Introduction: It’s Not Just About Moving Products

If you are a machine manufacturer (OEM) or a factory manager, you know that a packaging line is only as fast as its slowest transfer point. You can have the world’s fastest Multihead Weigher, but if the feeding conveyor bridges or the takeaway belt bottlenecks, your OEE (Overall Equipment Effectiveness) plummets.

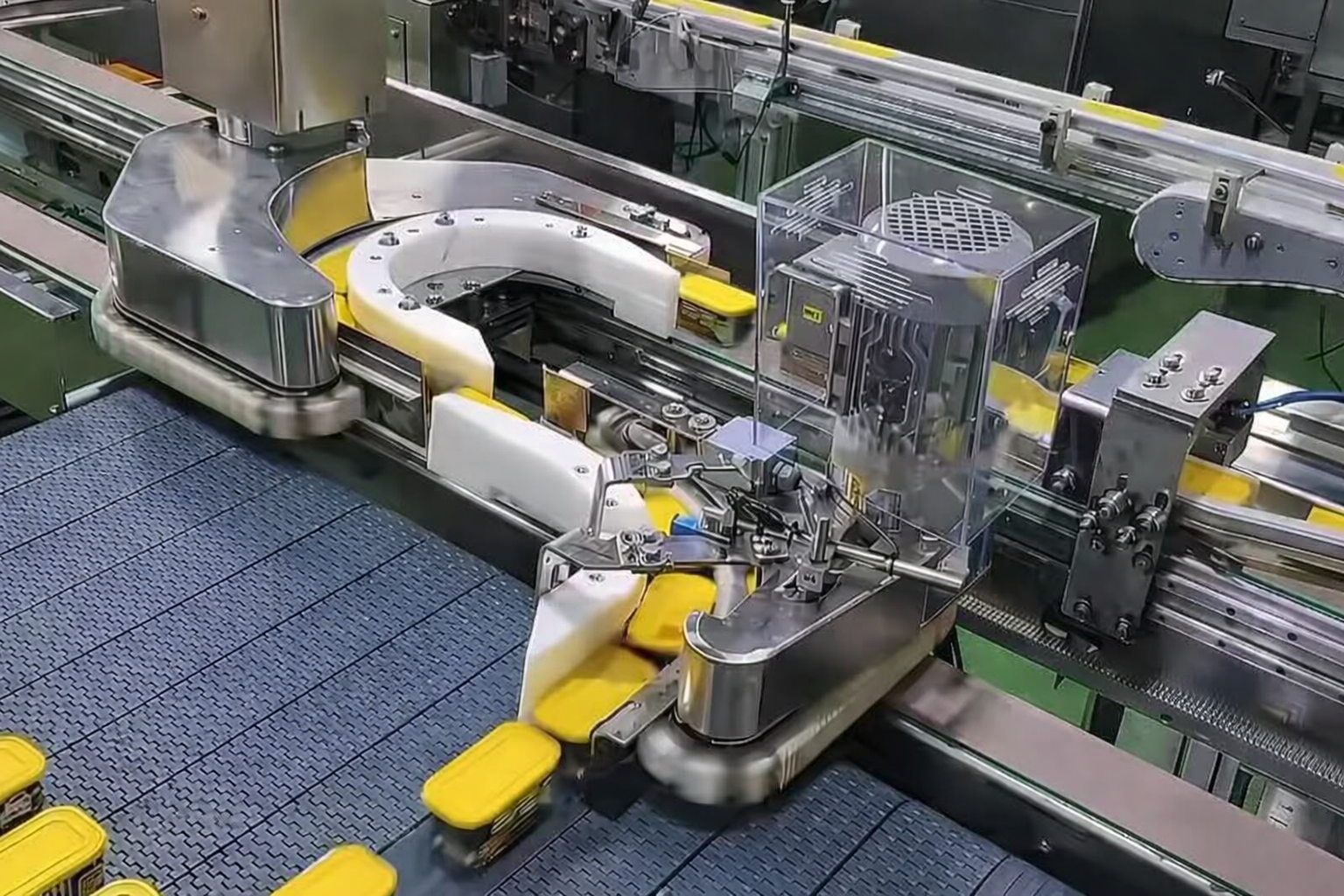

Designing an efficient conveyor system is not just about connecting Machine A to Machine B. It requires a deep understanding of physics, logic, and hygiene.

At Fill Package, we approach conveyor design as a science. Based on our experience integrating hundreds of food packaging lines, here is our 4-step engineering guide to designing a system that delivers maximum throughput.

Step 1: Analyze the “Physics” of Your Material

Before drawing a single line on a CAD layout, you must understand how the product behaves in motion. Static dimensions are not enough.

Текучесть: Is your product free-flowing (like rice) or cohesive (like milk powder)?

Engineering Tip: For powders that bridge, standard belts fail. You need a Гибкий винтовой конвейер with a center-coreless auger to actively force material forward

Хрупкость: Will the product break if dropped?

Engineering Tip: For potato chips or cookies, avoid drop transfers. Использовать Fastback Vibratory Conveyors that glide products forward using horizontal motion, ensuring zero breakage and no loss of seasoning.

Состояние поверхности: Is it sticky, oily, or frozen?

Engineering Tip: Fresh meat requires Модульные пластиковые ремни or specialized dimpled surfaces to prevent adhesion. Standard PU belts will cause hygiene nightmare

Step 2: Calculate the “Speed Chain” & Buffering

The most common design error is Speed Mismatch. A robust design uses a “V-Curve” or “Pull” philosophy, but it must be supported by accumulation.

The Math: Your downstream capacity should generally be 10-15% higher than your upstream supply to create a gap and prevent blockage.

The Buffer Zone: You cannot rely on perfect synchronization. Machines stop for film changes or label refills.

Design Requirement: You must calculate the necessary Accumulation Time (e.g., 2 minutes of buffer). We design accumulation tables or low-friction buffering conveyors to “store” product during these micro-stops, keeping your upstream weighers running continuously.

Step 3: Optimize Layout for Hygiene & Ergonomics

For food factories, the physical design must balance footprint with cleanability.

The “Open Frame” Rule: Never accept conveyors with closed hollow tubing where bacteria can hide. Specify Open Frame (Cantilever) Design. This allows operators to remove belts without tools and wash down the entire frame from all angles

Elevation Strategy: Don’t waste floor space. Использовать Z-Bucket Elevators или Incline Belt Conveyors to move product vertically, saving valuable ground floor square footage for operators and forklifts.

Step 4: Define the “Handshake” Logic (Controls)

A pile of steel is not a system until it has a brain. For OEMs and Integrators, this is the critical step.

Interlocks: The conveyor must not be a “dumb” motor. It needs to receive “Ready to Receive” signals from the downstream case packer and “Ready to Dump” signals from the upstream weigher.

Smart Sensors: Install photo-eyes to detect product backup.

Logic: If the sensor sees a backup for 3 seconds -> Slow down VFD to 50%. If backup persists for 10 seconds -> Stop Feed. This automated logic prevents product crushing and spillage.

Conclusion: Partner with a System Expert

Designing a conveyor system involves complex variables—from friction coefficients to PLC handshake protocols.

Для Machine Distributors and OEMs, partnering with a specialized conveyor manufacturer means you can focus on your core technology while we handle the material flow logistics. For Factory Managers, it means a production line that hits its ROI targets faster.

Don’t leave your line efficiency to chance.

[CTA Section]

Need a Layout Simulation? Send us your factory floor plan and product details. Our engineering team will provide a Free 3D Layout & Flow Analysis to demonstrate how we can optimize your packaging line.