Introducción

En la era industrial actual, en rápida evolución, el sector del envasado de alimentos está experimentando una transformación sin precedentes. Las crecientes exigencias de los consumidores en cuanto a seguridad alimentaria, calidad del producto y personalización, junto con el aumento de los costes laborales y una fuerte apuesta por la sostenibilidad, están sometiendo a las líneas de envasado tradicionales a una gran presión. La eficiencia, la precisión, la higiene y la fiabilidad se han convertido en los principales motores de crecimiento, y la tecnología inteligente se considera la clave para alcanzar estos objetivos.

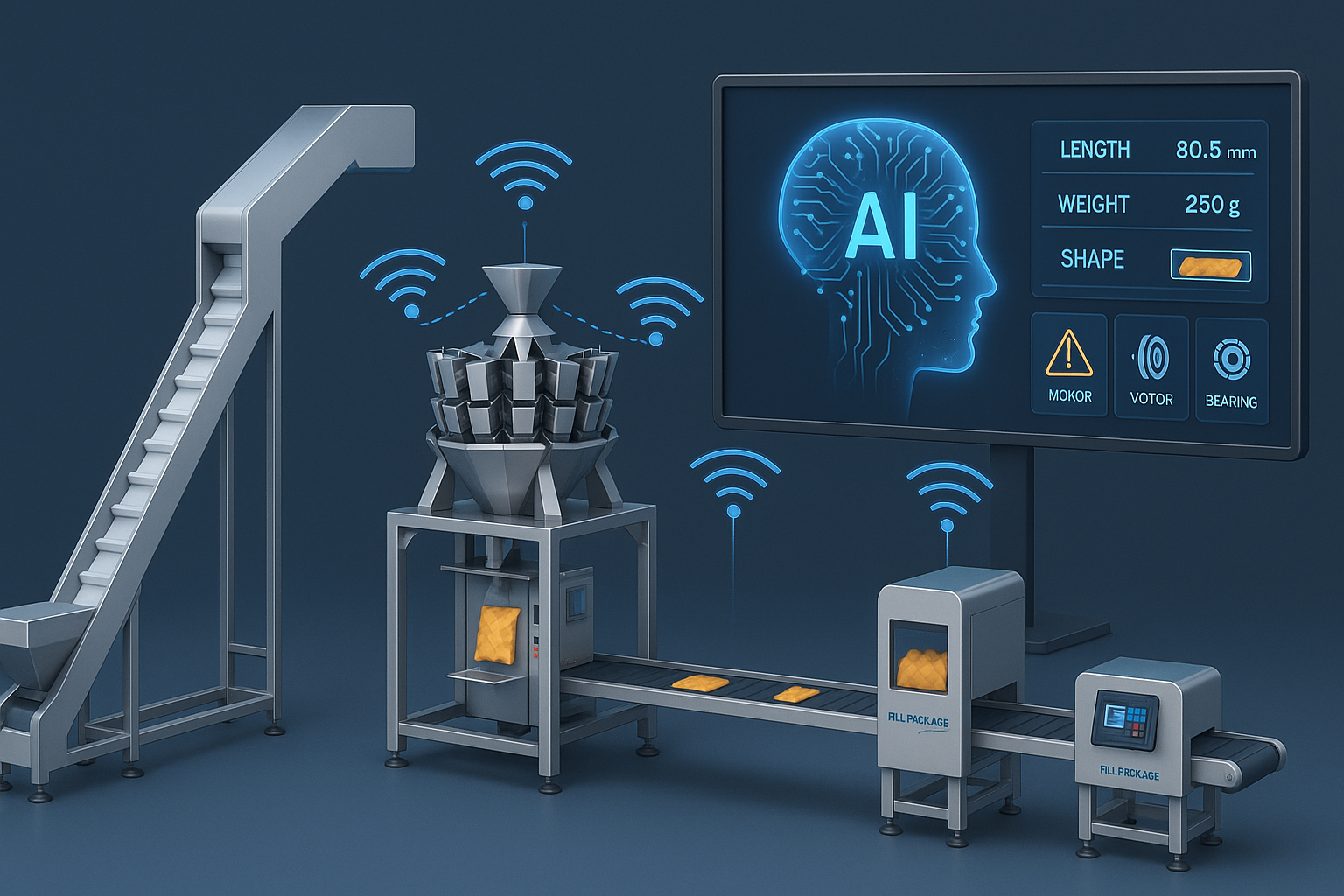

A la vanguardia de esta transformación, tecnologías disruptivas como la Inteligencia Artificial (IA), la automatización avanzada, el Internet de las Cosas (IdC) y el análisis de big data están transformando los procesos de fabricación a un ritmo acelerado. Estas tecnologías permiten que las máquinas perciban, aprendan y tomen decisiones, impulsando un control más preciso, operaciones eficientes y respuestas más inteligentes en cada etapa del proceso. sistema transportador de envasado de alimentos.

Como expertos con amplia experiencia en la fabricación de transportadores para envases de alimentos, FILL PACKAGE mantiene una visión clara de las tendencias futuras. Entendemos que simplemente proporcionar transportadores de alto rendimiento ya no es suficiente. Apostando por la innovación, hemos desarrollado una visión audaz para el futuro de los transportadores inteligentes para envases. Este artículo explora las perspectivas de FILL PACKAGE para 2030 y detalla cómo planeamos liderar la industria hacia una nueva era más inteligente, eficiente y sostenible.

Parte 1: La visión tecnológica de los transportadores de envasado de alimentos en 2030

El panorama de las cintas transportadoras de envasado de alimentos experimentará una profunda innovación tecnológica para 2030, caracterizada por la fusión de múltiples tecnologías de vanguardia. Los sistemas del futuro serán más inteligentes, rápidos, flexibles y sostenibles para satisfacer las complejas demandas del mercado y los estándares más estrictos de la industria.

Tendencias en inteligencia

La inteligencia va más allá de la mera automatización: los sistemas detectarán, analizarán, aprenderán y optimizarán de forma autónoma. La IA y el aprendizaje automático serán fundamentales:

El papel de la IA y el aprendizaje automático: La IA se integrará profundamente en las capas de control del sistema transportador, analizando grandes datos de producción (flujo de material, estado de la máquina, entorno, historial de fallas) para optimizar el rendimiento, predecir el mantenimiento y solucionar problemas de forma autónoma.

Visión artificial: La visión 3D de alta resolución combinada con el aprendizaje profundo permitirá el reconocimiento de productos a nivel de milisegundos para detectar forma, tamaño, color, defectos y contaminación, lo que garantiza la inspección de calidad 100% en línea.

Mantenimiento predictivo: Los sensores en motores, cojinetes y correas alimentarán modelos de IA que predicen el desgaste y la vida útil restante, cambiando el mantenimiento de reactivo a proactivo, reduciendo así el tiempo de inactividad y los costos.

Fuerzas impulsoras del desarrollo industrial

-

El aumento de los costos laborales y la escasez de mano de obra impulsan la demanda de automatización.

-

Las crecientes regulaciones de seguridad alimentaria requieren soluciones de envasado higiénicas y trazables.

-

Las tendencias del mercado hacia la producción personalizada y en lotes pequeños exigen sistemas de transporte flexibles y rápidamente reconfigurables.

Integración y optimización basada en datos

-

Las máquinas transportadoras y envasadoras (pesadoras multicabezal, VFFS, encajadoras, paletizadoras) se integrarán estrechamente bajo plataformas de control unificadas.

-

Los sensores de IoT permitirán la recopilación de datos en tiempo real y el análisis basado en IA optimizará el uso de energía, el rendimiento e identificará cuellos de botella.

-

La monitorización y el diagnóstico remotos a través de la nube y 5G garantizarán una rápida respuesta y tiempo de actividad del servicio.

Parte 2: Visión 2030 de FILL PACKAGE: Soluciones de transporte inteligentes

FILL PACKAGE se compromete a liderar la innovación en transportadores inteligentes para envasado de alimentos. Nuestra visión para 2030 se centra en el valor para el cliente y en ecosistemas tecnológicos, respaldados por:

-

Inversión en I+D+i: Centrado en control avanzado, detección de precisión, algoritmos de IA y nuevas aplicaciones de materiales.

-

Asociaciones: Colaborar con las principales organizaciones de inteligencia artificial, automatización e investigación a nivel mundial para acelerar la innovación.

-

Desarrollo del talento: Formar expertos multidisciplinarios en ingeniería, ciencia de datos y desarrollo de software.

Productos futuros

-

Pesadoras multicabezal inteligentes: Pesaje adaptativo impulsado por IA que optimiza la precisión y la velocidad según el producto y el entorno.

-

Avanzado Máquinas VFFS: Ajuste automático de parámetros (tensión de la película, temperatura de sellado) para reducción de desperdicios y calidad.

-

Inteligente Transportador Redes: Planificación dinámica de rutas, control de flujo y tolerancia a fallos mediante control central.

Innovaciones en servicios

-

Monitoreo remoto habilitado para IoT: Datos del equipo en tiempo real accesibles en cualquier momento.

-

Mantenimiento predictivo y alertas: Minimizar tiempos de inactividad inesperados.

-

Plataformas de clientes digitales: Soporte asistido por IA las 24 horas, los 7 días de la semana, recursos en línea y procesos de servicio optimizados.

Parte 3: Hoja de ruta y bases actuales

Nuestra visión se basa en años de experiencia en el sector, capacidades de diseño a medida y un servicio al cliente integral. Tenemos objetivos claros a corto plazo (2025-2027), mediano plazo (2027-2030) y largo plazo (después de 2030), centrados en la automatización, el análisis de datos, la integración de IA y los sistemas totalmente autónomos.

Priorizamos las asociaciones, el desarrollo de tecnología conjunta con los clientes y la participación en los esfuerzos de estandarización de la industria para garantizar un crecimiento sostenible.

Parte 4: Compromiso de valor con los clientes

FILL PACKAGE se compromete a:

-

Mejore drásticamente la eficiencia de la producción a través del flujo de material optimizado por IA.

-

Garantice una calidad de embalaje superior mediante visión artificial integrada.

-

Optimice costos con mantenimiento predictivo y gestión energética.

-

Proporcionar soporte proactivo basado en IoT garantizando operaciones ininterrumpidas.

Nuestro objetivo es ser su socio estratégico de confianza para soluciones de transporte de embalajes inteligentes, ayudándolo a mantenerse competitivo y preparado para los desafíos futuros.

Conclusión

Nuestra visión 2030 para transportadores inteligentes de envasado de alimentos se basa en un profundo conocimiento del sector y una innovación incesante. Creemos que las futuras líneas de producción serán altamente inteligentes, eficientes, flexibles y sostenibles.

Al combinar tecnologías de vanguardia con las necesidades del cliente y sistemas de servicio sólidos, FILL PACKAGE se compromete a transformar estas ambiciones en realidad, ofreciendo soluciones de envasado más seguras, inteligentes y rentables en todo el mundo.

Llamada a la acción

¿Le entusiasma el futuro de las cintas transportadoras para envasado de alimentos? ¿Quiere colaborar con un líder vanguardista y con gran experiencia tecnológica?

-

Siga las actualizaciones técnicas de FILL PACKAGE: Visita www.fill-package.com

-

Colaborar en tecnología del futuro: Contacte con nuestro equipo de I+D para explorar oportunidades de innovación

-

Conéctese con nuestros expertos: Analice cómo podemos ayudarle a mejorar la eficiencia y confiabilidad de su línea de producción.

¡Unámonos para dar forma a un futuro de embalaje más inteligente, eficiente y sostenible!

Descargo de responsabilidad

Este artículo describe la visión de FILL PACKAGE con base en las tendencias tecnológicas actuales y las expectativas del mercado. El despliegue tecnológico real puede variar según los avances y las particularidades del proyecto. FILL PACKAGE se compromete con esfuerzos continuos de I+D, pero no garantiza el plazo ni los resultados finales. El contenido es meramente informativo.