Introduction: The “Pacemaker” of Your Production

When we audit underperforming packaging lines, the culprit is rarely the VFFS machine’s theoretical speed. The machine might be rated for 100 bags per minute, but the line only delivers 70.

Where did the other 30 bags go?

They were lost in the gaps, the jams, and the micro-stops caused by poor material handling. This brings us to the often-underestimated belt conveyor role in packaging lines.

Conveyors are not just passive transport devices; they are the “pacemakers” of your system. In this engineering deep-dive, we explore how optimizing your conveyor applications directly impacts packaging line efficiency.

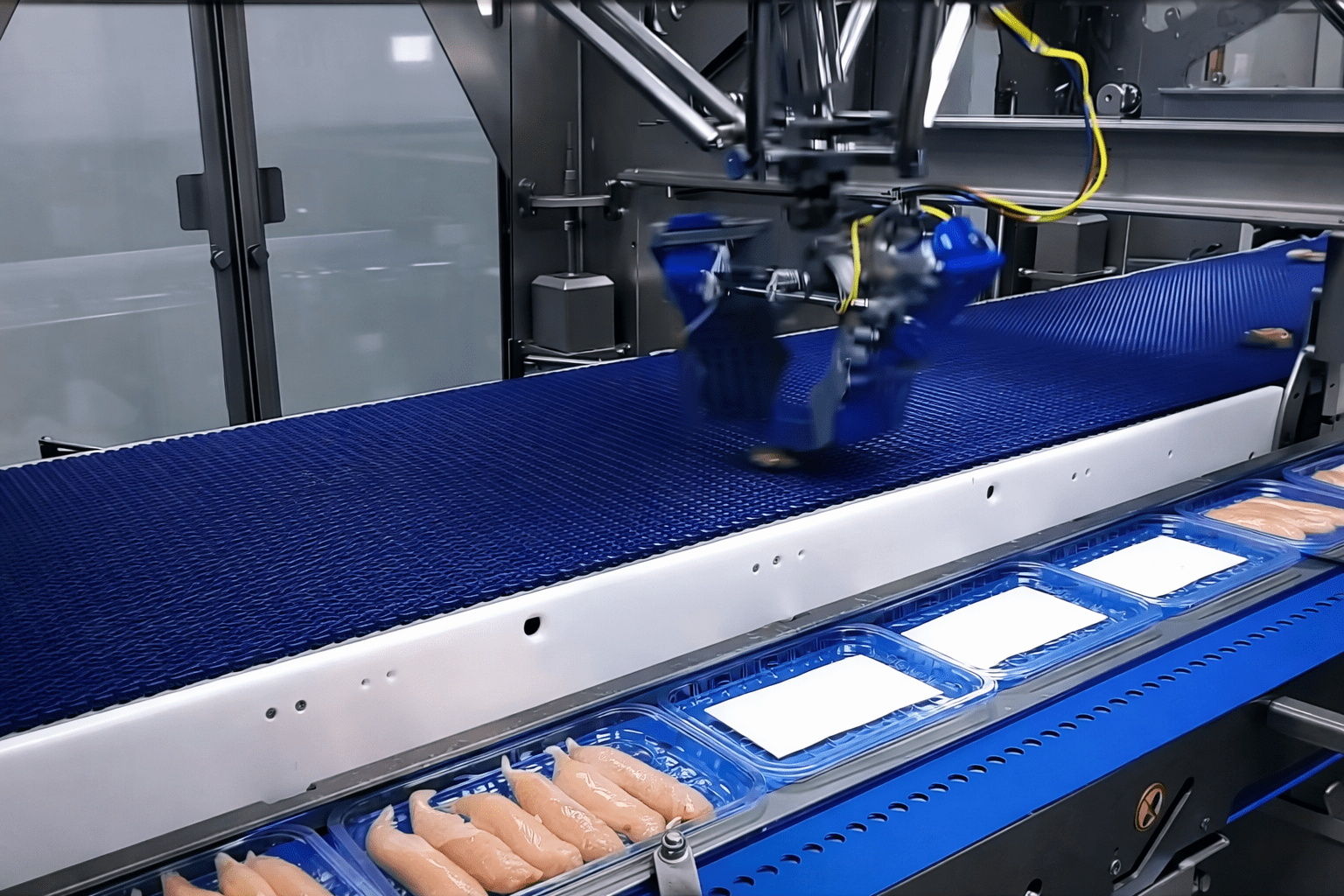

1. More Than Movement: Active Product Flow Control

A common engineering mistake is treating conveyors as simple “Point A to Point B” devices. In a high-speed line, the conveyor must actively manage the product’s behavior.

This is where product flow control becomes critical.

Gapping & Spacing: When transferring bags from a VFFS to a Check Weigher or Metal Detector, the packs cannot touch. If they do, the detector rejects them as “double packs.”

The Engineering Fix: We use variable-speed belt conveyors to pull the leading bag away from the following bag, creating a precise gap for inspection.

Stabilization: A bag dropping from a VFFS machine is unstable.

The Engineering Fix: A specifically angled incline conveyor catches the bag and settles its contents before it reaches the rotary packing table, ensuring it sits flat for casing.

2. The Power of Conveyor Integration

A belt conveyor operating in isolation is a bottleneck waiting to happen. To achieve high OEE, you need deep conveyor integration.

This means the conveyor must be electrically and logically tied to the master control system (PLC).

The “Handshake” Logic: Imagine your Rotary Packing Table is full.

Without Integration: The discharge conveyor keeps running, piling bags onto the floor or crushing them against the guide rails.

With Integration: A sensor on the table signals the conveyor to “Pause.” The conveyor signals the VFFS machine to “Hold.” The entire line pauses intelligently and resumes instantly when the table is cleared.

Variable Frequency Drives (VFDs): We equip our conveyors with VFDs to fine-tune the belt speed. This allows you to synchronize the conveyor exactly with the discharge rate of the weigher, preventing both starvation and pile-ups.

3. Material Selection and Efficiency

The physical application of the belt material itself plays a huge role in packaging line efficiency.

Friction Coefficients: Using a standard low-friction belt for an incline application will cause bags to slip back. Every slip is a potential jam that requires operator intervention.

Başvuru: Utilizing High-Friction Rough Top belts ensures 100% positive grip.

Changeover Downtime: In food plants, hygiene cleaning is the biggest downtime factor.

Başvuru: Using “Tool-less” removal designs or Modüler Plastik Kayışlar can reduce cleaning time from 40 minutes to 10 minutes. That is 30 minutes of extra production every day.

Conclusion: Engineering the Perfect Line

The belt conveyor role in packaging lines is foundational. It determines whether your expensive weighing and packing machines run at 60% capacity or 95% capacity.

By focusing on precise product flow control and smart conveyor integration, you turn a collection of machines into a unified, high-performance system.

Is your conveyor system holding you back? Don’t settle for bottlenecks. Let our engineers analyze your layout and propose an optimized application solution.