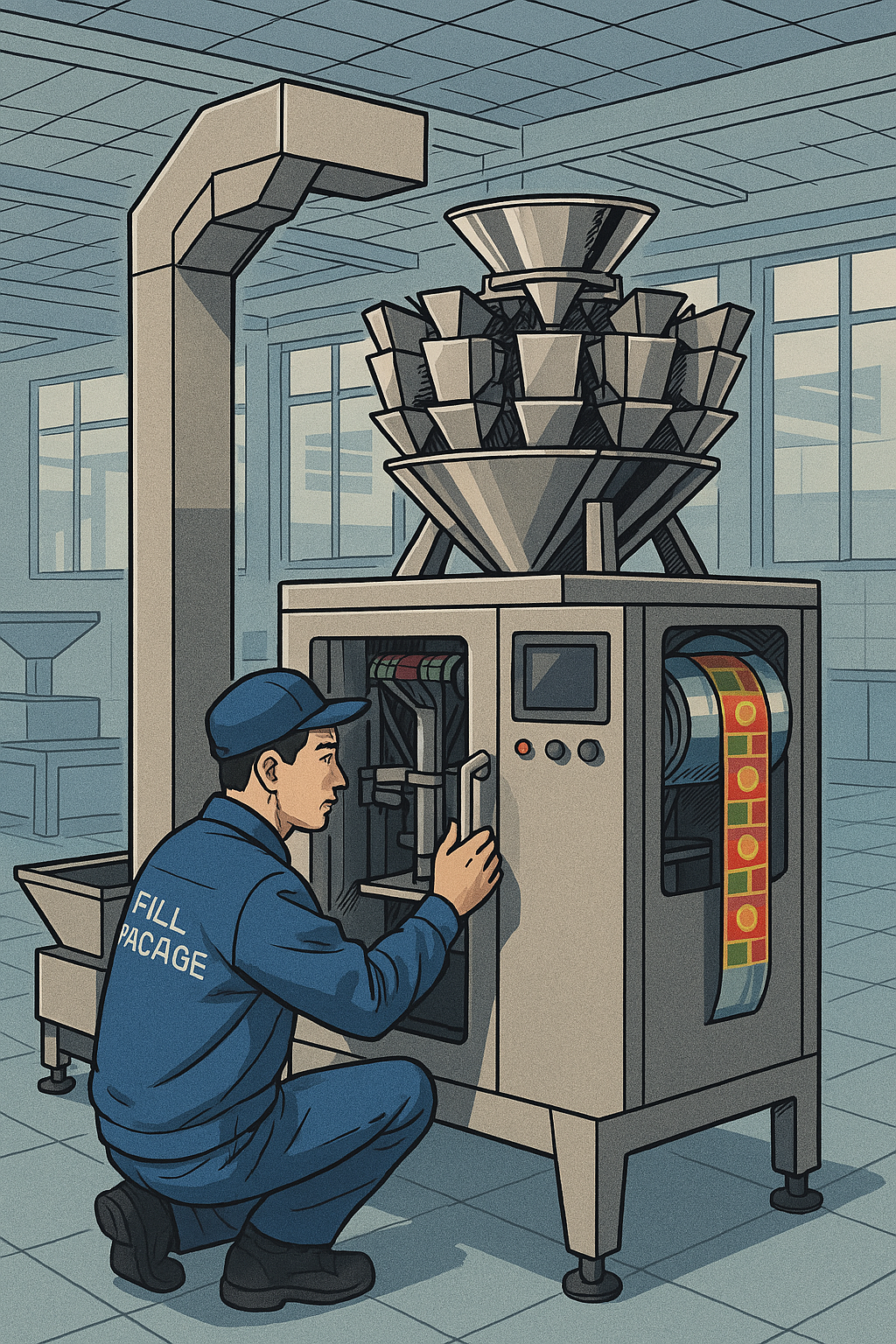

आज के तेज़ी से बढ़ते खाद्य प्रसंस्करण और पैकेजिंग उद्योग में, उच्च दक्षता और सटीकता प्राप्त करना सफलता के लिए अत्यंत महत्वपूर्ण है। पारंपरिक मैनुअल तौल और पैकेजिंग विधियाँ अक्सर बढ़ती बाज़ार माँगों और कड़े गुणवत्ता मानकों को पूरा करने में विफल रहती हैं। मल्टीहेड वेयर्स का आगमन, एक क्रांतिकारी तकनीक जो आधुनिक पैकेजिंग श्रृंखलाओं की आधारशिला बन गई है। असाधारण प्रदर्शन के साथ, इन उपकरणों ने पैकेजिंग प्रक्रिया को पूरी तरह से बदल दिया है, उत्पादकता में उल्लेखनीय सुधार किया है और लागत कम की है। यह मार्गदर्शिका मल्टीहेड वेयर्स, उनके सिद्धांतों, प्रकारों, लाभों और बहुमुखी अनुप्रयोगों पर गहन जानकारी प्रदान करेगी, जिससे आप अपनी पैकेजिंग आवश्यकताओं के लिए सही समाधान चुन सकेंगे।

संयोजन तौल की कला

मल्टीहेड वेयर्स गति और सटीकता का अद्भुत सम्मिश्रण करते हुए, एक सरल संयोजन तौल सिद्धांत का लाभ उठाएँ। संभाव्यता सिद्धांत और बुद्धिमान एल्गोरिदम का उपयोग करते हुए, ये मशीनें सटीक लक्ष्य भार प्राप्त करने के लिए कई अलग-अलग तौल इकाइयों से भारों का सर्वोत्तम संयोजन चुनती हैं। स्वचालन मैन्युअल हस्तक्षेप को महत्वपूर्ण रूप से कम करता है और त्रुटियों को कम करता है।

एक विशिष्ट बहु-सिर वाला तौलने वाला के होते हैं:

- केंद्रीय फ़ीड हॉपर और मुख्य कंपन प्लेट: उत्पादों को अलग-अलग फीडरों में समान रूप से वितरित करता है।

- रैखिक फीडर और वजन मापने वाले हॉपर: अस्थायी रूप से भंडारण करें और उत्पादों को सुचारू रूप से तौलने वाले हॉपर में डालें।

- वजन मापने वाले हॉपर और सेंसर: उत्पाद का वजन सटीक रूप से मापें.

- केंद्रीय प्रोसेसर और एल्गोरिदम: शीघ्रता से इष्टतम संयोजनों की गणना करें।

- निर्वहन और पैकेजिंग एकीकरण: निर्बाध समन्वय सुनिश्चित करें कन्वेयर बेल्ट पैकेजिंग सिस्टम.

संयोजन वजन क्यों मायने रखता है:

- अत्यधिक सटीकता: वजन विचलन को न्यूनतम करता है (उदाहरण के लिए, ±0.1 ग्राम).

- बेहतर गति: एक साथ वजन और गणना को तेजी से संभालता है।

- उत्पाद बहुमुखी प्रतिभा: दानेदार, नाजुक, चिपचिपे या अनियमित आकार की वस्तुओं के लिए समायोजन करता है।

मल्टीहेड वेइगर के प्रकार

मल्टीहेड वेइगर विभिन्न आवश्यकताओं के अनुरूप विभिन्न रूपों में आते हैं:

वजन प्रणाली द्वारा:

- वॉल्यूमेट्रिक मल्टीहेड वेइगर: मात्रा द्वारा माप, कम सटीकता आवश्यकताओं वाले उत्पादों के लिए उपयुक्त।

- सेंसर-आधारित मल्टीहेड वेइर्स: उन्नत सेंसर के माध्यम से सटीक वजन प्रदान करें।

सिरों की संख्या के अनुसार:

- 8 से 24 सिरों तक की रेंज, जो गति और परिशुद्धता को प्रभावित करती है।

- लोकप्रिय कॉन्फ़िगरेशन: 10, 14, 16 सिर.

क्षमता के अनुसार:

- छोटी क्षमता: स्नैक्स, चाय और कैंडी के लिए आदर्श।

- बड़ी क्षमता: अनाज या पालतू भोजन जैसे बड़े पैक के लिए उपयुक्त।

उत्पाद प्रकार के अनुसार:

- सूखे, दानेदार, गीले, चिपचिपे या नाजुक उत्पादों के लिए अनुकूलित।

फीडिंग सिस्टम द्वारा:

-

- थरथानेवाला, बेल्ट, या स्क्रू फीडर विभिन्न उत्पाद विशेषताओं को पूरा करना।

नियंत्रण प्रणाली द्वारा:

- डिजिटल प्रणालियाँ उन्नत, उपयोगकर्ता-अनुकूल इंटरफेस और डेटा प्रबंधन प्रदान करती हैं।

मल्टीहेड वेइर्स उद्योग में अग्रणी क्यों हैं?

मल्टीहेड वेयर्स अपने विशिष्ट लाभों के कारण उद्योगों में इन्हें पसंद किया जाता है:

- उच्च गति संचालन: प्रति मिनट 200 पैकेज तक।

- असाधारण परिशुद्धता: उत्पाद अपशिष्ट को कम करता है, मानकों के अनुपालन को बढ़ाता है।

- बहुमुखी प्रतिभा और लचीलापन: विविध उत्पादों के लिए आसान समायोजन।

- उपयोगकर्ता-अनुकूल संचालन: सरल, सहज स्पर्श स्क्रीन प्रशिक्षण की आवश्यकताओं को कम कर देती है।

- स्थायित्व और कम रखरखाव: औद्योगिक परिस्थितियों के लिए निर्मित, मॉड्यूलर डिजाइन आसान रखरखाव की सुविधा प्रदान करते हैं।

- महत्वपूर्ण श्रम लागत बचत: पारंपरिक रूप से मैन्युअल रूप से किए जाने वाले कार्यों को स्वचालित करता है, जिससे परिचालन दक्षता में सुधार होता है।

- मिश्रण और सम्मिश्रण क्षमताएं: विभिन्न उत्पादों को सटीक अनुपात में सटीक रूप से संयोजित करता है।

मल्टीहेड वेइयर्स के व्यापक अनुप्रयोग

मल्टीहेड वेयर्स का विभिन्न क्षेत्रों में व्यापक अनुप्रयोग है:

- खाद्य उद्योग: स्नैक्स, ताजा उपज, जमे हुए खाद्य पदार्थ, बेकरी उत्पाद, अनाज।

- दवा उद्योग: गोलियों, कैप्सूल, कणिकाओं की सटीक पैकेजिंग।

- गैर-खाद्य उद्योग: पालतू पशुओं का भोजन, हार्डवेयर घटक, प्लास्टिक कणिकाएँ, बीज, उर्वरक, छोटे खिलौने।

उनकी अनुकूलनशीलता दानेदार, ब्लॉक, पाउडर और मिश्रित उत्पादों के प्रभावी संचालन को सुनिश्चित करती है।

समर्थित सामान्य पैकेजिंग प्रारूप

मल्टीहेड वेइर्स विभिन्न पैकेजिंग मशीनों के साथ आसानी से एकीकृत हो जाते हैं, तथा विविध पैकेजिंग प्रारूपों को समायोजित कर लेते हैं:

- तकिया बैग: स्नैक्स, कैंडीज.

- स्टैंड-अप पाउच: कॉफी, पालतू भोजन.

- गसेट बैग: विस्तारित क्षमता और स्थिरता.

- ब्लॉक बॉटम बैग: आटे जैसे थोक उत्पादों के लिए स्थिरता।

- ड्वॉय पैक: पुन: प्रयोज्य, उपभोक्ता-अनुकूल पैकेजिंग।

- ज़िपर बैग: सुविधाजनक पुनः सील करने की सुविधा.

- बैग-इन-बैग: मल्टीपैक व्यवस्था.

निष्कर्ष

मल्टीहेड वेइंग मशीन आधुनिक पैकेजिंग तकनीक में एक महत्वपूर्ण प्रगति का प्रतिनिधित्व करती हैं। ये केवल वज़न मापने वाले उपकरण ही नहीं हैं, बल्कि ये बुद्धिमान निर्माण का प्रतीक हैं, जो उच्च गति, सटीक, लचीले और कुशल पैकेजिंग समाधान प्रदान करते हैं। ये उत्पाद की गुणवत्ता सुनिश्चित करते हैं, उपभोक्ता संतुष्टि बढ़ाते हैं और कंपनियों को कड़े उद्योग मानकों का पालन करने में मदद करते हैं।

चाहे आप नाजुक आलू के चिप्स, चिपचिपी कैंडीज, या सटीक सामग्री मिश्रण की पैकेजिंग कर रहे हों, बहु-सिर वाले तौलने वाले अनुकूलित समाधान प्रदान करें। अपनी विशिष्ट आवश्यकताओं को समझकर और फिल-पैकेज जैसे विशेषज्ञ आपूर्तिकर्ताओं के साथ जुड़कर, आप अपनी उत्पादन प्रक्रिया को अनुकूलित करने और प्रतिस्पर्धात्मक बढ़त हासिल करने के लिए उन्नत तौल तकनीक का लाभ उठा सकते हैं।

क्या आप अपनी पैकेजिंग दक्षता बढ़ाने के लिए तैयार हैं?

👉 आज ही हमारे विशेषज्ञों की टीम से संपर्क करें! जानें कि कैसे हमारे मल्टीहेड वजन समाधान आपकी उत्पादन सटीकता, दक्षता और समग्र लाभप्रदता को बढ़ा सकते हैं।