Introduction: The “First Mile” of Automation

When a packaging line underperforms, the blame often falls on the “star” equipment: the Multihead Weigher or the VFFS bagger. Engineers tweak the weigher’s vibration or adjust the bagger’s sealing time, yet the efficiency issues persist.

Why? Because the root cause is often upstream.

The problem is rarely the weighing machine itself; it is the Besleme Sistemi responsible for delivering the product to it.

In our experience as system integrators, we see a common pattern: factories invest heavily in weighing and packing but neglect the “First Mile.” They treat feeding systems in packaging lines as simple transport, ignoring the science of flow control. This article explains why shifting from “equipment thinking” to “system thinking” is critical for your OEE.

1. What Happens When Product Feeding Is Unstable

The Multihead Weigher is a precision instrument. To function correctly, it requires a consistent, predictable “curtain” of product.

When you have unstable product flow entering the scale, three critical issues destroy your line’s performance:

Starvation (Efficiency Loss): If the flow trickles or stops, the weigher’s top cone runs empty. The buckets cannot find a valid combination to meet the target weight. The machine pauses, waiting for product. Sonuç: You lose cycles and your Speed (PPM) drops.

Flooding (Accuracy Loss): If the flow surges unexpectedly, too much product is dumped onto the top cone. The linear pans become overwhelmed and cannot separate the product effectively. Sonuç: Overfilled buckets leading to “Overweight Rejects” (Giveaway) or machine jams.

Density Variation: For volumetric fillers, unstable feeding causes density changes (e.g., compacted vs. aerated powder), directly causing weight errors.

2. Common Feeding Problems Before Packaging

Before the product even reaches the scale, generic conveyors often fail to address specific material characteristics. These are the most common product feeding problems we encounter:

The “Clumping” Effect: Sticky products like gummy candies or marinated meat tend to stick together on standard belts. If they drop into the weigher as a giant ball, accuracy is impossible.

The “Bridging” Effect: Fine powders (like flour) or interlocking products (like leafy greens) can form a bridge over the hopper outlet, stopping flow completely until an operator manually hits the bin.

The “Segregation” Effect: When moving a pre-mixed blend (e.g., trail mix), poor feeding mechanics can cause heavy nuts to sink and light raisins to rise, ruining the mix ratio.

3. Why Conveying and Feeding Are Not the Same

This is the most critical concept for engineers to understand. The terms are often used interchangeably, but they serve completely different functions.

Conveying is Logistics (Moving): A standard conveyor’s job is to transport product from Point A to Point B. It focuses on distance. It is like a firehose—it delivers volume, but without precision.

Feeding is Control (Metering): A Feeding System is designed to regulate the rate Ve condition of the flow. It focuses on consistency. It is like a faucet valve—it controls exactly how much water comes out and how fast.

The System Thinking Shift: If you only buy “conveyors,” you are just connecting machines. If you implement automated feeding systems, you are controlling the process variables. You cannot fill a precision cup with a firehose; you need a valve.

4. How Feeding Systems Improve Line Stability

Upgrading from simple transport to engineered feeding solutions solves the instability issues mentioned above:

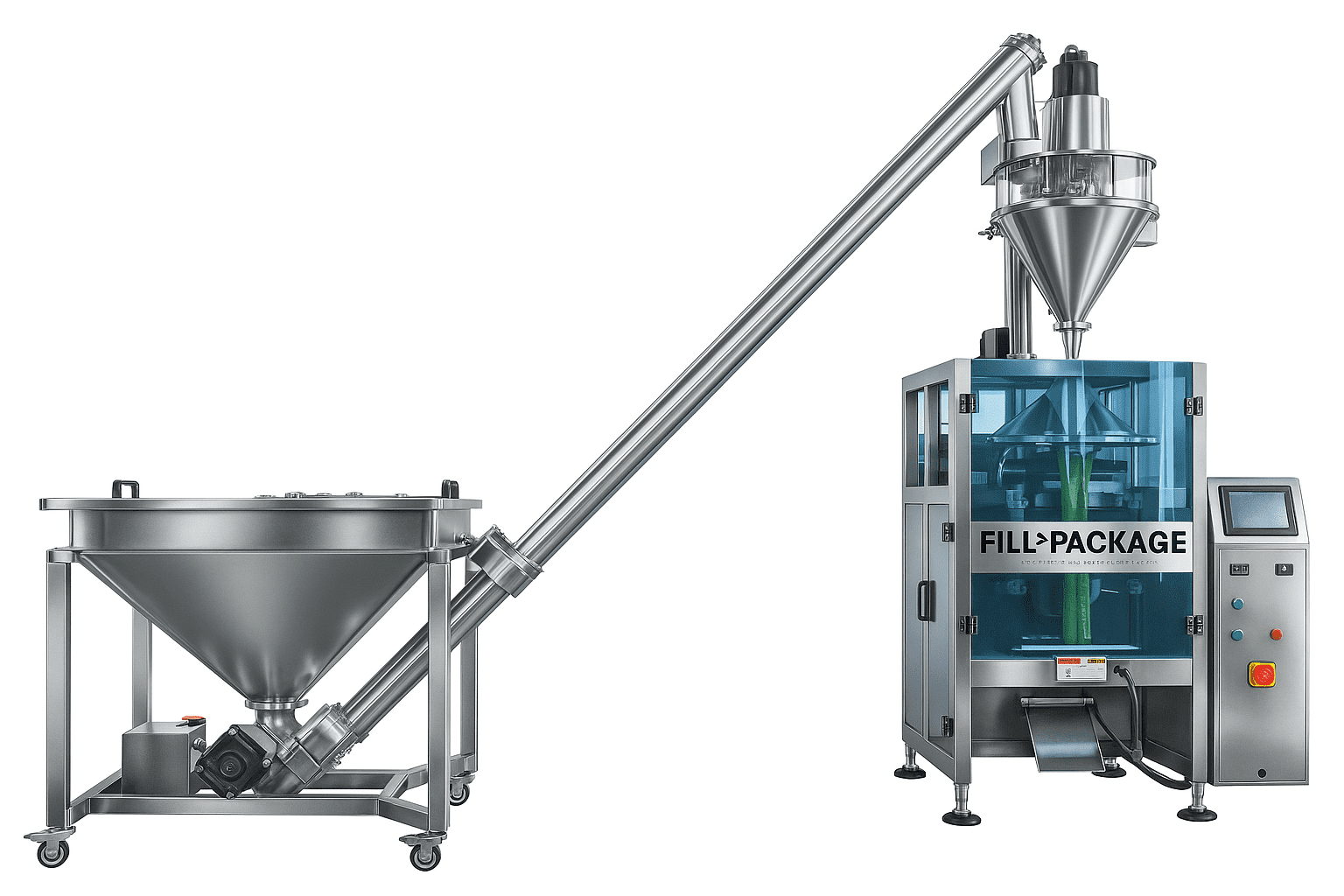

Precision Metering: Screw Feeders use a rotating auger to actively break bridges in powders, delivering a consistent density to the filler.

Product Distribution: Titreşimli Besleyiciler use gentle vibration to spread sticky or interlocking products into a single layer. This “de-clumping” action ensures the Multihead Weigher receives an even distribution for maximum accuracy.

Smart Integration: Modern feeding systems use “Handshake” logic. When the weigher signals it is full, the feeder stops instantly (not coasting to a stop). This creates a “Trickle Feed” effect that keeps the system perfectly balanced—never starving, never flooding.

Conclusion: Control the Flow, Control the Cost

Stability is money. By recognizing that Feeding ≠ Conveying, you can eliminate the fluctuations that cause giveaways and downtime.

Don’t let a generic belt compromise your high-precision packaging line. Upgrade to a system designed for control.

Ready to stabilize your packaging line? From Screw Feeders for powder to Vibratory Feeders for snacks, we engineer solutions that integrate seamlessly with your weighers.