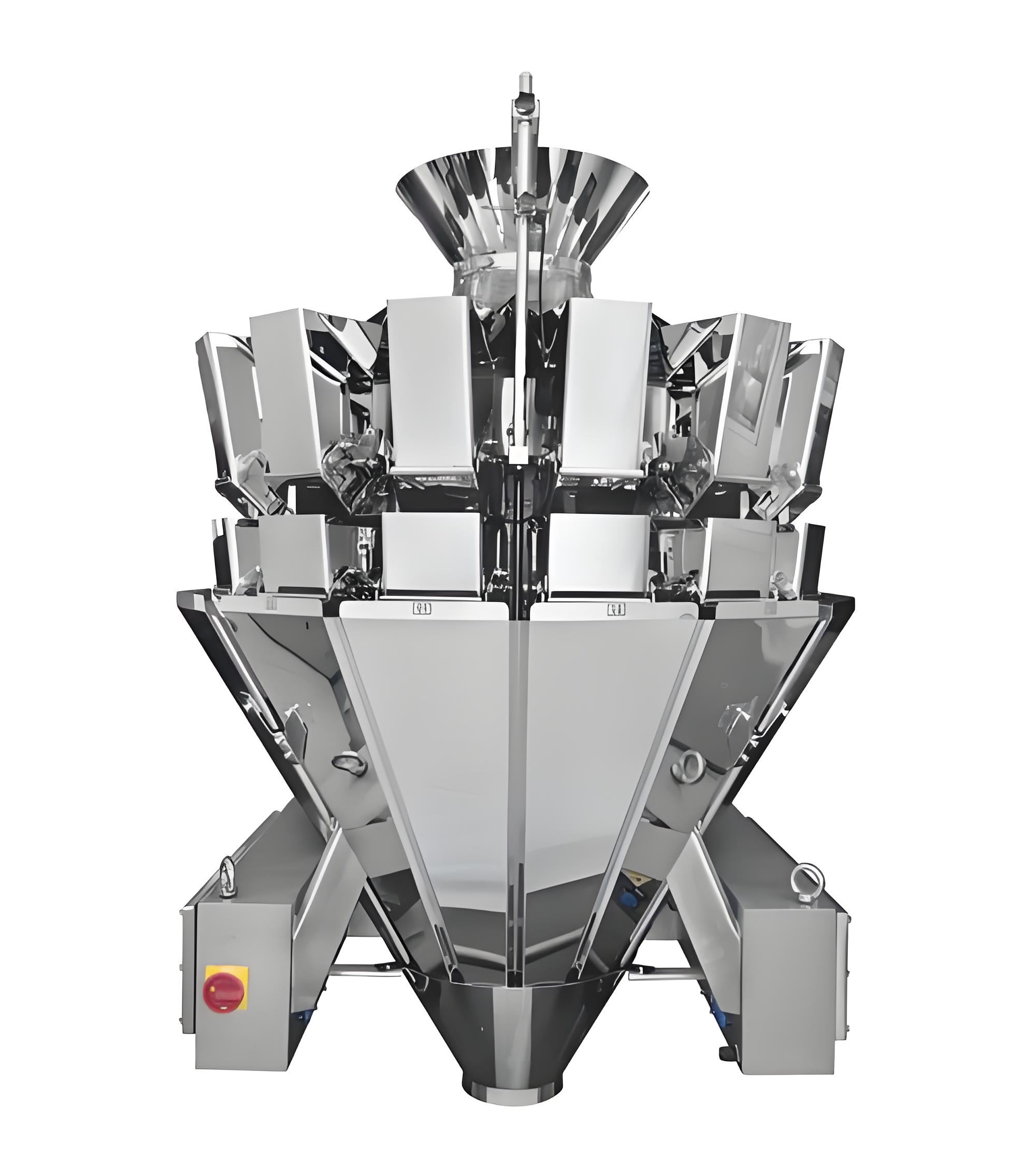

En la producción industrial moderna, pesadoras multicabezal Sirven como equipos de pesaje eficientes y precisos, ampliamente utilizados en los sectores alimentario, farmacéutico y químico. Al optimizar la distribución y las combinaciones de materiales, mejoran significativamente la eficiencia del envasado y la precisión del pesaje. Sin embargo, a menudo se requieren configuraciones adicionales personalizadas para satisfacer los requisitos específicos de la industria y las características únicas de los materiales, abordando así los desafíos comunes de producción y mejorando significativamente la adaptabilidad y la productividad de los equipos.

Este artículo ofrece una exploración detallada de varias configuraciones adicionales comunes de básculas combinadas, analizando sus ventajas únicas en diversos escenarios de aplicación para ayudarle a seleccionar la mejor solución para sus necesidades de producción. No dude en contactarnos para obtener información más detallada y asesoramiento personalizado.

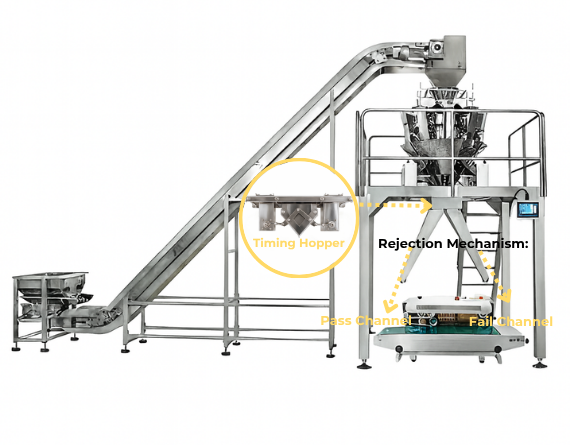

1. Tolva de sincronización y mecanismo de rechazo

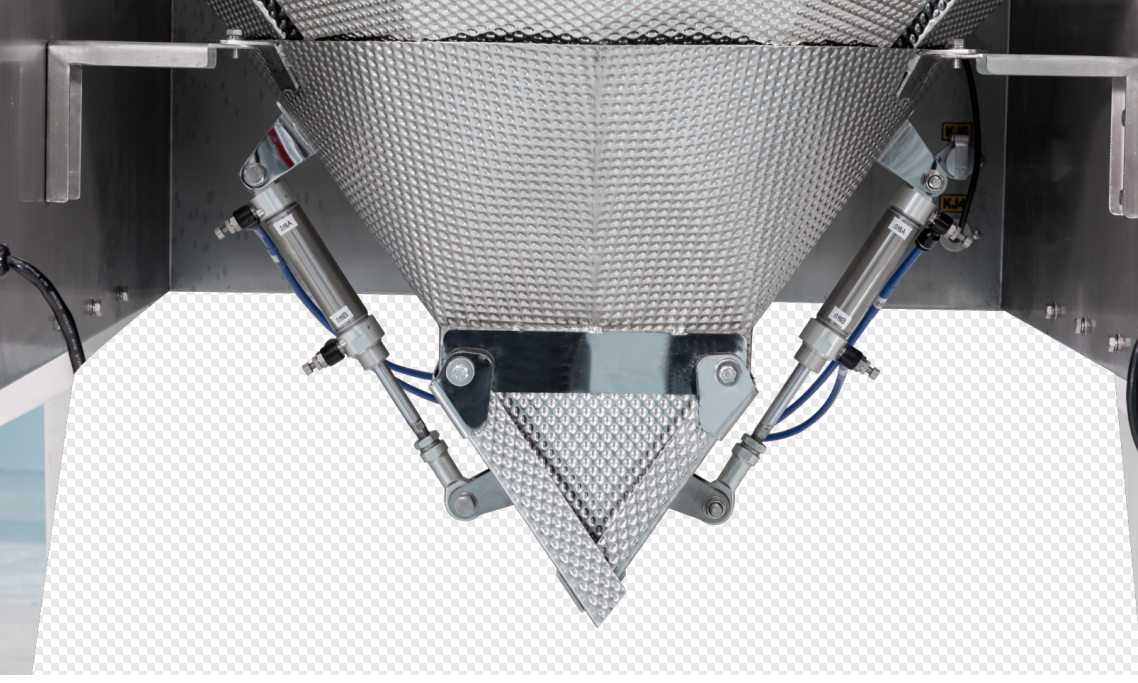

La tolva temporizada almacena temporalmente los materiales pesados de la báscula combinada y los libera rápidamente al recibir una señal de la envasadora, lo que aumenta significativamente la velocidad y la eficiencia del envasado. Normalmente accionados por cilindros neumáticos, como los de AirTac, garantizan acciones precisas y fiables.

Aplicaciones:

- Embalaje de alta velocidad: En industrias como la de snacks y dulces, las tolvas recolectoras mejoran la velocidad de envasado en más de 5%.

- Materiales esponjosos o irregulares: Adecuado para patatas fritas o snacks inflados, evitando bloqueos y garantizando un flujo suave.

- Embalaje de materiales mixtos: Ideal para frutos secos mixtos o dulces de múltiples sabores, asegurando una mezcla uniforme.

Mecanismo de rechazo:

- Elimina productos de calidad inferior: Elimina automáticamente productos con pesos inexactos para mantener una calidad constante del producto.

- Función de clasificación: También puede separar productos de diferentes especificaciones o grados.

- Previene bloqueos y desbordamientos: Dirige el flujo de material de manera eficiente, manteniendo limpias las áreas de producción.

2. Puerta de anillo y puerta guía calentada

Ring Gate dirige los materiales hacia las tolvas de pesaje, evitando derrames y manteniendo la limpieza.

Aplicaciones:

- Orientación sobre materiales y prevención de derrames: Controla el flujo del producto durante los procesos de vibración y caída.

- Precisión de pesaje mejorada: Garantiza una distribución uniforme del material para una mejor precisión.

Puerta de anillo calentada:

- Materiales pegajosos: Reduce la adherencia de dulces, frutas en conserva y carnes.

- Ambientes de baja temperatura: Evita la rigidez del material en condiciones de frío.

- Ambientes húmedos: Reduce la humedad de la superficie, evitando que se pegue.

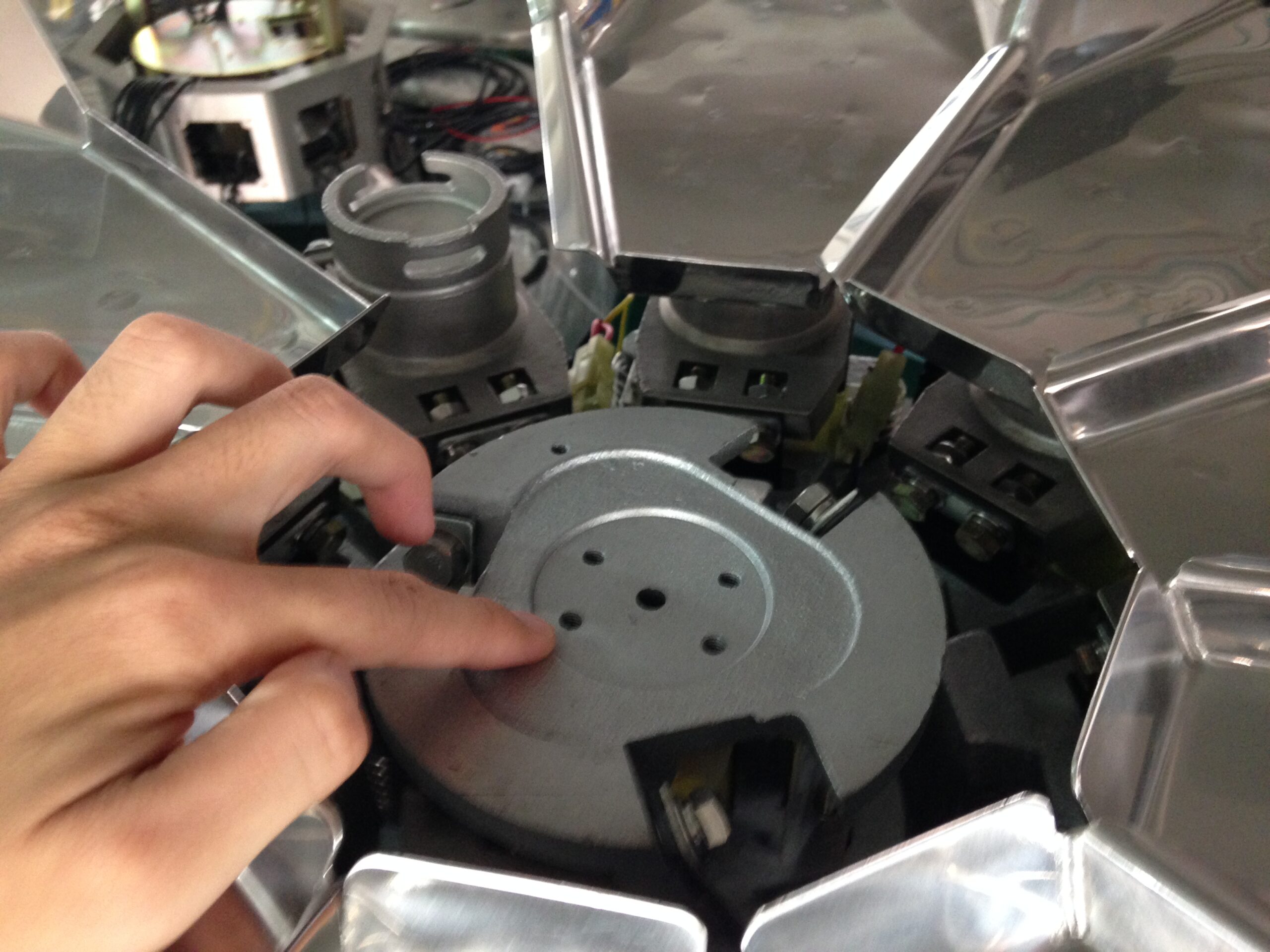

3. Célula de carga de vibración principal

La celda de carga de pesaje por vibración principal mide con precisión el peso del material en la bandeja de vibración principal, ajustando la frecuencia y la amplitud de la vibración para lograr una distribución uniforme.

Aplicaciones:

- Distribución uniforme del material: Equilibra la alimentación de material, mejorando la precisión del pesaje.

- Control óptimo de la alimentación: Proporciona control de circuito cerrado, manteniendo una alimentación continua y estable.

- Adaptabilidad a múltiples materiales: Adecuado para diversos materiales, desde gránulos que fluyen libremente hasta polvos pegajosos.

- Reducción de residuos: Previene desbordamientos y bloqueos, mejorando la rentabilidad.

- Automatización mejorada: Proporciona ajustes adaptativos e inteligentes a las condiciones del material.

4. Recubrimiento de teflón (de una y dos caras)

Los recubrimientos de teflón (PTFE) mejoran el flujo del material al reducir la adhesión.

Aplicaciones:

- Materiales altamente pegajosos: Evita obstrucciones con dulces, productos congelados y sustancias aceitosas.

- Materiales corrosivos: Protege las superficies, alargando la vida útil del equipo.

- Fácil limpieza: Simplifica el mantenimiento y reduce el tiempo de inactividad.

Una cara vs. dos caras:

- De una sola cara: Solución rentable para adherencia moderada.

- De dos caras: Ideal para situaciones de alta adherencia o limpieza frecuente, mejorando la higiene general y la durabilidad.

5. Bandeja de alimentación principal giratoria (con/sin convertidor de frecuencia)

Una bandeja giratoria dispersa uniformemente los materiales desafiantes.

Aplicaciones:

- Formas irregulares: Evita el apilamiento y garantiza un flujo suave de material para fideos y verduras.

- Mayor eficiencia de alimentación: Ideal para líneas de producción de alta velocidad.

- Daños materiales reducidos: Minimiza la fricción y el impacto en productos frágiles.

Beneficios del convertidor de frecuencia:

- Velocidades ajustables: Adapta las tasas de alimentación con precisión, optimizando el rendimiento y la eficiencia energética.

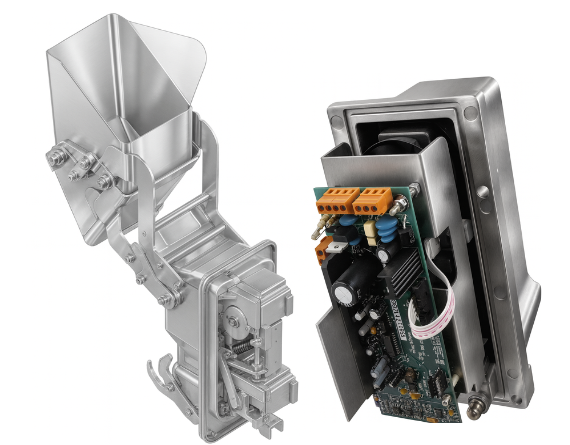

6. Unidad de control de peso adicional

Agrega funcionalidad de pesaje secundario para lograr una precisión rigurosa.

Aplicaciones:

- Productos sensibles a la precisión: Garantiza el cumplimiento de estrictos estándares de peso.

- Reducción de errores: Identifica y corrige errores acumulativos.

- Cumplimiento mejorado del producto: Mejora la consistencia del producto y reduce el desperdicio.

- Seguimiento de datos: Facilita el control de calidad a través de análisis de datos detallados.

7. Acero inoxidable Bastidor base y carcasa de celda de carga de pesaje

La actualización del marco base y la carcasa de la celda de carga de pesaje de aluminio a acero inoxidable mejora la resistencia a la corrosión y la higiene.

Aplicaciones:

- Ambientes corrosivos: Ideal para procesamiento de mariscos e industrias químicas.

- Alimentos y productos farmacéuticos: Cumple estrictos requisitos de limpieza.

- Durabilidad: Proporciona una resistencia superior y costos de mantenimiento reducidos.

8. Actualice a acero inoxidable 316

Ideal para el manejo de materiales altamente corrosivos.

Aplicaciones:

- Productos de alta salinidad: Adecuado para alimentos salados y mariscos.

- Sustancias ácidas o alcalinas: Excelente resistencia en la industria farmacéutica y química.

- Mayor durabilidad: Reduce la frecuencia de reemplazo y mantenimiento.

9. Chasis elevado y ángulos de rampa más pronunciados

Mejora el flujo de material y la comodidad operativa.

Aplicaciones:

- Productos resistentes al flujo: Mejora el movimiento del material para productos pegajosos o irregulares.

- Flexibilidad de integración: Ofrece espacio adicional para equipo auxiliar.

- Accesibilidad de mantenimiento: Proporciona un mejor acceso para la limpieza y la resolución de problemas.

10. Dispositivo anticondensación (ventilación o calefacción)

Evita la condensación en ambientes húmedos o de temperatura variable.

Aplicaciones:

- Ventilación: Adecuado para ambientes constantemente húmedos.

- Calefacción: Ideal para entornos con fluctuaciones significativas de temperatura, como cámaras frigoríficas.

11. Dispositivo en la bandeja de descarga

Protege los productos contra impactos durante la descarga.

Aplicaciones:

- Materiales frágiles: Reduce la rotura de patatas fritas y productos congelados.

- Materiales de alto valor: Minimiza las pérdidas económicas por rotura.

- Reducción de ruido: Mejora el entorno de trabajo al absorber el ruido de impacto.

12. para productos en polvo

Garantiza una manipulación precisa y sin fugas del polvo.

Aplicaciones:

- Productos en polvo: Ideal para azúcares, harinas y polvos químicos.

- Prevención de fugas: Mantiene la limpieza y minimiza el desperdicio.

- Mejora de la precisión: Garantiza un pesaje y una entrega de material consistentes.

Conclusión

Personalización básculas combinadas Con las configuraciones adecuadas, se mejora significativamente la productividad, la precisión y la calidad del producto. Ya sea para manipular productos delicados, gestionar sustancias pegajosas, garantizar los estándares de higiene o mejorar la adaptabilidad ambiental, cada configuración aborda necesidades de producción específicas. Le animamos a contactar con nuestros especialistas para explorar soluciones a medida que maximicen su eficiencia operativa y el valor de sus productos..