Küçük ve orta ölçekli gıda fabrikaları ve satın alma yöneticileri için mutlaka kaydedilmesi gereken bir rehber!

Giriş|Hiç bu durumlarla karşılaştınız mı?

- Bir paketleme makinesi teklifi açtım ve şu gibi terimler gördüm: çok başlı tartı, çalışma platformu, kese makinesi, Z-kovalı elevatör... ve kafanız mı karıştı?

- Tedarikçiler sürekli "Buna ihtiyacınız var" diyor ama bu size doğru gelmiyor mu?

- Makineyi satın aldınız ancak kullanımının zor veya gereksiz olduğunu mu fark ettiniz?

Endişelenmeyin. Bugünkü blog yazımızda teknik jargonu atlıyoruz; 10 pratik paketleme ekipmanı ipucu Daha akıllı kararlar almanıza ve maliyetli hatalardan kaçınmanıza yardımcı olur.

1. "Çok başlı tartım cihazı için her zaman bir platforma ihtiyacım var mı?" Kesinlikle hayır.

Birçok kişi, tartım cihazının bir VFFS makinesiyle çalışması için bir platformun zorunlu olduğunu varsayar. Bu geleneksel kurulumdur, ancak tek yol bu değildir.

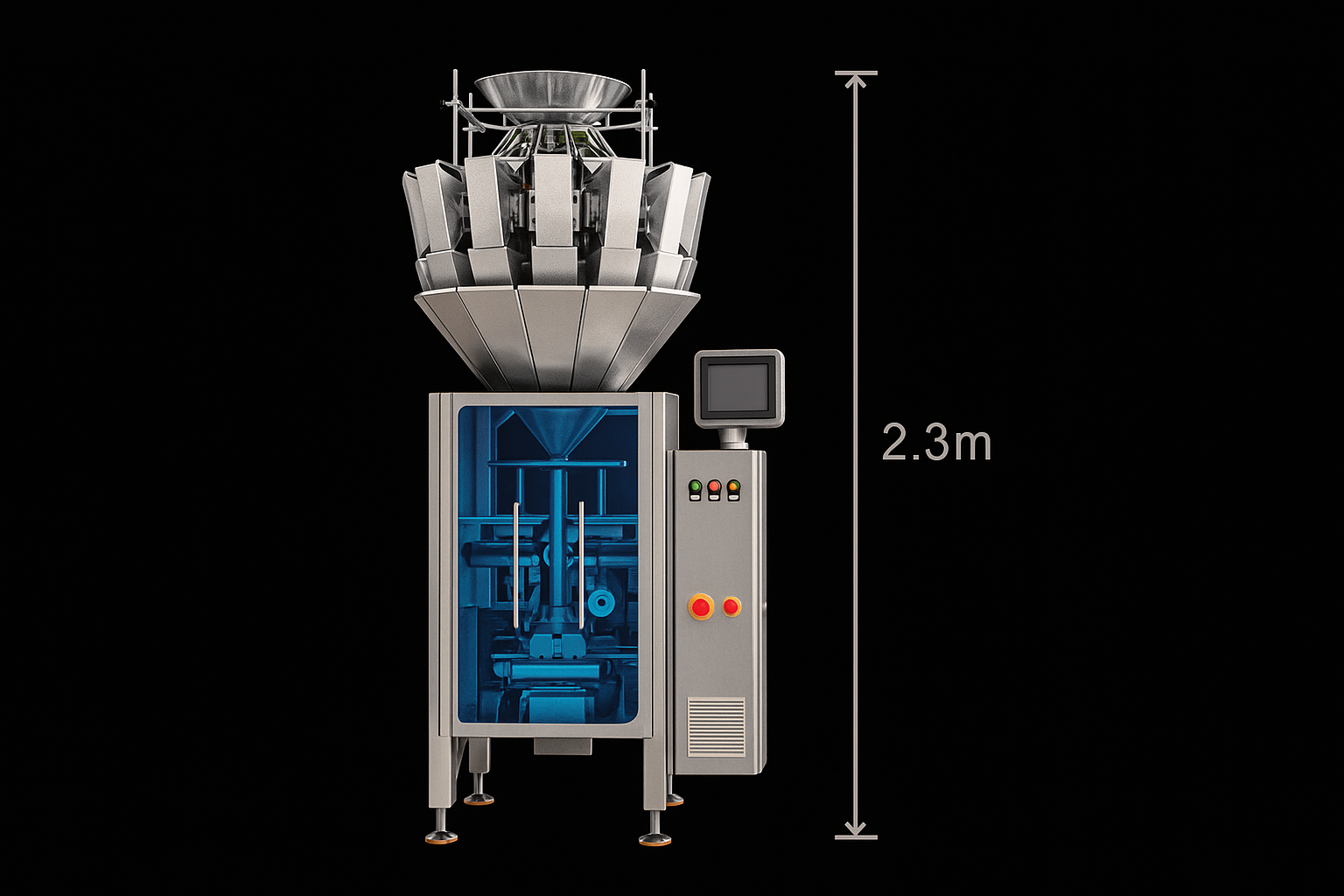

Tavan yüksekliğiniz sınırlıysa veya yatırım maliyetlerinizi düşürmeye çalışıyorsanız, hepsi bir arada entegre bir yapıyı değerlendirin. Bu yapı, tartım cihazını ve VFFS makinesini tek bir kontrol ekranıyla tek bir çerçevede birleştirir. Daha kompakt bir alanda (toplam yüksekliği 2,3 metrenin altında) aynı verimlilikle çalışabilir.

👉 Uç: Kurulumu gerçek tesis düzeninize ve iş akışınıza göre uyarlayın. "Daha büyük" her zaman "daha iyi" anlamına gelmez.

2. Yanlış bir konveyör tüm paketleme hattınızı yavaşlatabilir

Konveyörler Genellikle sonradan akla gelen bir şey olarak görülürler; ancak bu bir hatadır. Ürününüz sorunsuz ve tutarlı bir şekilde hareket etmelidir. Yanlış konveyör tipi, düşen ürünlerden tıkanıklıklara ve hijyen sorunlarına kadar her şeye neden olabilir.

Z tipi, yatay, spiral, modüler plastik kemer…her birinin en iyi şekilde kullanımı vardır.

👉 Uç: Konveyör sistemini seçmeden önce ürün akışınızı ve tesis düzeninizi planlayın. Doğru konveyör size zaman, atık ve hayal kırıklığından tasarruf sağlar.

3. Daha fazla kafa ≠ daha iyi performans. Gerçekten 24 kafaya ihtiyacınız var mı?

Daha yüksek hız anlamına geleceğini düşünerek daha fazla ağırlık almak cazip gelebilir. Ancak gerçek üretim koşulları nadiren maksimum hızlara ulaşır.

Aşırı hız, iyi kontrol edilmediği takdirde daha fazla torba hasarına veya sızdırmazlık hatalarına yol açabilir.

👉 Uç: Gösterişten ziyade tutarlılığa öncelik verin. Çalışan sayısını gerçek çıktı gereksinimlerinize ve bütçenize göre ayarlayın.

4. Paslanmaz çelik ≠ tamamen su geçirmez. Tasarımla ilgili

Ekipmanınızın paslanmaz çelikten yapılmış olması, agresif yıkamalara dayanabileceği anlamına gelmez.

Birçok arıza, suyun derzlerden, contalanmamış kapılardan veya düşük özellikli elektrik panolarından girmesiyle meydana gelir.

👉 Uç: Tedarikçinize makinenin su geçirmez muhafazaları, tahliye noktaları ve aletsiz erişim özelliği olup olmadığını sorun. Yüksek yıkamaya ihtiyacınız varsa, bunu önceden belirtin.

5. Daha küçük hazneler her zaman daha düşük maliyet anlamına gelmez

0,3 L'lik bir haznenin 1,5 L'lik bir hazneden daha ucuz olduğunu düşünebilirsiniz; çünkü daha küçüktür, değil mi? Tam olarak değil.

Daha küçük ekipmanlar genellikle daha sıkı mühendislik, daha yüksek montaj hassasiyeti ve daha fazla teknisyen saati gerektirir. Hassas tahrikler maliyetlidir.

👉 Uç: Hazne boyutunu en büyük ve en küçük ambalaj torbanıza göre seçin. Bu, hem düşük performansı hem de aşırı harcamayı önler.

6. Rulo film esnektir ve uygun maliyetlidir

Hazır poşetler güzeldir, şüphesiz. Ancak daha yüksek malzeme maliyeti ve sınırlı esneklikle gelirler.

Ürün ebatlarını veya türlerini sık sık değiştirirseniz, poşet stokları kullanılmadan birikebilir.

👉 Uç: Yüksek SKU'lu veya hızlı değişen hatlar için, VFF'ler rulo film daha ekonomiktir. önceden hazırlanmış keseler Premium markaları veya perakende satışa hazır çantaları hedeflediğinizde.

7. Hazır poşet makineleri evrensel değildir. Poşet çeşitliliği onları yavaşlatır.

Eğer çantanızın boyutu sık sık değişiyorsa, poşet makineniz buna ayak uyduramayabilir.

Standart fermuarlı poşetler veya dik duran poşetler gibi tutarlı çantalar için harikadır; ancak bugün 100 gr ve yarın 1 kg paketleyecekseniz pek ideal değildir.

👉 Uç: Sabit ve tek tip ürünler için poşet makinelerini kullanın. VFF'ler daha fazla esnekliğe ihtiyaç duyduğunuzda.

8. "Ağırlığı biz ayarladık, neden tekrar kontrol edelim?" Çünkü hatalar yine de oluyor

Hassas tartım yapan cihazlar bile ürün köprülemesi, toz birikmesi veya elektriksel sürüklenme nedeniyle hedeften sapabilir.

Kontrol tartıları, her torbanın ağırlık gerekliliklerini karşıladığından emin olmak için son güvenlik ağı görevi görür.

👉 Uç: Yüksek değerli veya düzenlemelere tabi ürünler paketliyorsanız, otomatik reddetme özelliğine sahip bir kontrol tartısına yatırım yapın. Bu, markanızı ve kârınızı korur.

9. “Makinelerimiz paslanmaz çeliktir, metal dedektörüne ihtiyacımız yoktur.” Yanlış.

Metal kirliliği yalnızca paslı parçalardan kaynaklanmaz; hammaddelerden veya iç aşınmalardan (örneğin bıçak talaşı, vidalar, gevşek kablolama) da kaynaklanabilir.

👉 Uç: Gıda, ilaç veya kozmetik ürünleri için metal dedektörleri isteğe bağlı değil, olmazsa olmazdır. HACCP ve ihracat yönetmeliklerine uygun olduğunuzdan emin olun.

10. Daha uzun konveyörler = daha iyi değer mi? Pek sayılmaz.

Daha uzun gibi görünebilir konveyör Fiyatına göre daha fazla koruma sağlar. Peki ya arızalandığında? Tamir süresi iki katına çıkar. Arıza süresi pahalı hale gelir.

👉 Uç: Konveyörleri, ayrı tahrikli 10 metrelik modüler segmentler halinde tasarlayın. Değiştirme veya bakım zamanı geldiğinde kendinize teşekkür edeceksiniz.

✅ Hatalar oluşmadan önce onları önleyin

Paketleme hattınızı yükseltmeyi veya yeni bir makine yatırımı yapmayı planlıyorsanız, size yardımcı olalım.

📩 Ürününüzün türünü ve karşılaştığınız en büyük zorluğu yorumlarda veya mesaj yoluyla paylaşın. Size özel bir çözümü ücretsiz olarak gönderelim.