Introdução: Vamos construir o transportador certo juntos

Você atua no setor de produção de alimentos e está se perguntando como escolher o transportador certo para seus produtos exclusivos?

Ouvimos muito essa pergunta. Como profissional fabricante de máquinas de processamento de alimentos, ajudamos empresas dos setores de panificação, salgadinhos, carnes, produtos hortifrutigranjeiros, congelados e bebidas a encontrar sistemas de transporte personalizados que atendam às suas necessidades, não apenas técnicas, mas também econômicas e higiênicas.

Neste guia, detalharemos os pontos fortes e os melhores casos de uso para oito tipos de transportadores de alimentos. Seja o seu foco o manuseio suave, a elevação vertical, a facilidade de limpeza ou o design que economiza espaço, nós o ajudaremos a tomar uma decisão informada. E se você ainda estiver indeciso no final, estender a mão—estamos aqui para ajudar com consultoria especializada e soluções de transportadores personalizadas.

1. Transportadores de correia – Versátil, confiável e suave

Melhor para: Ampla gama de produtos, incluindo produtos de panificação, produtos agrícolas e laticínios, e itens embalados.

Por que nossos clientes escolhem isto:

- Projetado com Correias de PU, PVC ou aço inoxidável que atendem aos padrões internacionais de segurança alimentar.

- Processa desde ingredientes em pó até doces delicados.

- Saias laterais e travas opcionais permitem o transporte em inclinação, evitando derramamentos.

- O design modular torna a limpeza rápida e fácil, economizando tempo entre as trocas de produtos.

👉 Ótima escolha se você está procurando transporte suave e contínuo de produtos uniformes ou mistos em disposição horizontal ou inclinada.

2. Elevadores de caçamba tipo Z – Quando você precisa de elevação vertical sem derramamentos

Melhor para: Grãos, farinha, açúcar, doces, grãos de café.

Por que nossos clientes escolhem isto:

- Fornece um ambiente selado para elevação vertical, reduzindo poeira e prevenindo contaminação.

- Baldes personalizáveis (de plástico ou aço inoxidável) para atender a diversas densidades e vazões.

- Ideal para conectar funis no nível do solo a estações elevadas de embalagem ou mistura.

👉 Escolha esta opção se o seu processo precisar levantar produtos verticalmente com espaço mínimo e saneamento máximo.

3. Transportadores Vibratórios – Eficiente e multifuncional

Melhor para: Salgadinhos, cereais, nozes, produtos e itens pré-lavados ou congelados.

Por que nossos clientes escolhem isto:

- Move suavemente os produtos para a frente usando vibrações de alta frequência.

- Pode peneirar, resfriar, revestir ou secar produtos durante o transporte.

- Estrutura simples e aberta é fácil de limpar e manter.

👉 Procurando fazer mais do que apenas mover produtos na sua linha? Transportadores vibratórios são perfeitos para processamento integrado.

4. Transportadores Fastback – Transporte horizontal ultra suave

Melhor para: Itens frágeis ou revestidos, como batatas fritas, biscoitos, carnes e folhas verdes.

Por que nossos clientes escolhem isto:

- O movimento patenteado de “avanço lento-retorno rápido” significa praticamente sem vibração ou salto—protegendo itens frágeis contra danos.

- O design aberto em aço inoxidável é fácil de lavar e higienizar.

- Ideal para descargas multiponto, espalhamento suave e integração com sistemas de tempero ou pesagem.

- Ultra silencioso e baixa manutenção—um favorito em instalações modernas e higiênicas.

👉 Se o seu produto for frágil ou pegajoso, ou se sua instalação tiver protocolos de higiene rigorosos, este é o seu transportador.

5. Transportadores de rolos – Ótimos para caixas, sacolas e embalagens prontas

Melhor para: Caixas, engradados, engradados e bandejas em áreas de fim de linha e logística.

Por que nossos clientes escolhem isto:

- Suporta ambos opções de gravidade e energia para transporte flexível.

- Manutenção simplificada e rolos fáceis de substituir.

- Frequentemente usado em combinação com sensores, desviadores e robôs de empilhamento.

👉 Perfeito se você está procurando um solução simples e robusta para mover produtos embalados ou preparar itens para envio.

6. Transportadores de placas de corrente – Durável, potente e adaptável

Melhor para: Recipientes de alimentos pesados ou de formato irregular, especialmente em ambientes úmidos ou de alta temperatura.

Por que nossos clientes escolhem isto:

-

Durável placas de metal ou plástico apoiado por um sistema de esteiras de corrente.

-

Pode lidar com inclinações, declives ou caminhos curvos com facilidade.

-

Confiável em carne, frutos do mar e bebidas operações devido à sua estrutura resistente à corrosão.

👉 Use isto quando o peso do produto e a complexidade do layout exigirem um transportador resistente e duradouro.

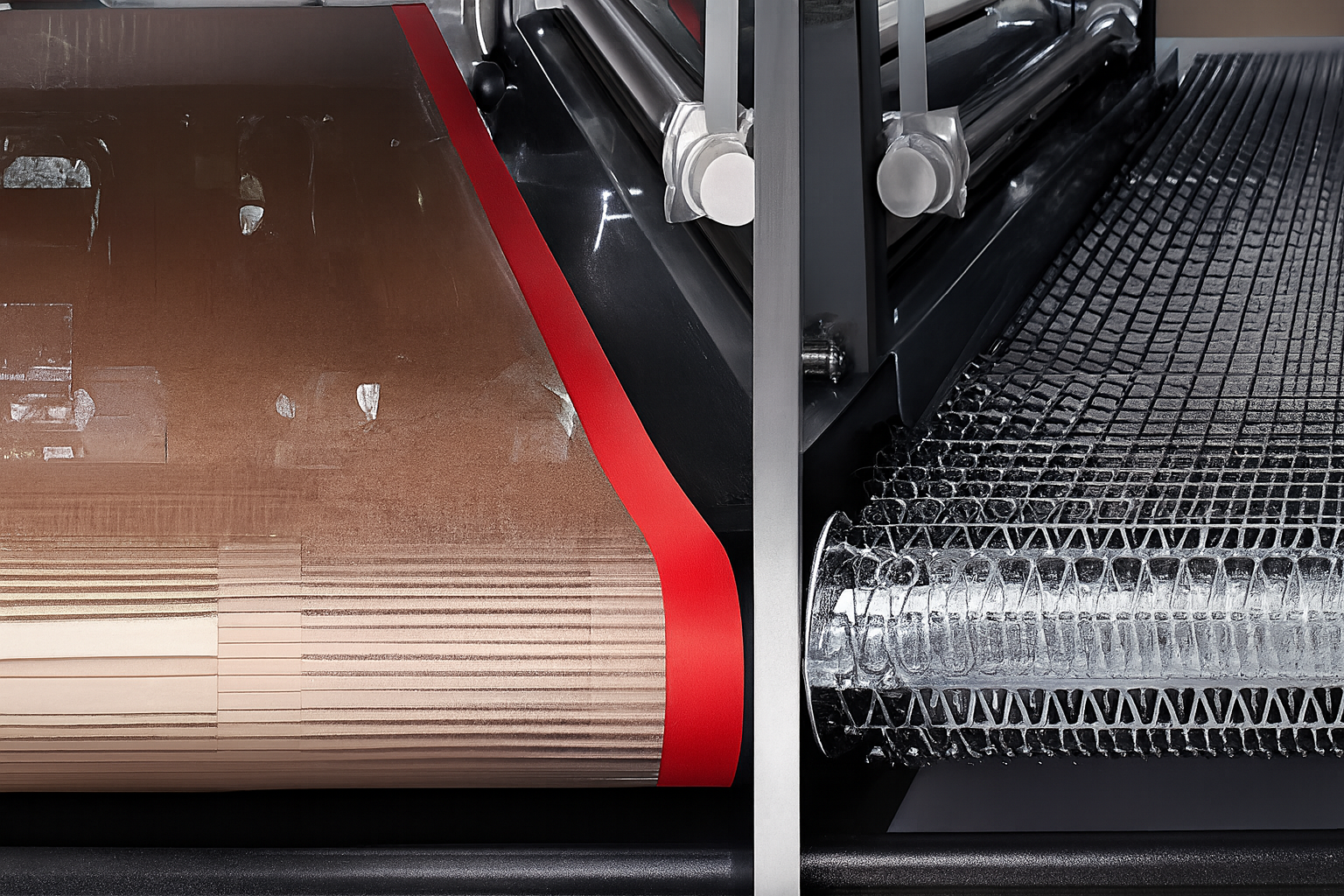

7. Transportadores de correia de malha – ideais para secagem, resfriamento ou lavagem

Melhor para: Produtos lavados, salgadinhos desengordurantes, pequenos assados, frutos do mar.

Por que nossos clientes escolhem isto:

- Excelente fluxo de ar e drenagem de água para processos como secagem ou resfriamento.

- Fácil de limpar e higienizar devido à estrutura aberta.

- Opções de malha de aço inoxidável ou plástico próprias para alimentos disponíveis.

👉 Cintos de malha brilham em operações de pós-cozimento ou pós-lavagem onde o fluxo de ar limpo e contínuo ou a drenagem são essenciais.

8. Transportadores helicoidais flexíveis – Ótimo para pós, especiarias e grãos

Melhor para: Farinha, açúcar, especiarias, proteínas em pó, ração seca para animais de estimação.

Por que nossos clientes escolhem isto:

-

O design do tubo flexível permite a fácil navegação em layouts complexos de plantas.

-

Transporte fechado protege pós sensíveis da contaminação.

-

Eficiente em termos de energia, fácil de limpar e altamente personalizável.

👉 Escolha esta opção se sua linha exigir roteamento flexível ou você manipula ingredientes em pó/granulados regularmente.

Como escolher o transportador certo: faça estas perguntas a si mesmo

1. O que você está transportando?

É frágil? Pegajoso? Molhado? Em pó? Conhecer as características físicas do seu produto é o primeiro passo.

2. Qual é o seu protocolo de higiene?

Você precisa da funcionalidade CIP (limpeza no local)? Aço inoxidável? Trocas rápidas?

3. Quais são suas metas de produtividade?

Velocidade, volume e espaçamento na linha afetarão a largura do transportador, a velocidade da correia e o projeto de descarga.

4. Você precisa de multifuncionalidade?

Precisa de resfriamento, revestimento, peneiramento ou pesagem durante a movimentação? Podemos integrar tudo isso.

5. Como é o seu layout?

Elevadores verticais? Cantos apertados? Linhas horizontais longas? Construímos sistemas que se adaptam — e não forçam — o seu espaço.

Precisa de ajuda? Vamos personalizar a sua esteira transportadora perfeita

Na [Nome da sua empresa], não apenas entregamos máquinas, mas também fazemos parceria com você para engenheiro de soluções de transporte inteligentes que tornam sua linha de produção mais eficiente, higiênica e econômica.

Deixe-nos ajudar você a projetar o sistema de transporte de alimentos ideal para o seu produto, layout e orçamento. Cuidamos de tudo, do conceito ao comissionamento.

📧 Envie-nos um e-mail: info@fill-package.com

🌐 Visite: www.fill-package.com

Ou deixe um comentário abaixo — adoraríamos saber mais sobre os desafios da sua linha de produção.