To provide you with a comprehensive overview of our robust quality systems, we will be presenting a 9-part blog series. We are confident that this will offer valuable insights into our processes for ensuring excellence.

Why Material Matters in Food Packaging Machines

की दुनिया में खाद्य पैकेजिंग मशीनें-से वाहक पट्टा को पाउच पैकेजिंग मशीनें—the choice of material directly impacts durability, hygiene, and overall performance. For industries like pet food processing, where safety and consistency are critical, stainless steel is often the first choice. But not all stainless steel is the same. Among the most commonly used are 304 स्टेनलेस स्टील और 201 स्टेनलेस स्टील. Knowing the difference between them helps you make smarter investments.

304 vs 201 Stainless Steel: Key Comparisons

1. Corrosion Resistance

- 304 Stainless Steel: Excellent resistance to rust and corrosion. Ideal for environments with moisture, oils, and even mild acids—conditions often found in pet food and general food production lines.

- 201 Stainless Steel: Lower nickel content, replaced by manganese and nitrogen. More affordable but less resistant to corrosion, especially in humid or salty environments.

👉 बख्शीश: If your packaging line involves frozen or high-moisture foods like pet food, seafood, or sauces, 304 stainless steel is the safer choice for long-term durability.

Salt-Spray-Test

2. Durability & Strength

- 304: Strong, highly durable, and resistant to cracking, making it perfect for belt conveyor systems, बाल्टी लिफ्ट, और flow wrapper frames that run continuously.

- 201: Harder but more brittle, which may lead to faster wear in high-load or high-friction applications.

👉 बख्शीश: के लिए बहु-सिर वाले तौलने वाले, रैखिक तौलने वाले, या पाउच पैकेजिंग मशीनें, 304 stainless steel provides better stability and longer service life.

3. Cost Effectiveness

- 201 Stainless Steel: More affordable, suitable for cost-sensitive projects or environments with minimal exposure to moisture.

- 304 Stainless Steel: Higher upfront investment, but lower long-term maintenance costs due to its excellent resistance to rust and wear.

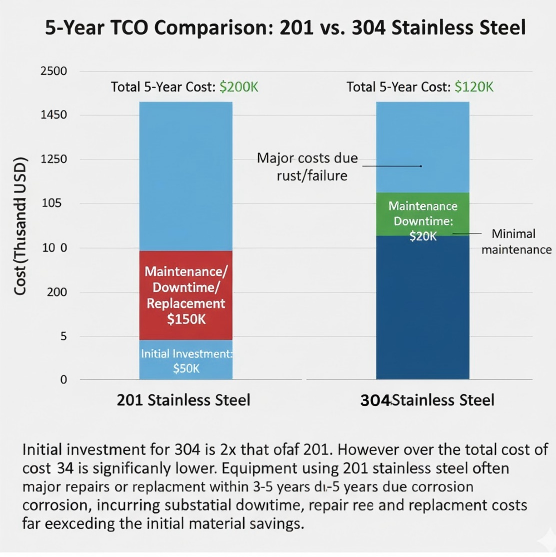

👉 बख्शीश: When evaluating पैकेजिंग मशीनें for snacks, चिप्स पैकेजिंग मशीनें, या पालतू भोजन पैकेजिंग उपकरण, calculate the total cost of ownership (TCO), not just the purchase price.

Applications in Food Packaging

- Pet Food Packaging Machines: 304 stainless steel ensures food safety and prevents contamination.

- Chips Packaging Machine: Since oil and salt accelerate corrosion, 304 is the preferred choice to maintain hygiene and extend machine lifespan.

- Belt Conveyor / Modular Belt Conveyor: Strong resistance to abrasion and easy to clean, suitable for continuous food transport.

- Bucket Elevator & Working Platform: Reliable material strength ensures stability in heavy-duty packaging lines.

- Flow Wrapper & Pouch Packaging Machines: Smooth surface reduces friction, ensures precise sealing, and minimizes maintenance.

- Check Weigher Machine & Metal Detector: Long-lasting accuracy and compliance with food safety standards.

- Spare Parts & Bowl Conveyor: Using 304 stainless steel components helps minimize downtime and replacement costs

Why 304 Stainless Steel Is the Smarter Choice for Packaging Equipment

- Food Safety First – 304 stainless steel is FDA-approved and highly resistant to corrosion, making it ideal for direct food contact.

- Longer Machine Lifespan – Stronger mechanical properties reduce the need for frequent replacements, saving you money.

- Lower TCO (Total Cost of Ownership) – While 201 may look cheaper at first glance, the higher maintenance, spare part replacement, and downtime often make it costlier in the long run.

- Better Hygiene & Cleaning – The smoother surface of 304 steel makes it easier to clean, preventing bacterial growth and ensuring compliance with खाद्य पैकेजिंग मशीनरी मानकों.

Practical Advice for Buyers

When evaluating खाद्य पैकेजिंग उपकरण suppliers, here are a few tips to avoid common pitfalls:

- Look beyond the price tag – Calculate the TCO (purchase cost + shipping + insurance + duties + installation + training + energy + maintenance + spare parts + downtime).

- Check certifications – Ensure the stainless steel and overall equipment comply with food safety standards such as CE, FDA, or 3-A.

- Request detailed material specifications – Verify whether the supplier is using 304 स्टेनलेस स्टील in all food-contact and critical areas.

- Think long term – For high-output applications like a आलू के चिप्स पैकिंग मशीन or high-speed automatic food packaging machine, durability and hygiene outweigh small upfront savings.

Final Thoughts: Quality is the Best Investment

की दुनिया में industrial packaging machines, the materials you choose today will shape your production efficiency, maintenance costs, and brand reputation tomorrow. While 201 स्टेनलेस स्टील may reduce your initial spend, 304 स्टेनलेस स्टील delivers reliability, hygiene, and long-term savings—especially in industries like snacks, chips packaging, frozen food, and pet food.

पर भरें-पैकेज (www.fill-package.com), we understand the importance of material selection in equipment design. Our वाहक पट्टा, मॉड्यूलर बेल्ट कन्वेयर, बाल्टी लिफ्ट, कार्य प्लेटफार्मों, रोटरी पैकिंग टेबल, मल्टीहेड वेयर्स, linear weighers, sachet counting machines, पाउच पैकेजिंग मशीनें, वीएफएफएस मशीनें, spare parts, और धातु डिटेक्टरों are built with food-grade stainless steel to deliver long-term reliability and hygiene.

💡 What’s your biggest challenge when choosing materials for your packaging equipment—cost, durability, or compliance? Share your thoughts in the comments below!