNC-cut plastic sprockets are more durable, precise, and do not require molds, making them ideal for small batch customization.

Modular Plastic Belt Conveyors – Match Pitch, Bore, and Tooth Count

En modular plastic belt conveyors (often used in baked goods packaging, fruit sorting, or tray loading), the sprocket design depends entirely on the belt pitch y chain structure. The sprocket must precisely match:

- Tooth count (which affects pitch diameter and tension),

- Bore size (to fit the central shaft),

- And the profile type of the modular belt.

These sprockets are often made of Nylon or POM, and available in both molded y CNC-machined versions:

- Molded sprockets are cheaper and suitable for general applications, but their raw material quality varies by supplier, and may lead to cracks or deformation after extended use.

- CNC-machined sprockets, cut from virgin material bars, offer higher precision and durability, and can be produced in low volumes without tooling cost.

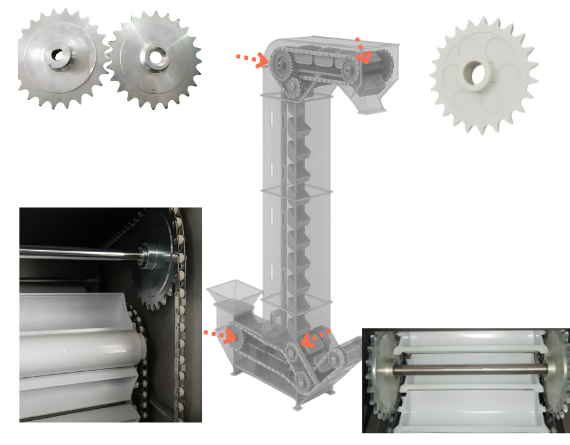

Z-Bucket Elevators – Choose Based on Load and Budget

Z-shaped bucket elevators, used for vertical lifting of granules, snacks, or frozen vegetables, have unique sprocket selection logic:

- El drive sprocket (located at the motor end) is always metal, due to its role in torque transfer and durability.

- El idler sprockets can be either plastic or metal, depending on budget and expected service life.

Here’s how to choose:

- Plastic idler sprockets (often nylon or POM) are quieter and cheaper, suitable for lighter loads and budget-sensitive projects. Compared with carbon steel sprockets, they can cost 50–70% less.

- Carbon steel sprockets are a popular middle-ground—more durable than plastic, yet cheaper than stainless steel, making them a common choice in general-purpose food conveying systems.

- Stainless steel sprockets, while offering the highest corrosion resistance and longevity, can be up to 4x more expensive than plastic—used mostly in high-end or washdown applications.

Producto relacionado

Choose stainless steel (preferably 316L) for washdown areas or if the sprocket will directly contact food. Use plastic sprockets (POM/Nylon) for dry goods or in areas where weight reduction and cost savings are a priority.

316L has higher molybdenum content, offering superior resistance to salt, acidic environments, and aggressive cleaning agents—ideal for seafood, dairy, or pharmaceutical use. 304 is suitable for general food-grade use.d.

Only under light-to-medium load and controlled environments. For high-load or high-temperature areas, stainless steel is recommended to avoid deformation or accelerated wear.

With proper maintenance, stainless steel sprockets can last 20,000–50,000 hours, while plastic ones typically last 5,000–20,000 hours, depending on load, speed, and cleaning frequency.

Visual inspection every 2–4 semanas, and full maintenance (including chain alignment, lubrication, and tension check) every 3–6 months is recommended

Yes, we offer full non-standard customization for bore size, tooth profile, keyway type, material, and coatings. Lead time for custom orders is typically 2–4 semanas.

For stainless steel: use hot water or food-grade alkaline cleaners, followed by disinfection. For plastic: avoid high-temp washing (>80°C) and use mild detergent to prevent warping.

Not recommended unless used in non-contact zones or sealed systems. Carbon steel corrodes easily, posing contamination risks and hygiene concerns in food production.

Our sprockets meet FDA, USDA, y ISO 9001 standards. Stainless steel versions can be provided with material traceability certificates y surface roughness reports upon request.

Our high-precision sprockets (balanced to G2.5 level) can operate up to 15 m/s, depending on load, chain type, and system design.